FUEL SERVICE TOOLS

66

Fuel Service Tools

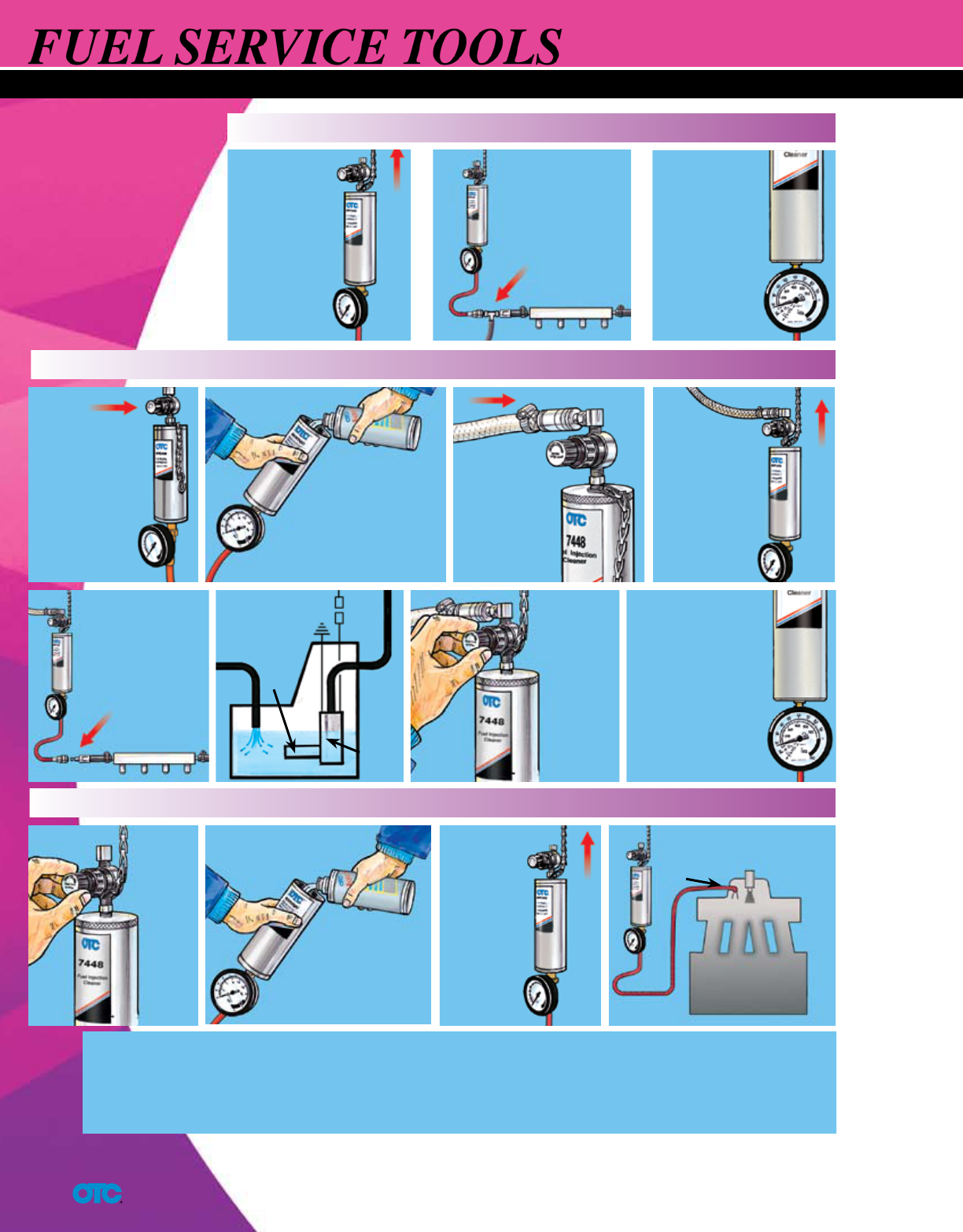

Diagnostic (Fuel Pressure Check)

Cleaning Injectors

Intake System Decarbonizing

Hang

container

under vehicle’s

hood on chain

provided.

1

Connect

cleaner

container

hose to

fuel rail.

2

Start engine

and check

gauge for

pressure

reading,

comparing

it to vehicle

specs.

3

Fully open

air regulator.

TURN

COUNTER-

CLOCKWISE.

1

Unscrew top of

container and pour in

16 ounces of No. 7000A

Pro Inject-R Kleen.

Replace container

top securely.

2

Connect

shop air

supply.

3

Hang

container

under hood

of vehicle

on chain

provided.

4

Unplugged

Fuel

Pump

Filter

Disable

fuel pump.

Connect

No. 7448

to inlet of

fuel rail.

Fuel Rail

5

6

Close

air

regulator

slowly.

TURN

CLOCK-

WISE.

7

Adjust pressure

regulator to 5 psi

under normal system

pressure. (This

prevents cleaning

fluid from backing

up into fuel tank

through pressure

regulator and fuel

return line.)

Start engine.

