2004-2008 RX-8 - REPAIR PROCEDURE - RECALL 1017E

A. VEHICLE INSPECTION PROCEDURE

1.

Verify that the vehicle is within the following range:

Model Year

VIN Range

Build Date Range

2004-2008

JM1 FE**** 40 100053 – 140891

From April 10, 2003 through

February 18, 2008

JM1 FE**** 50 140892 – 161178

JM1 FE**** 60 200013 – 207471

JM1 FE**** 70 207473 – 214011

JM1 FE**** 80 214012 – 216619

-

If the vehicle is within the above range, proceed to Step 2.

-

If the vehicle is not within the above range, return vehicle to the customer or inventory.

2.

Perform a Warranty Vehicle Inquiry using your eMDCS System and inspect vehicle for Campaign Labels Recall

0516J and 1017E attached to the vehicle’s hood or bulkhead. Refer to eMDCS System - Warranty Vehicle

Inquiry Results

table below.

NOTE: Be sure to verify Recall number as the vehicle may have multiple Recall labels.

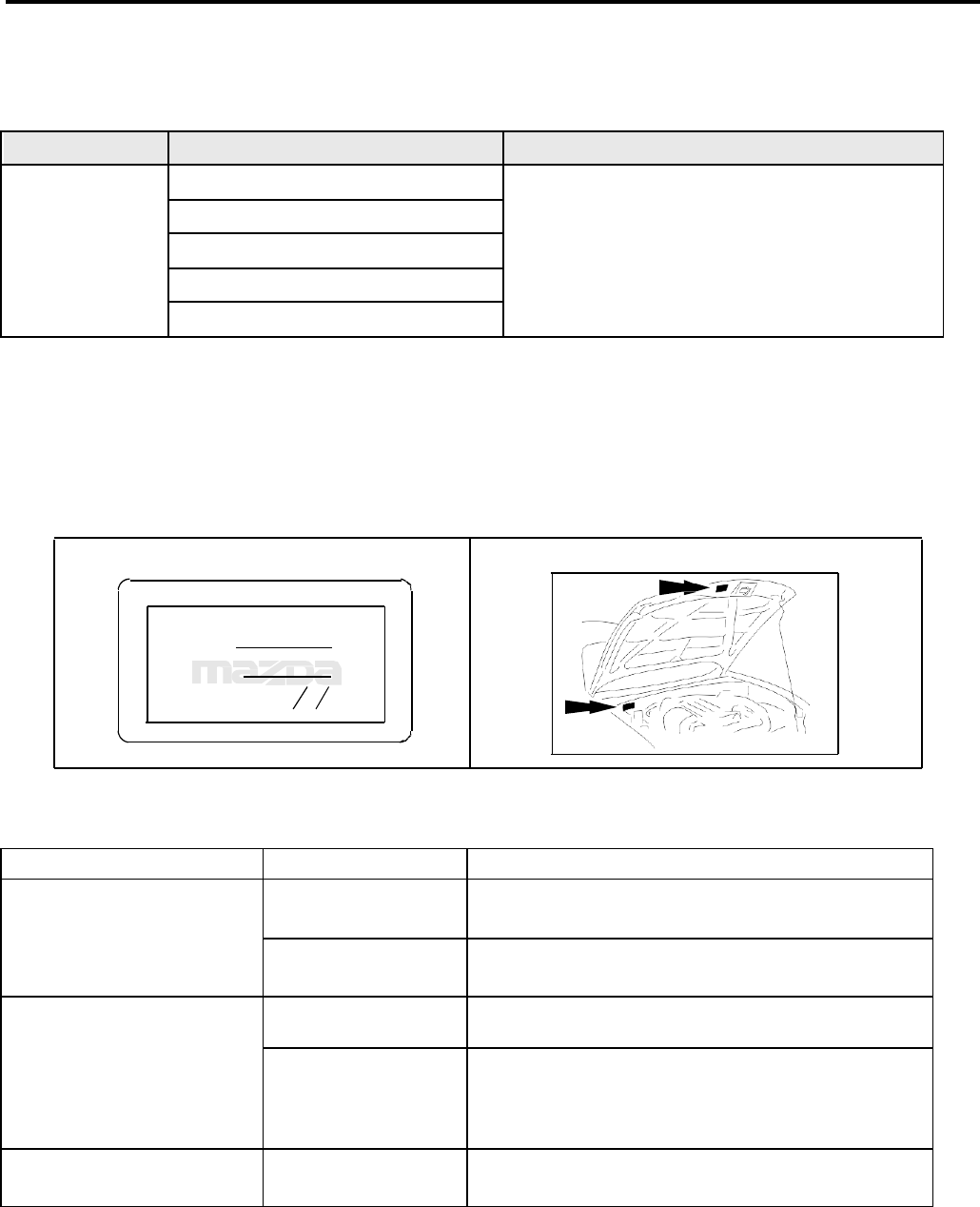

CAMPA IGN LABEL

CAMPAIGN NO:

DEALER C ODE:

DATE:

P/N 9999-95-065A-06

1326b

campaign_label

eMDCS System - Warranty Vehicle Inquiry Results:

If eMDCS displays:

Campaign Label is:

Action to perform:

RECALL 1017E OPEN and

RECALL 0516J is not

present

Present

Contact the Warranty Hotline at (877) 727-6626 op-

tion 3 to update vehicle history.

Not present

Proceed to “FUEL PUMP REPLACEMENT

PROCEDURE”.

RECALL 0516J CLOSED

and RECALL 1017E OPEN

Both labels are Present

Contact the Warranty Hotline at (877) 727-6626 op-

tion 3 to update vehicle history.

Not present

Proceed to “FUEL PUMP REPLACEMENT

PROCEDURE PAYING ATTENTION TO THE

NOTES REGARDING 0516J IN THE REPAIR

PROCEDURE

RECALL 0516J is not

displayed

Does not apply

Recall does not apply to this vehicle. Return vehicle

to inventory or customer.

Page 1 of 18

Page 2 of 18

B.

REPAIR PROCEDURE

“Fuel pump Ring recall campaign” and “Fuel Pump Discharge Pipe Crack” - Combined

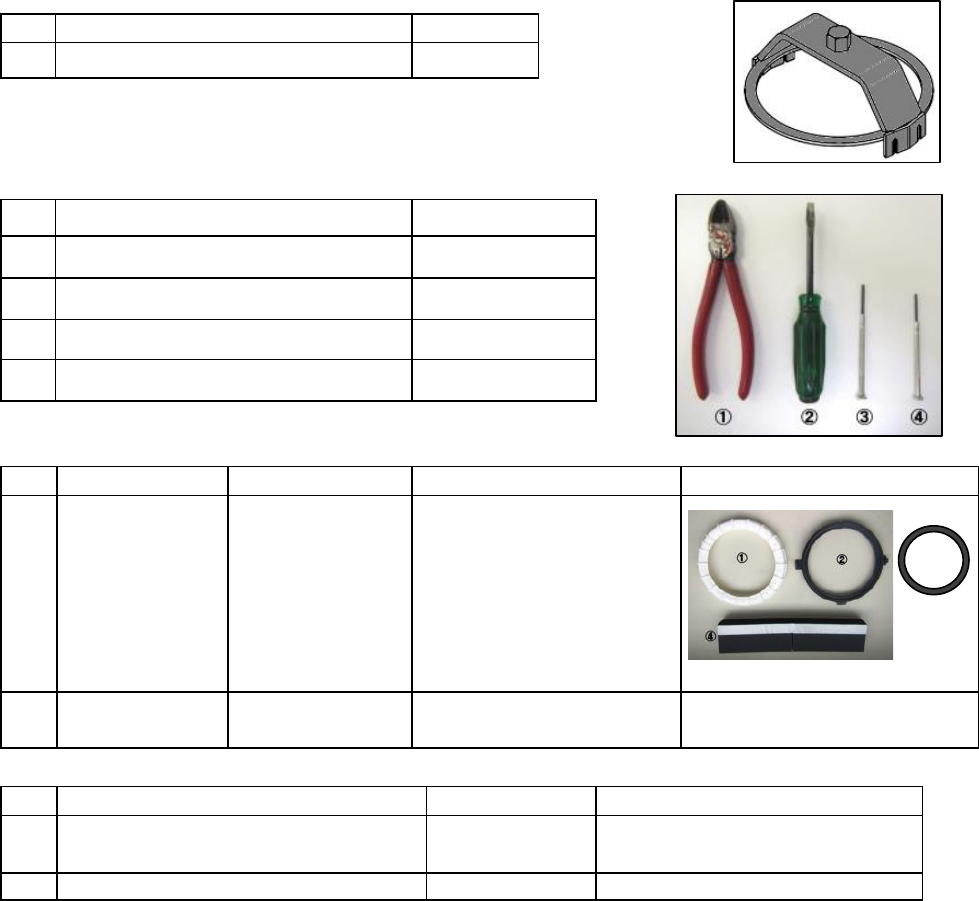

TOOL INFORMATION

Special Tool

No.