8

a) Locate a manifold vacuum port (NOT ported vacuum) near throttle body or carburetor to distribute decarbonizing solution

evenly. Connect decarbonizer hose with adapter to vacuum port.

b) Start engine. Manually increase throttle to 1,500 RPM. Slowly open shut-off valve until engine runs rough and RPM

decreases. (Do not manually increase RPM at this point.)

c) When 16 oz. of decarbonizer solution has been used, turn off engine. Remove adapter fitting from engine and reconnect

vacuum hose. Do not start engine for at least 30 minutes, to allow cleaning solution to loosen carbon deposits.

Fully

open air

regulator

by turning

counter-

clock-

wise.

1

Hang

container

under

vehicle’s

hood on

chain

provided.

3

Unscrew top

of container and

pour in 16 oz. of OTC

No. 7904A D-Karbonizer

4

.

2

4

Connect canister hose to

No. 7666 adapter fitting.

Intake Manifold

Engine

Throttle

Body

Manifold Vacuum

Port

5

Only

OTC offers

you complete

fuel injection

service

coverage:

FUEL SERVICE TOOLS

67

Fuel Service Tools

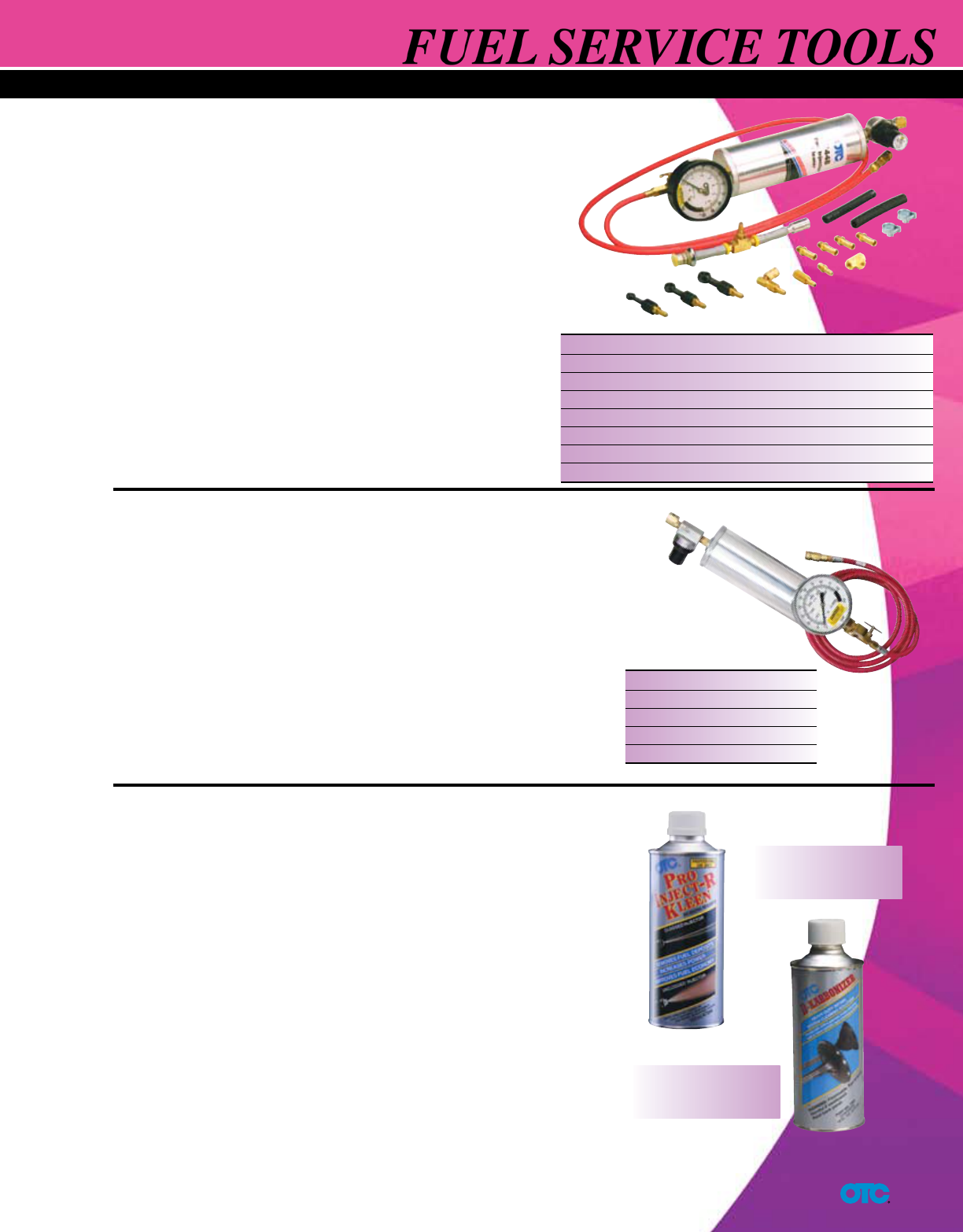

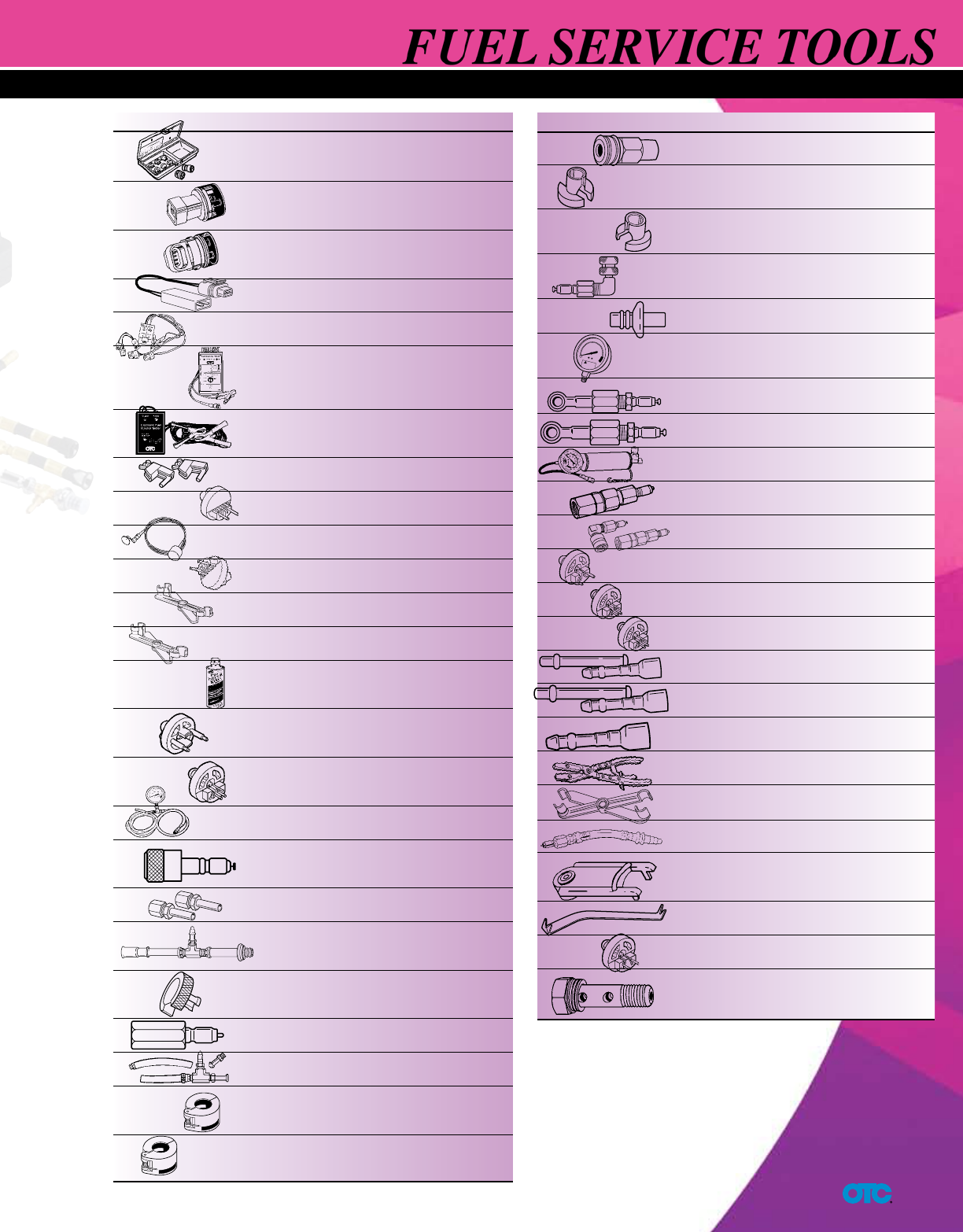

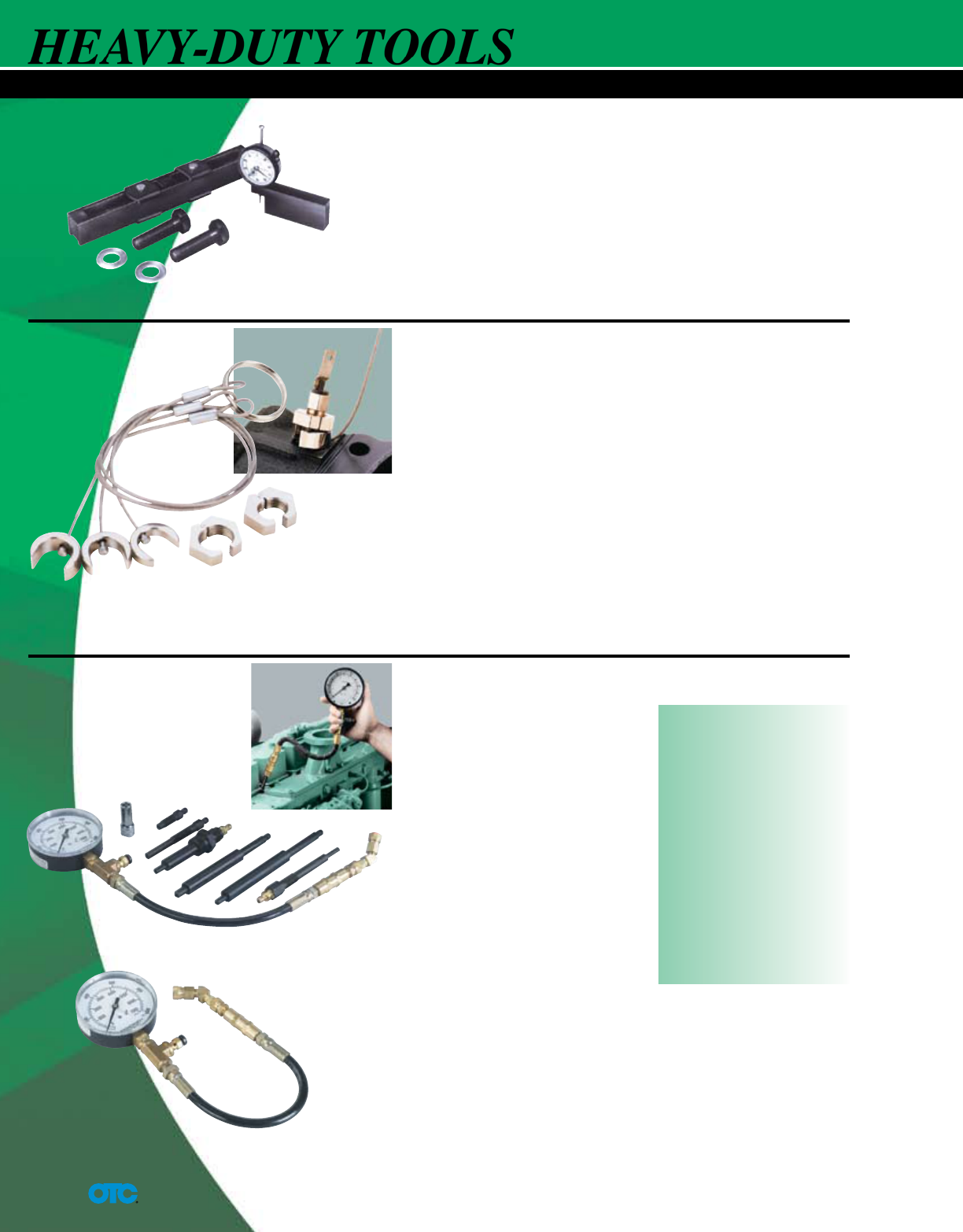

Fuel Injector Cleaning Kit

Clogged fuel injectors cause sluggish engine performance, poor

fuel economy, and a rough idle. You can easily correct such

problems with this injector cleaning kit. It works on a wide range

of engines, both domestic and imported. Using

our Pro Inject-R

Kleen fluid, you can effectively clean injectors,

restore their spray

patterns, and prevent recurring deposits. The kit also enables

you to do low- and high-pressure fuel

system tests. It will also

work with your shop’s pressurized air

supply for more powerful

cleaning without expensive propellants.

• Removes carbon from intake and combustion

systems when used with fitting No. 7666 and

No. 7904A D-Karbonizer

4

fluid.

• Includes canister, gauge, hose, fittings, operating

instructions.

No. 7649 – Fuel injector cleaning kit. Wt., 9 lbs., 10 oz.

No. 7659 – Fuel injector cleaning kit. Includes everything

in kit No. 7649, plus twelve 16 oz. cans of Pro Inject-R Kleen

fluid. Wt., 29 lbs.

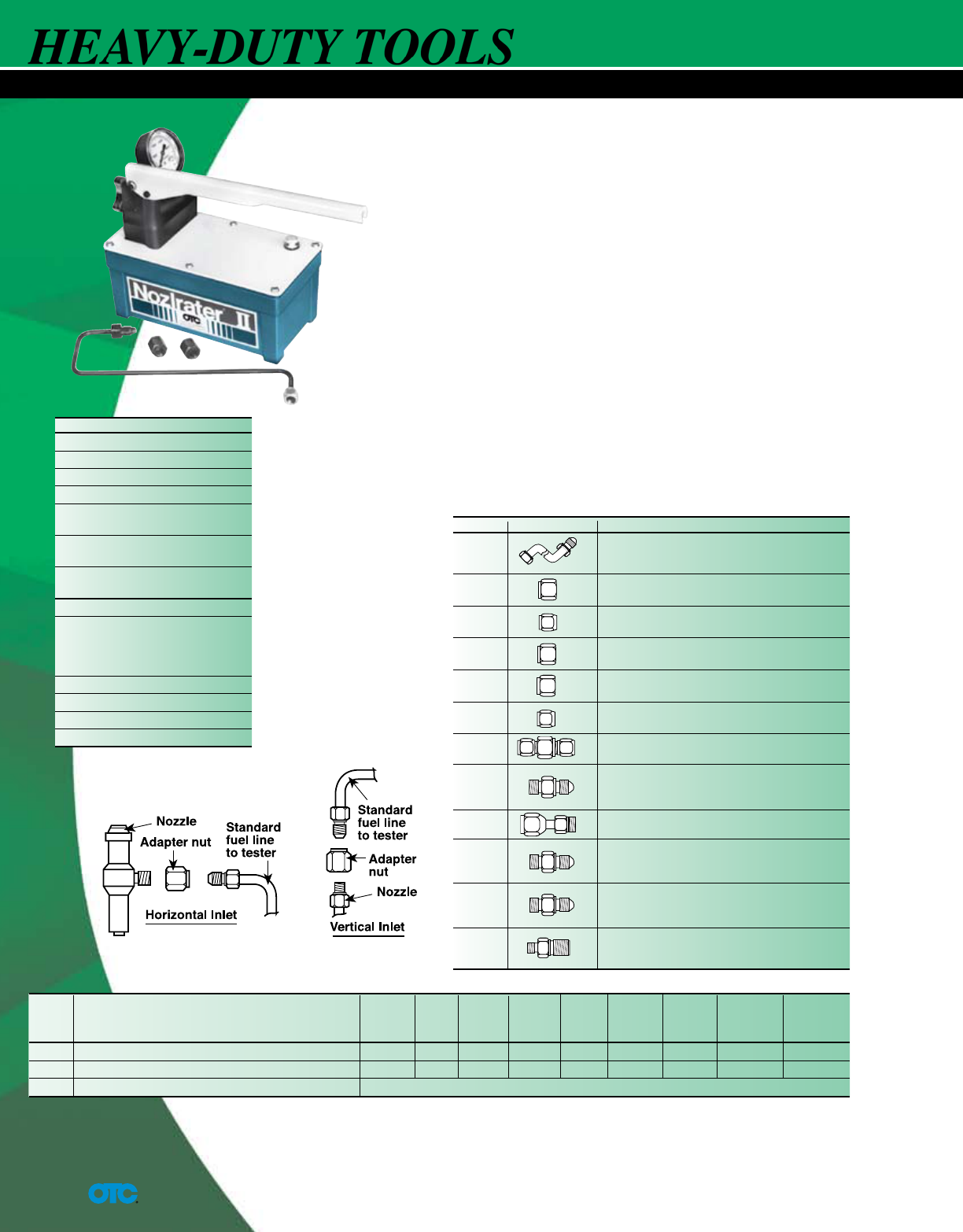

Canister-type Fuel Injector Cleaner

When connected to your shop’s pressurized air supply, this tool

provides the most effective method of cleaning fouled fuel injectors.

It’s much quicker than aerosol methods, and it works on many

domestic and imported engines, with either low- or high-pressure

systems. The canister, built with brass and aluminum, is rugged and

holds 18 fluid ounces. The gauge’s large dial is easy to read. We

recommend that our No. 7000A Pro Inject-R Kleen fluid be used with

this cleaner.

• Works with all OTC fuel injection system adapters.

• Will remove carbon from intake and combustion systems, when

used with our No. 7666 adapter and No. 7904A D-Karbonizer

4

fluid.

• Includes gauge, 72" hose, under-hood hanger, and instructions.

No. 7448

– Canister-type fuel injector cleaner. Wt., 6 lbs., 14 oz.

No. 7236 – Spring lock coupling adapter

No. 7272 – EFI quick-disconnect fitting (.307-32 internal; Ford)

No. 7273 – Pressure adapter TBI (5/16" and 3/8")

No. 7430 – Quick-disconnect 90° elbow fitting (7/16"–20 internal)

No. 7441 – Banjo fitting (M8 internal banjo)

No. 7442 – Banjo fitting (M10 internal banjo)

No. 7443 – Banjo fitting (M12 internal banjo)

No. 47955 – Fuel injector cleaner (canister)

7649

7448

Pro Inject-R Kleen Fluid

Clean fuel injectors mean cleaner running, more efficient engines – and

lower emissions. This fluid restores injectors’ original spray pattern,

helps prevent recurring problems, and reduces intake and port

deposits. We recommend it for all of our canister-type cleaning devices.

• No mixing; use right from the can.

No. 7000A – Pro Inject-R Kleen fluid. Case of 12 16-oz. cans.

Wt., 13 lbs., 10 oz.

No. 7000A-1 – Pro Inject-R Kleen fluid single can.

D-Karbonizer

4

Intake System Cleaning

When you need serious intake system cleaning, you need our

D-Karbonize

r

4

fluid. It quickly strips away carbon, gum, and varnish.

A clean intake and combustion system results in easier starting,

less engine knocking, better fuel economy, and fewer emissions.

We recommend it for all of our canister-type cleaning devices.

• No mixing; use right from the can.

No. 7904A – D-Karbonizer

4

intake system cleaning treatment.

Case of 12 16-oz. cans. Wt., 13 lbs., 10 oz.

No. 7904A-1 – D-Karbonizer

4

single can.

Not a fuel additive

DO NOT POUR INTO

FUEL TANK.

Not a fuel additive

DO NOT POUR INTO

FUEL TANK

.