Special tool Name

Qty.

①

Fuel Pump Ring Wrench

1

This tool is used at Recall Campaign: Fuel Leak at Fuel Pump Rings

Required tools

No. Tool Name Note

① Diagonal cutting pliers -

② Flathead screwdriver -

③ Small flathead screwdriver (A) 2.3 mm

④ Small flathead screwdriver (B) 2.0 mm

Parts Information 1017E is open and recall 0516J is not displayed in eMDCS

No.

Part Name

Part Number

Component

Remark

①

Fuel pump ring

kit

(union nut)

F1Y1-42-A1X

Fuel pump ring 2pcs

Retainer 2pcs

Fuel Pump Ring Gasket

2pcs

Heat Insulation Pad 2pcs

②

Fuel pump

filter body kit

N3Y1-13ZE0C

Fuel filter body 1pc

Gasket 2pcs

Parts Information – Recall 0516J is closed and 1017E is open

No.

Part Name

Part Number

Component

①

Fuel pump filter body kit

N3Y1-13ZE0C

Fuel filter body 1pc

Gasket 2pcs

②

Fuel pump ring gasket

BN8F-42166

1pcs (Need main side only)

PROCEDURE

1. Perform the fuel line safety procedure.

WARNING

Fuel is extremely flammable. Always keep sparks and flame away from fuel. Ignition may cause death

or serious injury, or damage to equipment.

Fuel line spills and leakage from the pressurized fuel system are dangerous. Fuel can ignite and cause

serious injury or death and damage. Fuel can also irritate skin and eyes. To prevent this, always

complete the "Fuel Line Safety Procedure".

A person charged with static electricity could cause a fire or explosion, resulting in death or serious

injury. Before performing work on the fuel system, discharge static electricity by touching the vehicle

body.

CAUTION

If there is foreign material on the connecting area of the quick release connector, it might damage the

connector or fuel pipe. To prevent this, when the quick release connector has been disconnected,

clean the connecting area before reconnecting it.

①

③

Page 3 of 18

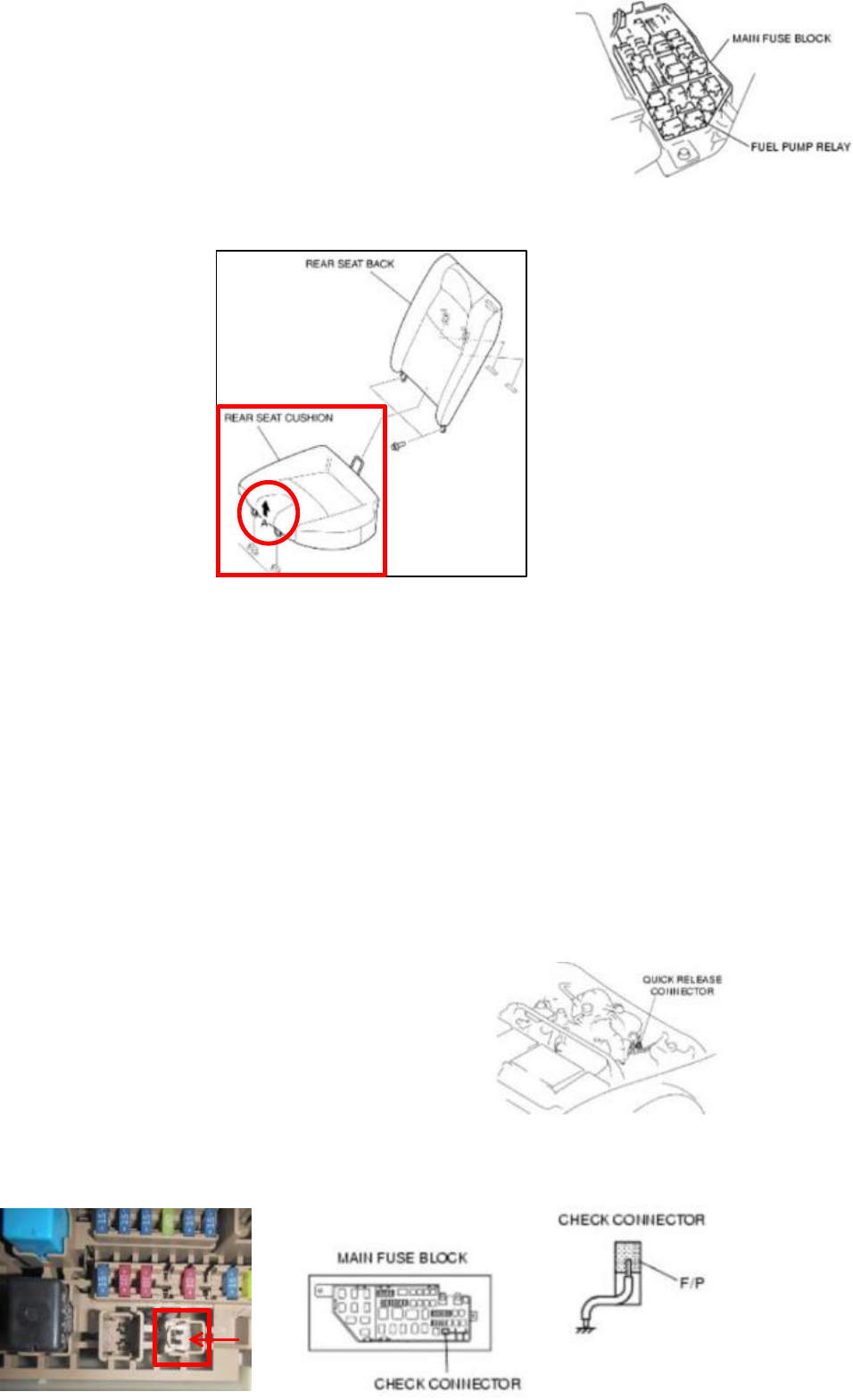

Fuel Line Safety Procedure

1) Remove the fuel-filler cap to release the pressure inside the fuel tank.

2) Remove the fuel pump relay.

3) Start the engine.

4) After the engine stalls, crank the engine several times.

5) Turn the ignition switch to the LOCK position.

6) Install the fuel pump relay.

2. Remove the rear seat cushion.(Both right and left sides)

Lift the point A in the direction of the arrow and then remove the rear seat cushion.

3. Remove the service-hole cover.

4. Check the fuel gauge indication.

NOTE: If the fuel gauge indicates 1/4 or less, go to Step 6 skipping Step 5.

5. Drain fuel from the fuel tank. (Only when the fuel gauge indicates 1/4 or more)

CAUTION

When the fuel gauge indicates 1/4 or more, the fuel level is higher than the installation surface of the

fuel pump and the fuel suction pipe bracket. Due to this condition, fuel may spill or leak out when

performing next steps. Therefore, make sure to drain out fuel until the fuel tank becomes 1/4 full or less

(according to the fuel gauge indication).

WARNING

A person charged with static electricity could cause a fire or explosion, resulting in death or serious

injury. Before draining fuel, make sure to discharge static electricity by touching the vehicle body.

1) Disconnect the quick release connector (engine

compartment side).

2) Attach a long hose to the disconnected fuel pipe and drain the fuel into a proper receptacle.

3) Ground the check connector terminal F/P to the body using a jumper wire.

Page 4 of 18

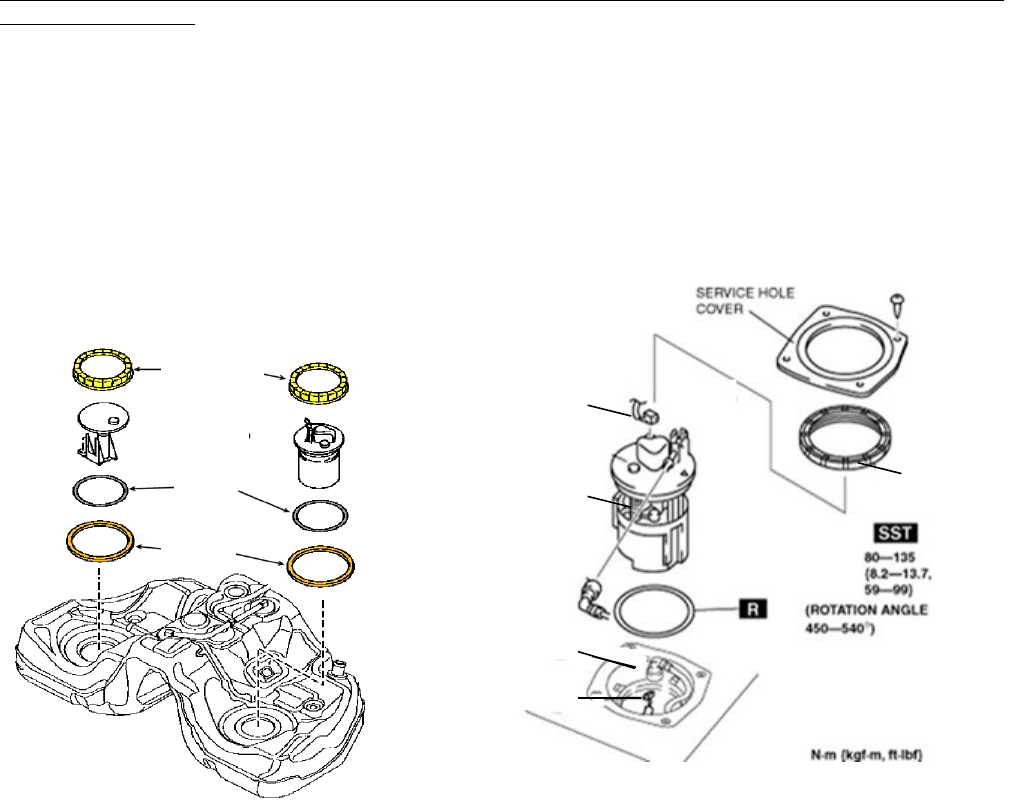

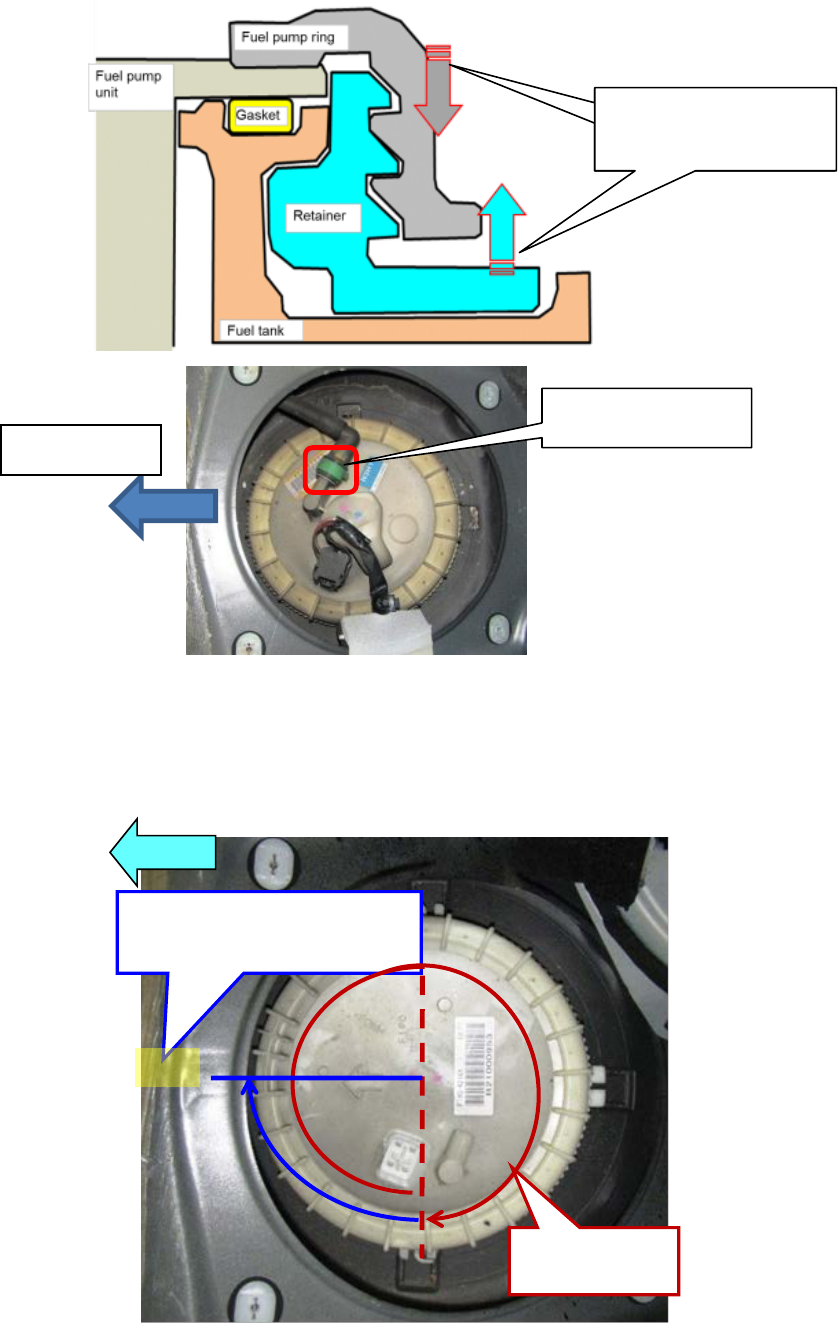

Fuel Pump

Ring

Fuel Pump

Unit (Main)

Fuel suction

P

ipe Bracket

(Sub)

Gasket

Retainer

CAUTION

Shorting a wrong terminal of the check connector may cause electrical malfunctions. Make sure to short

only the specified terminal.

4) Turn the ignition switch to the ON position and operate the fuel pump.

CAUTION

The fuel pump may malfunction if it is operated without any fuel in the fuel tank (fuel pump idling).

Constantly monitor the amount of fuel being discharged and immediately stop operation of the pump

when essentially no fuel is being discharged.

5) When essentially no fuel is being discharged from the hose, turn the ignition switch to the LOCK

position.

NOTE

When operating the fuel pump with a full fuel tank, fuel discharge will become erratic after approximately

10 min, but will continue for approximately 10 min more (and barely any fuel will be discharged). At this

time the fuel gauge needle will be at the 1/4 position.

6) Disconnect the jumper wire.

6. Disconnect the negative battery cable.

7. Replace the inner parts of fuel pump (main side) and the fuel pump ring (both sides) with a modified one,

along with the gasket and retainer. NOTE: If Recall 0516J (Fuel Leak at Fuel Pump Rings) is closed, the

retainer and fuel pump ring will be reused.

CAUTION

DO NOT LEAVE THE FUEL TANK FOR A LONG TIME IN CONDITION THAT THE FUEL PUMP RING

IS NOT INSTALLED.

If the fuel tank is left for a long time without the fuel pump ring installed, the shape of the fuel tank where

the fuel pump ring is installed could be deformed by swelling, causing it difficult to install the fuel pump

ring.

Therefore, install a new one immediately after removing the old fuel pump ring. To complete the

replacement in a short time;

・Complete the replacement at one side first then proceed to other side.

・Put replacement parts near the vehicle before starting the replacement.

・When you remove the fuel pump ring to disassemble/assemble the fuel pump unit, immediately

reinstall it again temporary to the fuel tank side by rotating with hands (No need to use SST).

Connector

Fuel pump unit

Fuel Pump Ring

Connector

Fuel suction pipe

Page 5 of 18

【

Main side (Fuel pump unit side)

】

1) Disconnect the connectors.

2) Disconnect the quick connector. (Fuel hose)

3) Remove the fuel pump ring using SST (Fuel Pump Ring Wrench).

NOTE: Fit the groove of the SST into the rib of the fuel pump ring

CAUTION

・The fuel pump ring could be damaged if the SST is used with any play between the fuel pump ring and

the SST. Securely attach the SST so that there is no gap between the SST tabs and the side of the fuel

pump ring.

・The fuel suction pipe and harness might be damaged, if the fuel pump unit is lifted too much. Make

sure to lift the pump only a small amount.