7000A

7904A

No. 313575 – Pressure gauge

No. 213299 – Air regulator

No. 213209 – O-ring

No. 206878 – Coupler socket

No. 306905 – Hose

FUEL SERVICE TOOLS

68

Fuel Service Tools

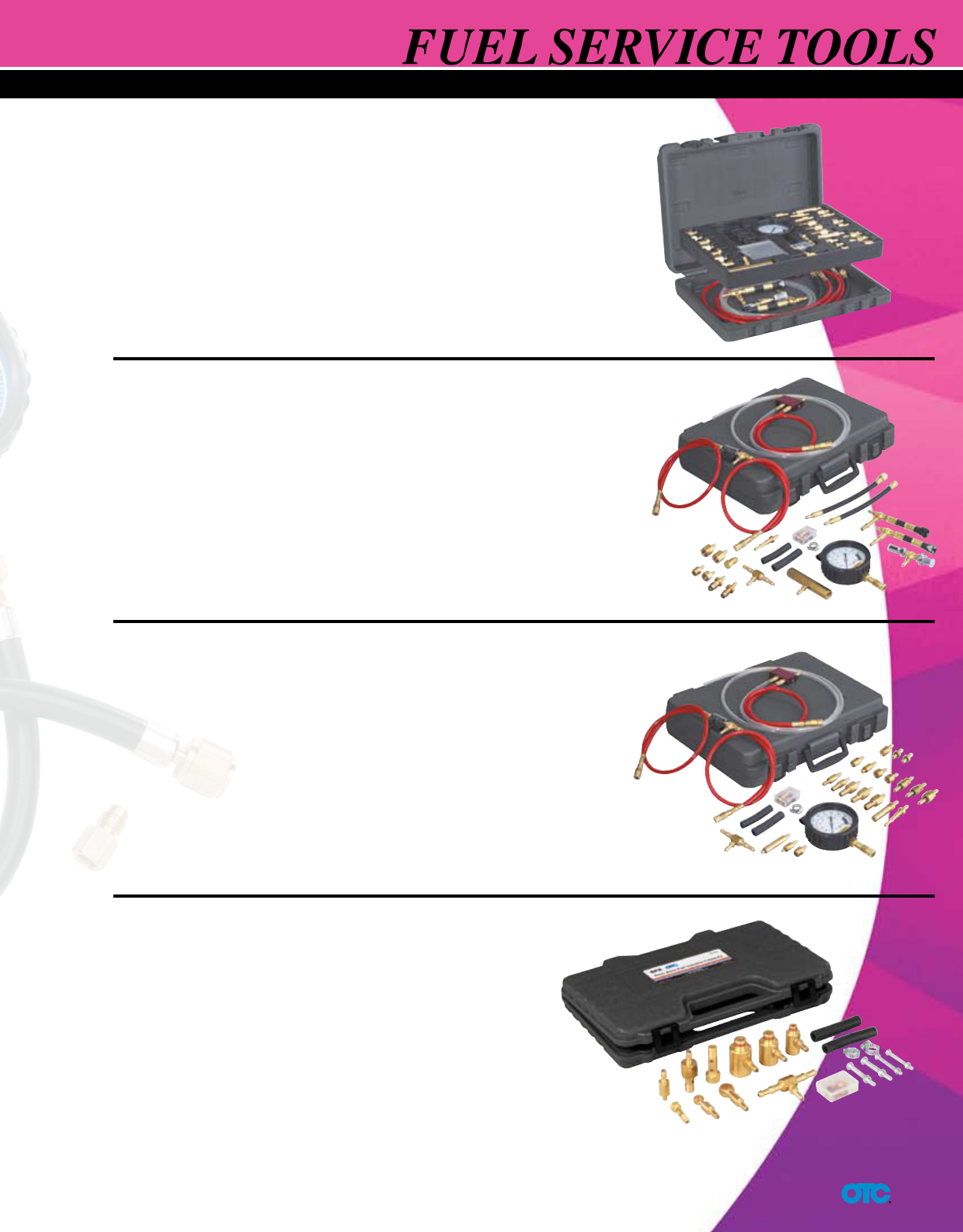

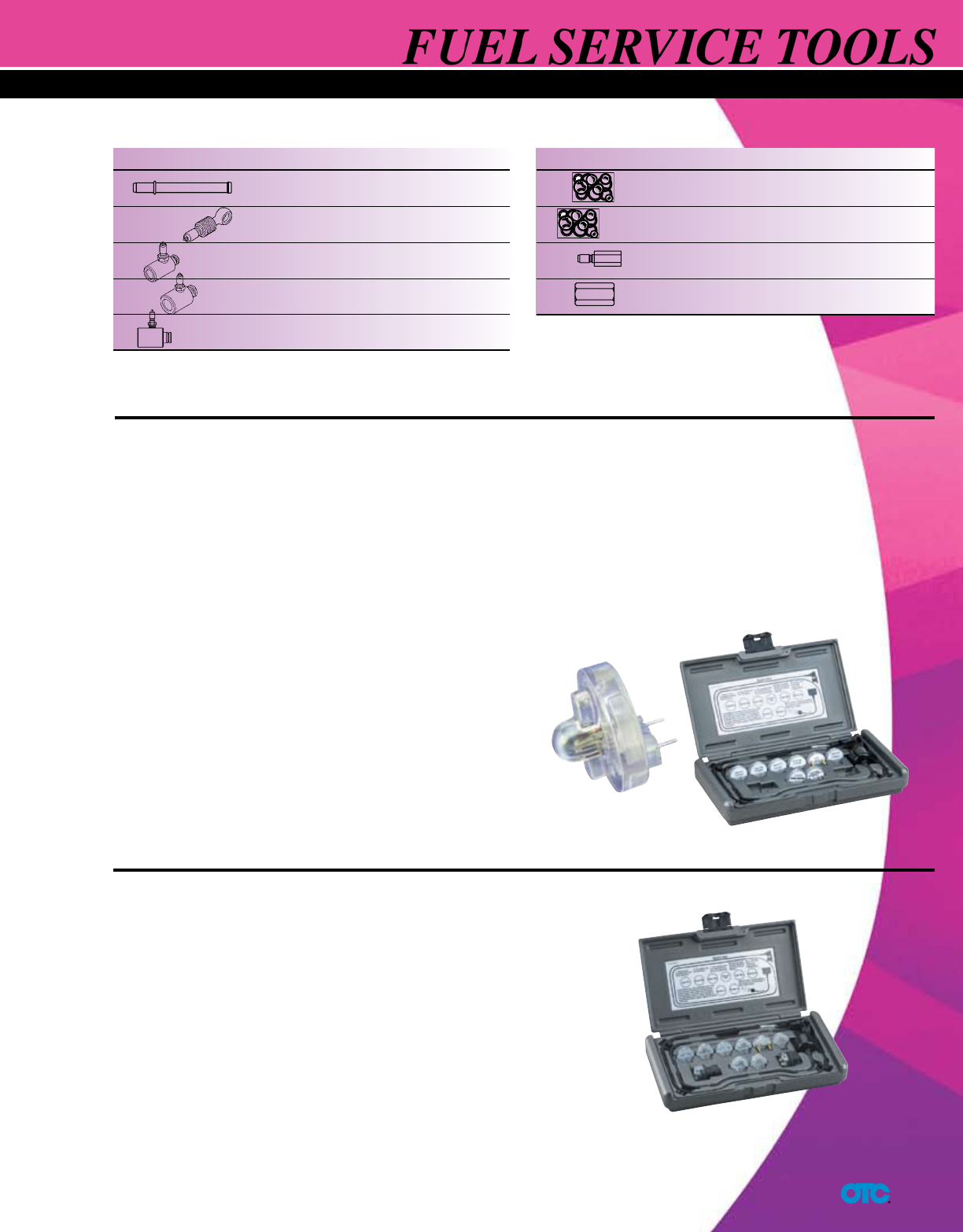

Fuel Injection Diagnostic Set

With these sets, you can quickly and accurately diagnose fuel

pressure problems on Chrysler, Ford, GM, or Jeep engines that

have multi-port fuel injection systems. You can also bleed air

from the system with the bleed valve. No. 7211 gauge assem-

bly allows technicians to check fuel pressure and fuel volume.

Set Includes:

No. 7665 – GM TBI fuel pressure adapter

No. 7430 – Quick-disconnect 90° elbow fitting

No. 7272 – Ford EFI quick-disconnect fitting

No. 211398 – Pressure hose

No. 206878 – Coupler

No. 19088 – O-ring

No. 7797 – Fuel injection diagnostic set. Wt., 1 lb., 13 oz.

No. 7635A – Basic fuel injection diagnostic set.

(Same as No. 7797, but does not include

No. 7665 GM TBI adapter.) Wt., 1 lb., 8 oz.

7797

7635A

Fuel Pressure Tester Kit

Quickly and easily locate any malfunctioning fuel system

component, including fuel filters, pressure regulators, fuel

lines, and fuel pumps without removing it from the vehicle.

Features and benefits:

• Large, easy-to-read 0–100 psi scale, 0–700 kPa.

• Solid brass fittings.

• Pressure relief valve for safe, clean testing.

No. 5630 – Fuel pressure tester kit. Wt., 1 lb., 4 oz.

7211

5630

Gauge and Hose Assembly

This gauge is designed to work with any of our fittings for

testing fuel injection systems. It features a sturdy 3-1/2" dial that

reads 0–100 psi. It also has a built-in (100–150 psi) retard to

prevent excess pressure damage. The assembly’s disconnect

fitting has a check valve to lessen chance of fuel spray.

• Includes 6-ft. bleed hose and 30" pressure hose.

• Bleed valve eliminates air from injection system and can be

used to reduce pressure when disconnecting hoses.

• Bleed valve also allows gauge assembly to be used to

check fuel pump volume.

No. 7211 – Gauge and hose assembly. Wt., 1 lb., 3 oz.

No. 306905 – Optional pressure hose, 70" long. Wt., 7 oz.

No. 7211M – Gauge, 6' bleed hose, and 70" pressure hose.