・When removing the fuel pump ring, be careful not making the retainer lift up. Otherwise, they will rotate

together and the fuel pump ring will not be removed.

4) Remove the fuel pump unit assembly.

5) Disassembly/Assembly the fuel pump unit according to <FUEL

PUMP UNIT DISASSEMBLY/ASSEMBLY>

CAUTION

After removing the fuel pump ring, immediately reinstall it again

temporary to the fuel tank side by rotating with hands (No need to

use SST). This is to prevent deformation by swelling at installing

portion of fuel tank while disassembling/assembling the fuel pump

unit.

SST (Fuel Pump Ring Wrench)

Page 6 of 18

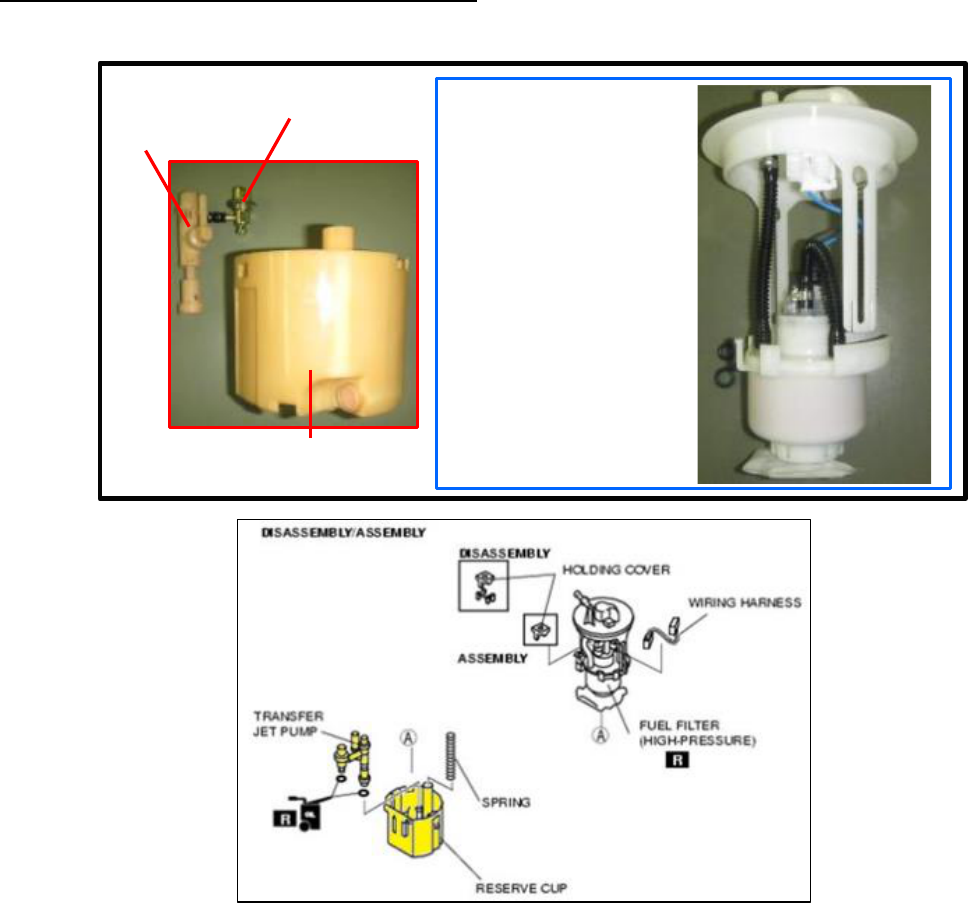

FUEL PUMP UNIT DISASSEMBLY/ASSEMBLY

Parts Information

Warning

Fuel line spills and leakage are dangerous. Fuel can ignite and cause serious injuries or death and

damage. Fuel can also irritate skin and eyes. To prevent this, do not damage the sealing surface of the

fuel pump unit when removing or installing.

Caution

Do not touch the fuel pump discharge pipe unless it is necessary. If servicing is needed, be careful not to

damage the pipe with tools or other objects, or by applying lateral stress. If the pipe is damaged, it may

cause fuel leakage or a fuel pump operation malfunction.

Be careful not to damage the pressure regulator or fuel hose. If it is damaged, it may cause fuel

leakage.

When any parts are removed, be careful that no foreign materials penetrate the part. Otherwise it may

cause a fuel pump unit operation malfunction.

Protect any removed parts using rubber matting to prevent damage. Furthermore, if a part has been

dropped, do not reuse it, replace it with a new one.

Do not use any textile products such as cotton work gloves. If used, fabric may get caught in the fuel

pump or pressure regulator causing a fuel pump unit operation malfunction.

Do not touch the flange seal side of the set plate. If it is damaged or foreign material adheres, it may

cause fuel leakage.

When removing foreign material inside the reserve cup, use fuel for flushing. If foreign material is

removed with air, it may penetrate into the jet pump pressure regulator.

REUSE

Wiring Harness

Fuel Filter

(High-pressure)

Holding cover

Fuel pump

O-ring

(Pressure regulator side)

Reserve cup

(Reuse)

Transfer

jet pump

(Reuse)

Pressure

regulator

(Reuse)

KIT COMPORNENT

REUSE

REUSE

O-ring

(Transfer jet pump side)

Page 7 of 18

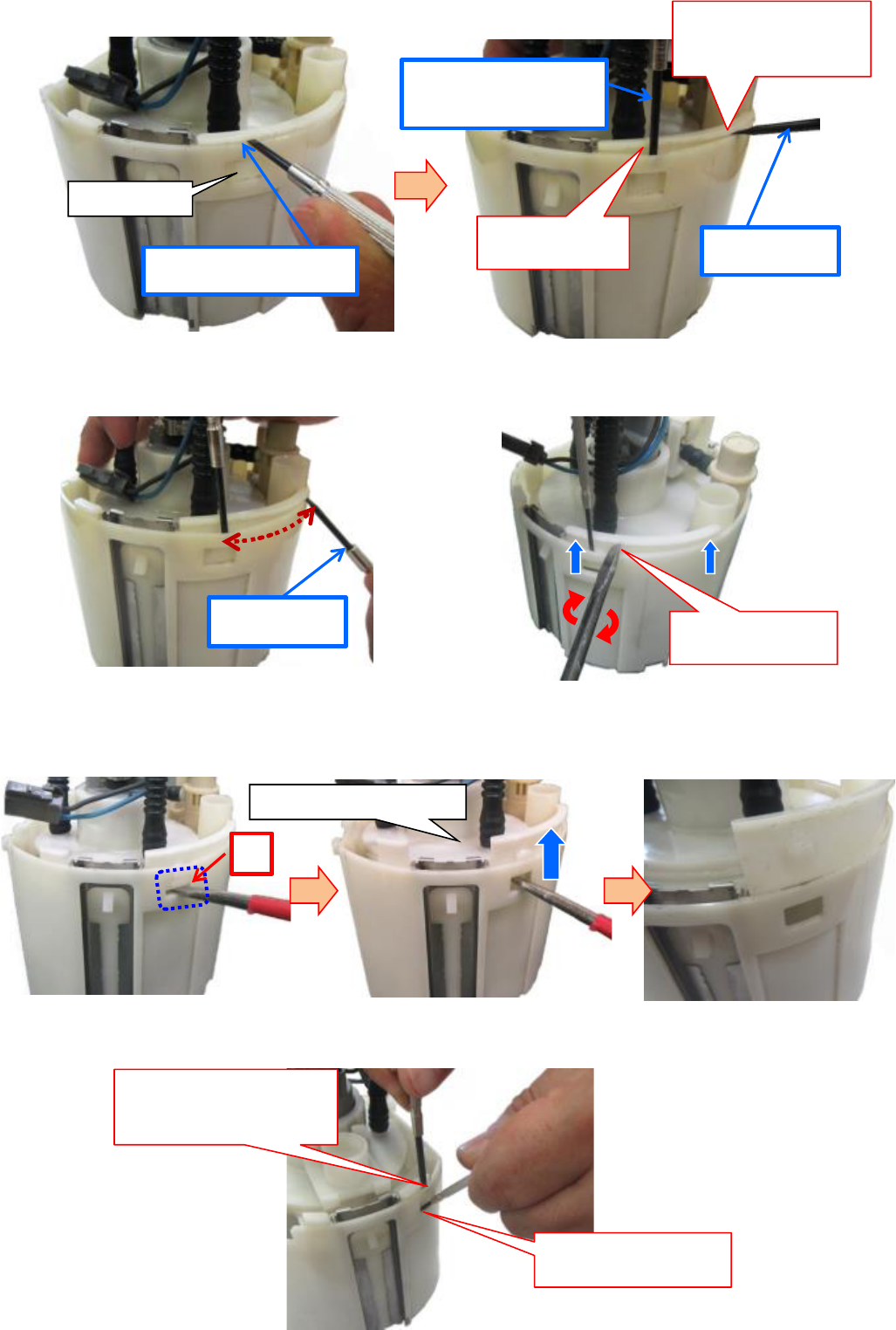

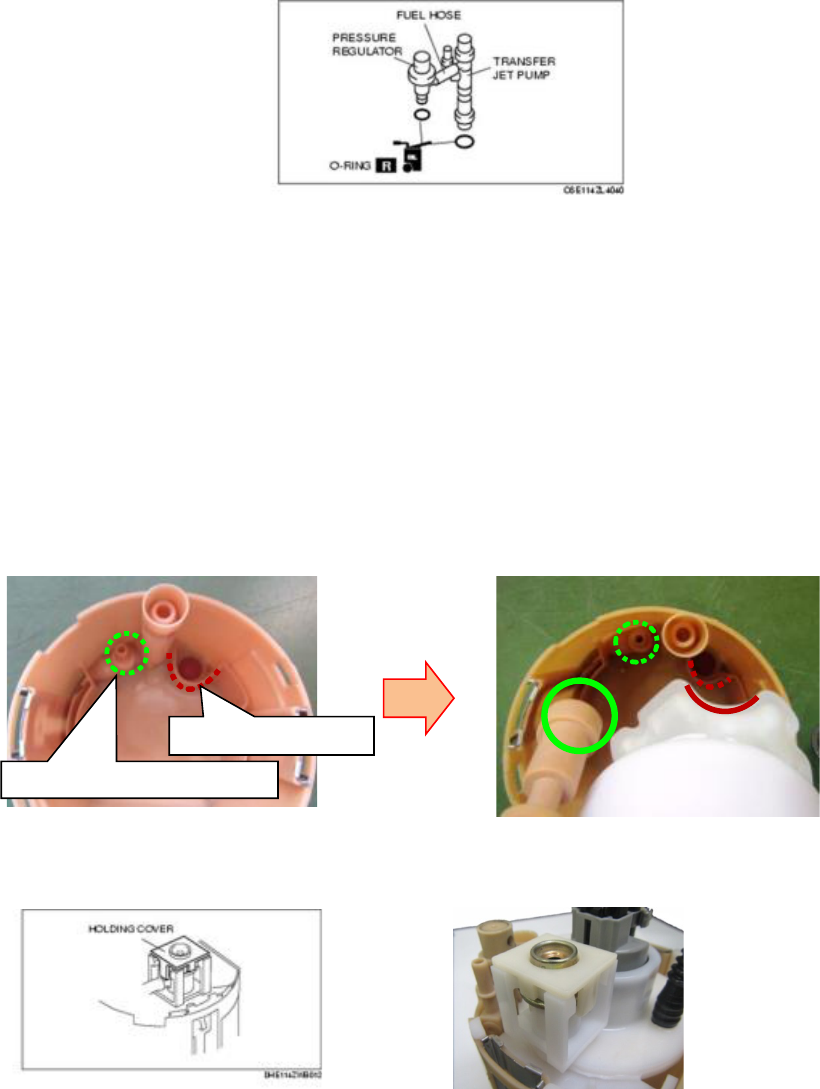

<DISASSEMBLY>

1. Remove the arm part of the set plate.

2. Disconnect the fuel pump connector.

3. Cut the nylon tube as shown below, then remove the set plate.

4. Remove the fuel pump, fuel filter, pressure regulator and

transfer jet pump as a single unit from the reserve cup while

pressing the snap fit tab using a flathead screwdriver.

CAUTION

When disengaging the snap fit tab, don’t hold the reserve cap

as shown below. This is to avoid injury when small flathead

screw driver slips and comes down unintentionally.

Nylon Tube

Set plate

Page 8 of 18

1) Insert the small flathead screwdriver (B) as shown below.

2) Pull up the fuel pump while disengaging the snap fit tab with small flathead screwdriver (A).

3) Insert the flathead screwdriver to clearance (A) as shown below, then pull up the fuel filter

(high-pressure).

4) In the same way as the other side, insert the small flathead screwdriver and pull up the fuel filter.

Rotate the flathead

screwdriver.

A

Snap Fit Tab

Insert the small flathead

screwdriver (B)

Widen the clearance

by using small

flathead screwdriver

Small flathead

screwdriver (A)

Disengage the snap fit

tab with small flathead

screw driver (B)

Disengage the

snap fit tab.

Small flathead

screwdriver (A)

Fuel filter (High-pressure)

Widen the clearance by

using small flathead

screwdriver (A).

Pull up the fuel pump

and filter.

Page 9 of 18

5) Remove the fuel filter (high-pressure), pressure regulator and transfer jet pump as a single unit

from the reserve cup.

NOTE: Verify that the reserve cup is not split, chipped, or bent.

<Reusability Judgment>

When the reserve cup is damaged, judge whether to reuse it depending on the damage condition.

【

Crack

】:

Reusable

【

Missing

】:

Not reusable

NOTE:

The following photo shows that fuel pump and filter are installed to reserve cup which has

cracked.

If the O-ring is remained on the reserve cup side,

remove the O-ring. (Discard the removed O-ring)

This is reusable because

s

nap fit tab is held by

reserve cup which has

crack.

Fuel filter

(high-pressure)

Transfer jet

pump

O-ring

Need to replace the fuel pump (N3H1-13-35ZG)

w ith new one.

Page 10 of 18

5. Cut the four legs located under the pressure regulator holding cover as shown below.

NOTE: Discard the removed pressure regulator holding cover.

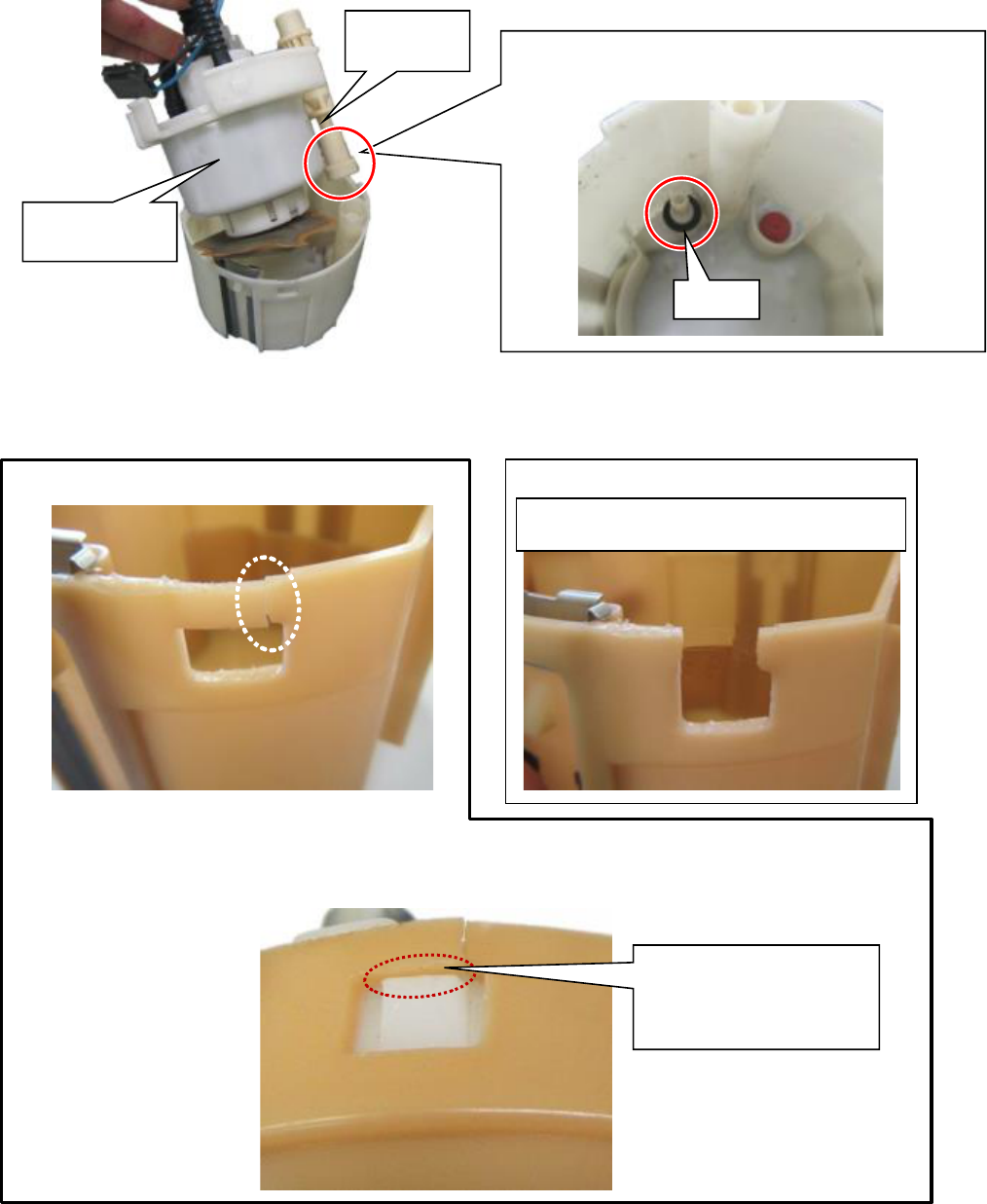

6.Remove the pressure regulator and transfer jet pump from the fuel filter (high-pressure) by using the

flathead screwdriver.

CAUTION

Do not pull out the fuel hose located between the pressure regulator and transfer jet pump. Do

not forcedly rotate or bend it, or it could damage the sealing of the fuel hose (press fit area), or

cause pipe breakage or splitting. In addition, if the fuel hose is buckled and fuel flow distortion

occurs, it may cause jet pump performance deterioration.

NOTE

Inserting the tip of the flathead screwdriver into the position indicated in the figure, rotate the

screwdriver to pry up the pressure regulator slightly.

7. Remove the O-rings from the transfer jet pump and pressure regulator.

Flathead screwdriver Transfer jet pump

Pressure regulator

Page 11 of 18

<ASSEMBLY>

CAUTION

Be careful not to damage the O-ring. If it is damaged, sealing damage might occur, causing fuel

leakage.

1. Apply clean engine oil to the new O-rings.

2. Install a new O-ring to the pressure regulator.

3. Install a new O-ring to the transfer jet pump.

CAUTION

Do not pull out the fuel hose between the pressure regulator and transfer jet pump. In addition, do not

forcibly rotate or bend it, or it may cause damage to the fuel hose sealing or pipe breakage/splitting. If

the fuel hose is buckled and fuel flow distortion occurs, it may cause jet pump performance

deterioration.

4. Install the transfer jet pump and pressure regulator to modified fuel filter (high-pressure).

5. Install the fuel filter (high-pressure), pressure regulator and transfer jet pump as a single unit to the

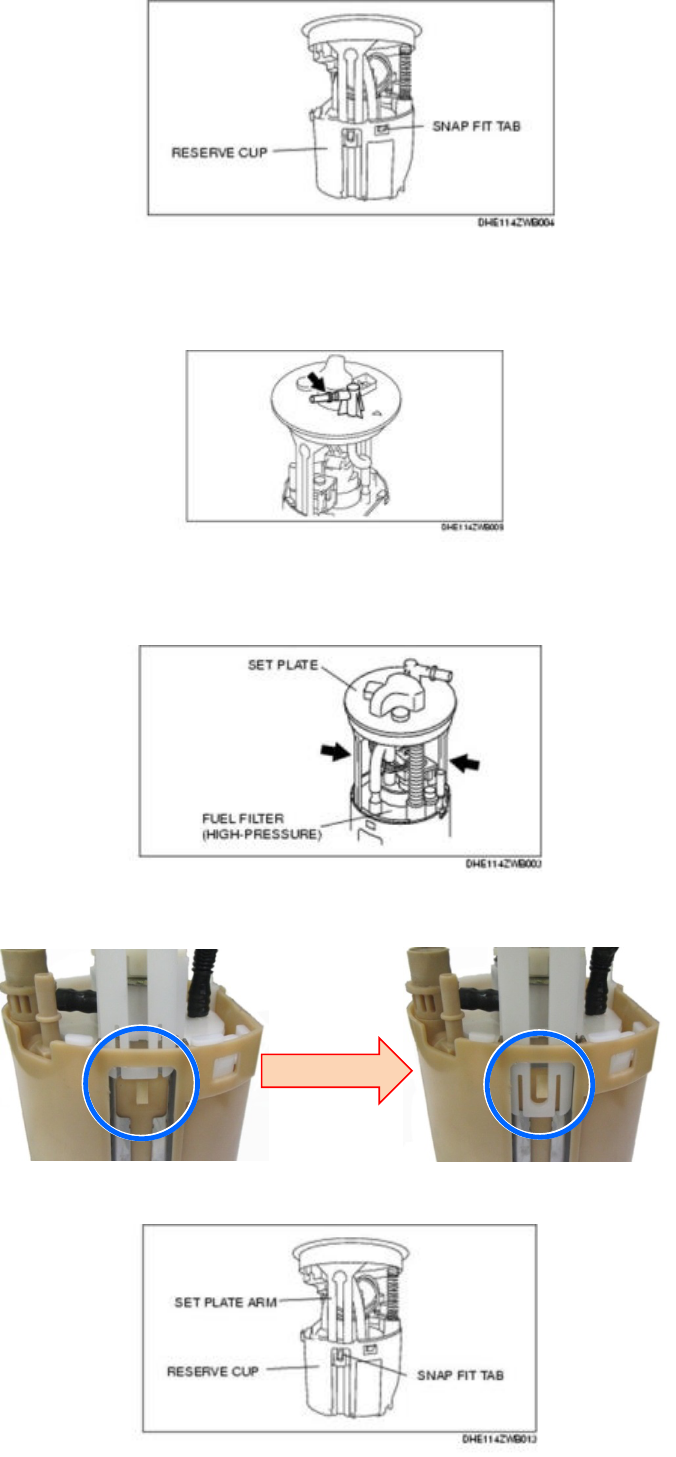

reserve cup.

6. Engage the snap fit tab and reserve cup, and verify that they are properly engaged.

7. Install the pressure regulator holding cover with new one and verify that the snap fit tab is properly

engaged.

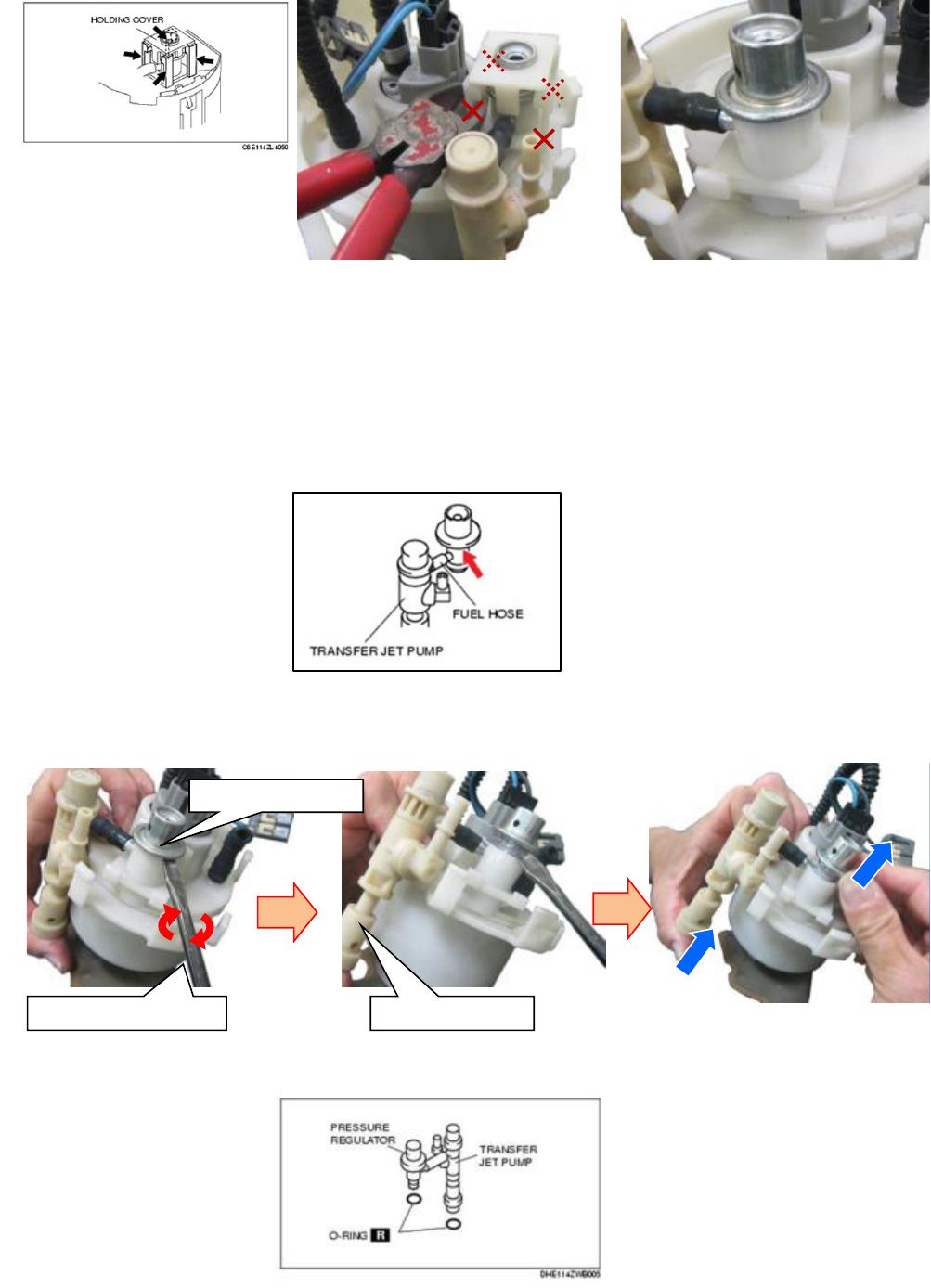

8. Perform the following procedure to install the set plate to the reserve cup.

NOTE: Reuse the spring by removing from old set plate.

Mounting of transfer jet pump

Mounting of fuel filter

Page 12 of 18

CAUTION

Do not grasp the pipe located on the upper surface of the set plate. The pipe may be damaged causing

fuel leakage.

CAUTION

Be careful not to break the set plate arm by applying excessive pressure. If it is broken, it may cause a

fuel pump unit operation malfunction.

1) Insert the set plate arm to the reserve cup.

2) Engage the snap fit tab and set plate arm, and verify that they are properly engaged.

Page 13 of 18

9. Route the wiring harness under the nylon tube.

10. Connect the fuel pump connector.

11. Press the set plate to expand/contract the fuel pump unit, and inspect it for the following:

The fuel pump connector wiring harness is not pinched into the pressure regulator holding cover.

12. Inspect the following and verify that each part is normal.

・Missing part

・Engagement condition of snap fit areas

・Splitting, chipping, bending, and cracking in each part

・Wiring harness routing

・Connector condition

Page 14 of 18

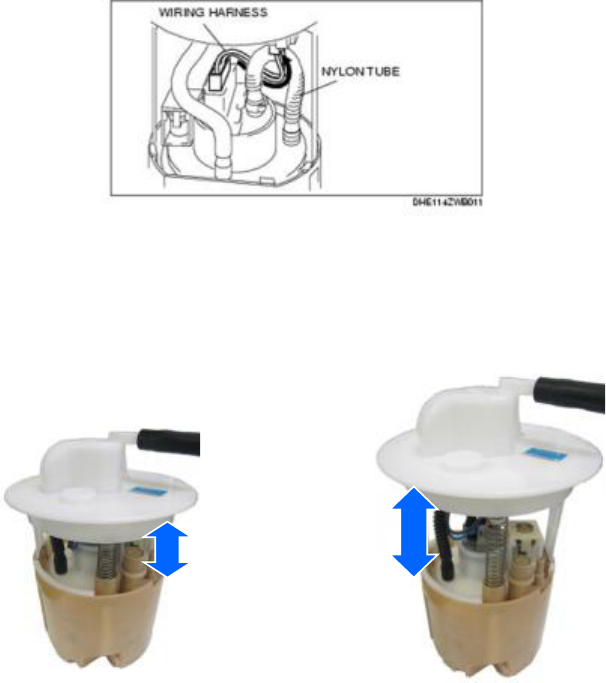

FUEL PUMP UNIT INSTALLATION

1. Replace the retainer and gasket with new ones.

NOTE: If Recall 0516J (Fuel Leak at Fuel Pump Rings) is closed, the retainer and fuel pump ring will be

reused.

CAUTION

Before installing the retainer, clean up the retainer fixing/installing portions of fuel tank (Sand or dust

might be accumulated).

2. Install the modified fuel pump ring.

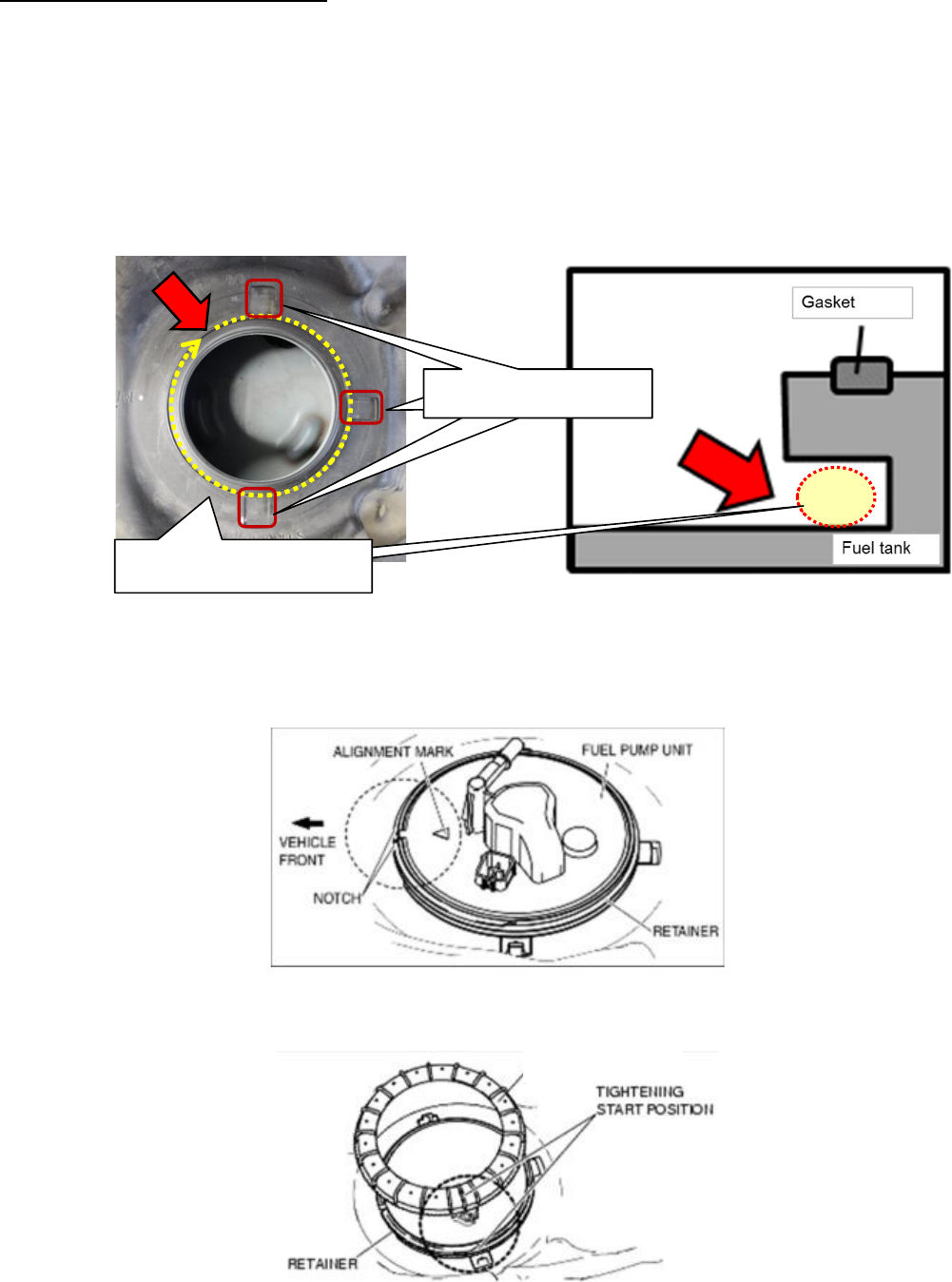

1) Align the fuel pump unit alignment mark and the retainer notch as shown in the figure.

2) Align the positions of the fuel pump ring and retainer as shown in the figure, and tighten them one full

rotation by hand.

NOTE

If the retainer and fuel pump ring cannot be tightened by hand, remove the fuel pump ring, verify that

there is no damage or misalignment on the retainer and fuel pump ring, and then tighten again.

Fuel Pump Ring

Clean 3 fixing portions

Clean all around the

installing portion.

Clean 3 fixing portions Clean 3 fixing portions

Page 15 of 18

CAUTION

・The fuel pump ring could be damaged if the SST is used with any play between the fuel pump ring and

the SST. Securely attach the SST so that there is no gap between the SST tabs and the side of the fuel

pump ring.

・When tightening the fuel pump ring, be careful not making the retainer lift up. If the retainer comes off

from fixing portions, the retainer spreads, the thread jams, and it reaches to specified torque before

rotating to specified position “☆”.

3. While keeping the alignment mark and the retainer notch aligned, tighten the fuel pump ring to the rotation

angle and specified torque using the SST.

Rotation angle 90-180° 【Total angle for Step 2) and Step 3) is 450-540°】

Fuel pump ring tightening torque 80-135 N· m {8.2-13.7 kgf·m, 59-99 ft·lbf}

One full rotation

by hand

Tighten so the Start position (3

ribs) comes

to mark ”☆” using

SST.

“☆”

Photo is Sub side

Front

When tightening the fuel

pump ring, the retainer

will be lifted up.

Vehicle Front

This fixing portion will

be easy to lift up.

Page 16 of 18

[Sub side]

① Disconnect the connector.

② Remove the fuel pump ring using SST (Fuel

Pump Ring Wrench)

③ Replace the retainer and gasket with new ones.

④ Install the modified fuel pump ring with the same

procedure as the main side.

4. Perform “Fuel Leak Inspection” after the fuel pump unit Installation

1) Start driving the vehicle from a standstill or brake suddenly 5-6 times at a low speed.

2) Stop the vehicle and verify from inside the vehicle that there is no fuel leakage around the fuel pump

ring and quick connector.

NOTE: If Recall 0516J (Fuel Leak at Fuel Pump Rings) is closed, skip the next step 1 (heat insulation

pads installation), and proceed to the step 2.

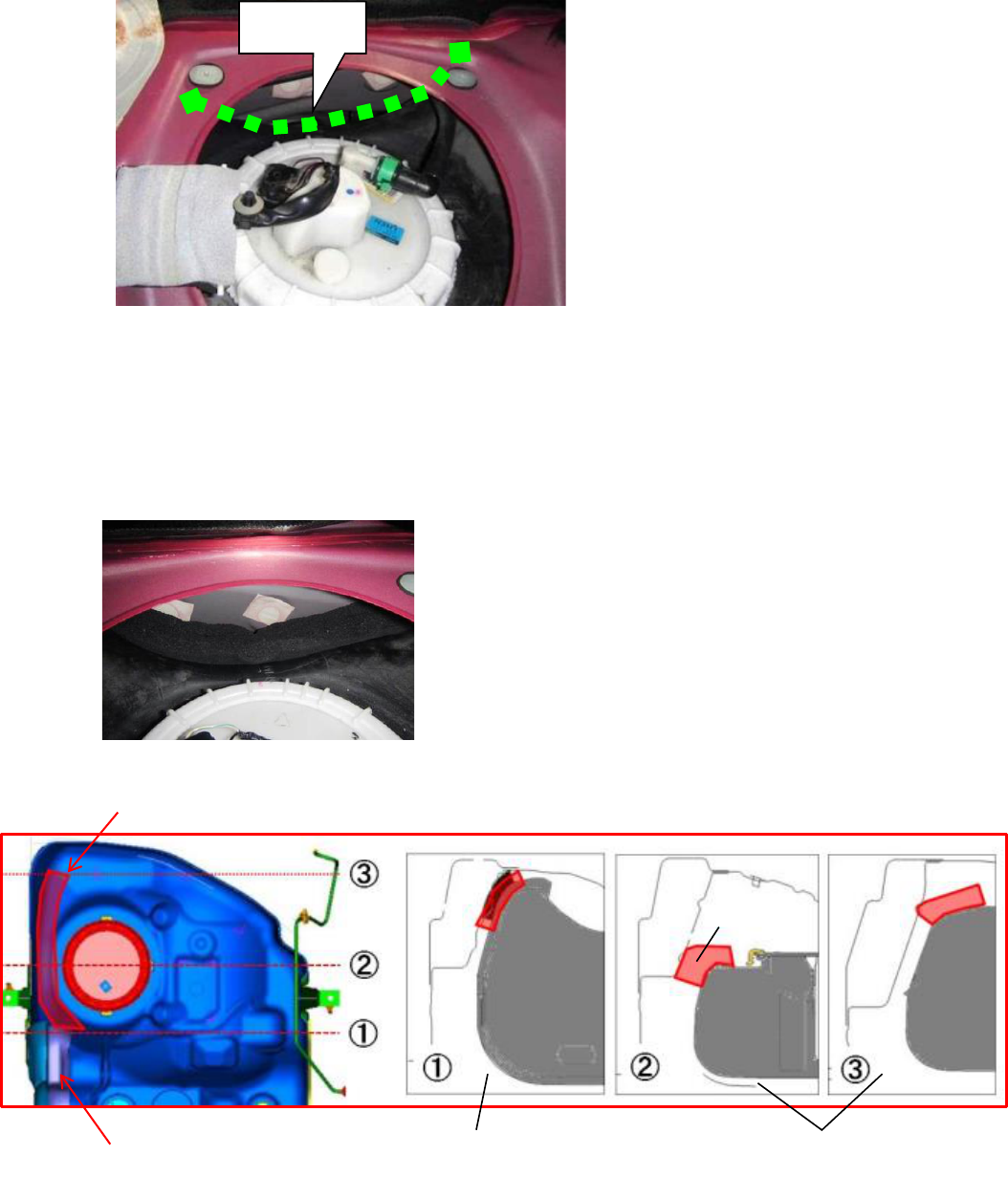

HEAT INSULATION PADS INSTALLATION

1. Attach two heat insulation pads to the fuel tank.

Confirm that there is no

fuel leakage all around the

fuel pump ring.

Confirm that there is no

fuel leakage around the

quick connector.

Heat Insulation Pad

Backing Tape

Pad

:300×60×30 (mm)

Existing Pad

New pads

Page 17 of 18

① Clean the fuel tank where the pad will be attached.

② Remove the backing tape and attach the pad to the fuel tank as shown below.

NOTE

• Attach the pad so it connects without clearance to the existing pad in the central portion of the

fuel tank.

Paste the pad onto the tank without clearance between the body and the tank.

After pasting the pads, confirm that the tape is stuck securely.

【Image how to paste the pads】

③ Attach the pad on the sub side repeating Steps ① - ②.

2. Install the service hole cover with four (4) screws.

3. Install the rear seat cushion.

Cleaning

Existing Pad

New pads

Paste pad without clearance to the

existing pad in the central portion

Paste pad without clearance

between body and fuel tank.

Fuel tank

Body

Pad

Page 18 of 18

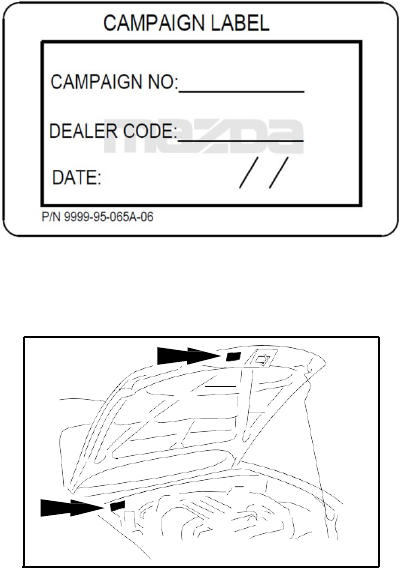

C. CAMPAIGN LABEL INSTALLATION

1. Fill out a blue “Campaign Label” (9999-95-065A-06) with Campaign No: “1017E”, your dealer code,

today’s

date.

2. Affix it to the hood or bulkhead as shown:

campaign_label

3. Return the vehicle to customer.