FUEL SERVICE TOOLS

69

Fuel Service Tools

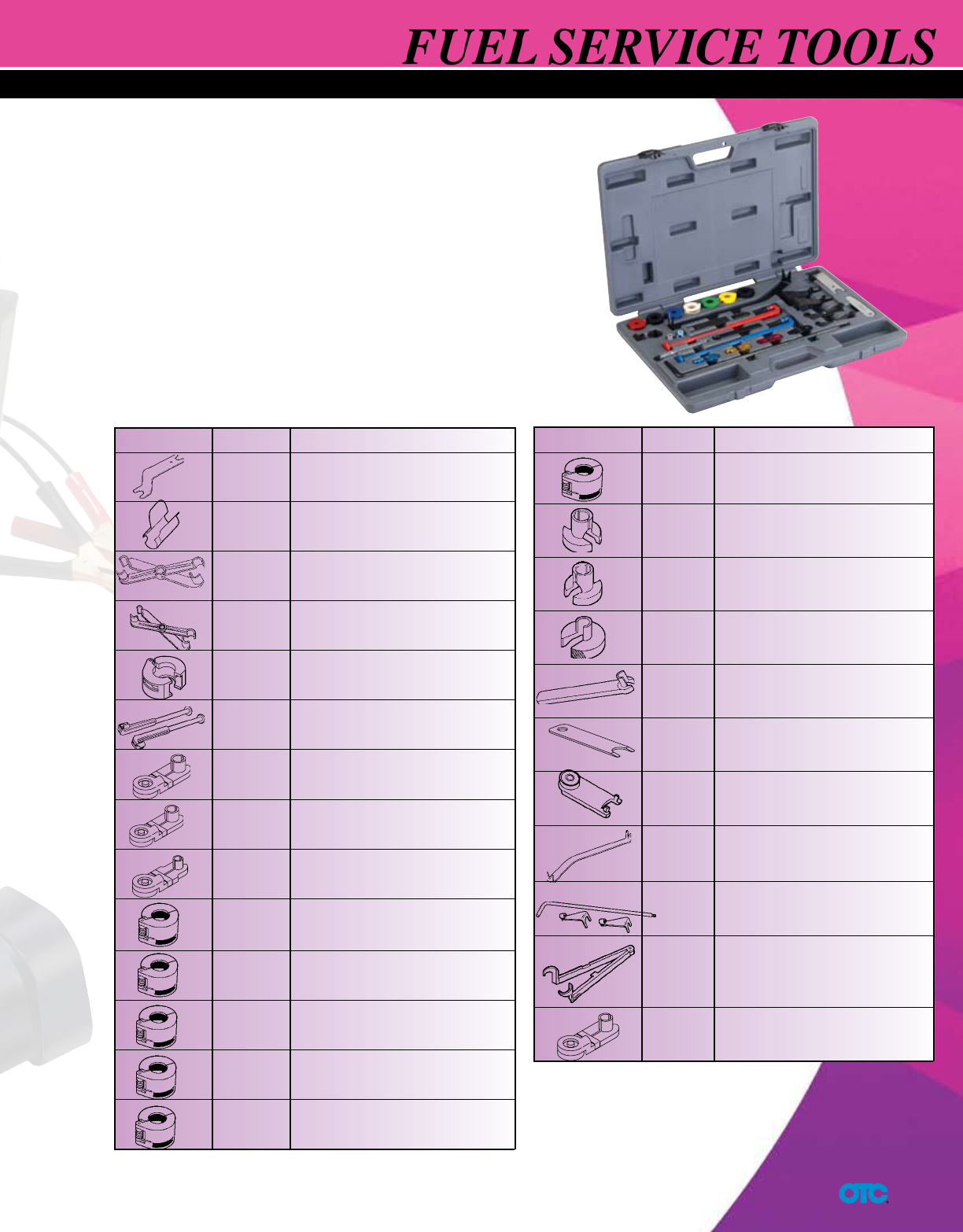

Master Fuel Injection Kit

Test fuel injection systems on most GMs, including GM TBI,

Ford, Chrysler, and Jeep vehicles. Also works on imports,

including CIS and CISE fuel systems. With this kit you can

diagnose fuel-related problems, such as a weak fuel pump or

restricted fuel filter, and perform leak-down tests. Kit includes

0–100 psi fuel pressure gauge and 35 of the popular OTC

fuel injection adapters, each equipped with a quick-connect

Schrader valve. Replacement seal kit also included.

No. 6550 – Master fuel injection kit. Wt., 11 lb., 12 oz.

Import Fuel Injection Kit

Test fuel injection systems on imports, including CIS and

CISE fuel systems. With this kit you can diagnose fuel-related

problems, such as a weak fuel pump or restricted fuel filter, and

perform leak-down tests. Kit includes 0–100 psi fuel pressure

gauge and 23 of the popular OTC fuel injection adapters, each

equipped with a quick-connect Schrader valve for. Replacement

seal kit also included.

No. 6552 – Import fuel injection kit. Wt., 4 lb., 2 oz.

Asian Fuel Injection Fitting Kit

The fittings in this kit enable you to connect OTC No. 7211 gauge

(not included) to most Hyundai, Honda, Mitsubishi, and other

Asian automotive engines, and diagnose most common fuel

system problems involving low fuel pressure and low fuel

volume at the

injectors. Each fitting comes with a quick-connect

Schrader

valve for easy hookup to the gauge assembly.

• Fitting seals are compatible with most popular cleaning solvents.

• Includes operating instructions and handy blow-molded case.

No. 6570 – Asian fuel injection fitting kit. Wt., 3 lb.

Domestic Fuel Injection Kit

Test fuel injection systems on most GMs, including GM TBI,

Ford, Chrysler, and Jeep vehicles. With this kit you can

diagnose fuel-related problems, such as a weak fuel pump

or restricted fuel filter, and perform leak-down tests. Kit

includes 0–100 psi fuel pressure gauge and 17 of the

popular OTC fuel injection adapters, each equipped with a

quick-connect Schrader valve. Replacement seal kit also

included.

No. 6551 – Domestic fuel injection kit. Wt., 4 lb., 2 oz.

6552

6570

6550

6551

FUEL SERVICE TOOLS

70

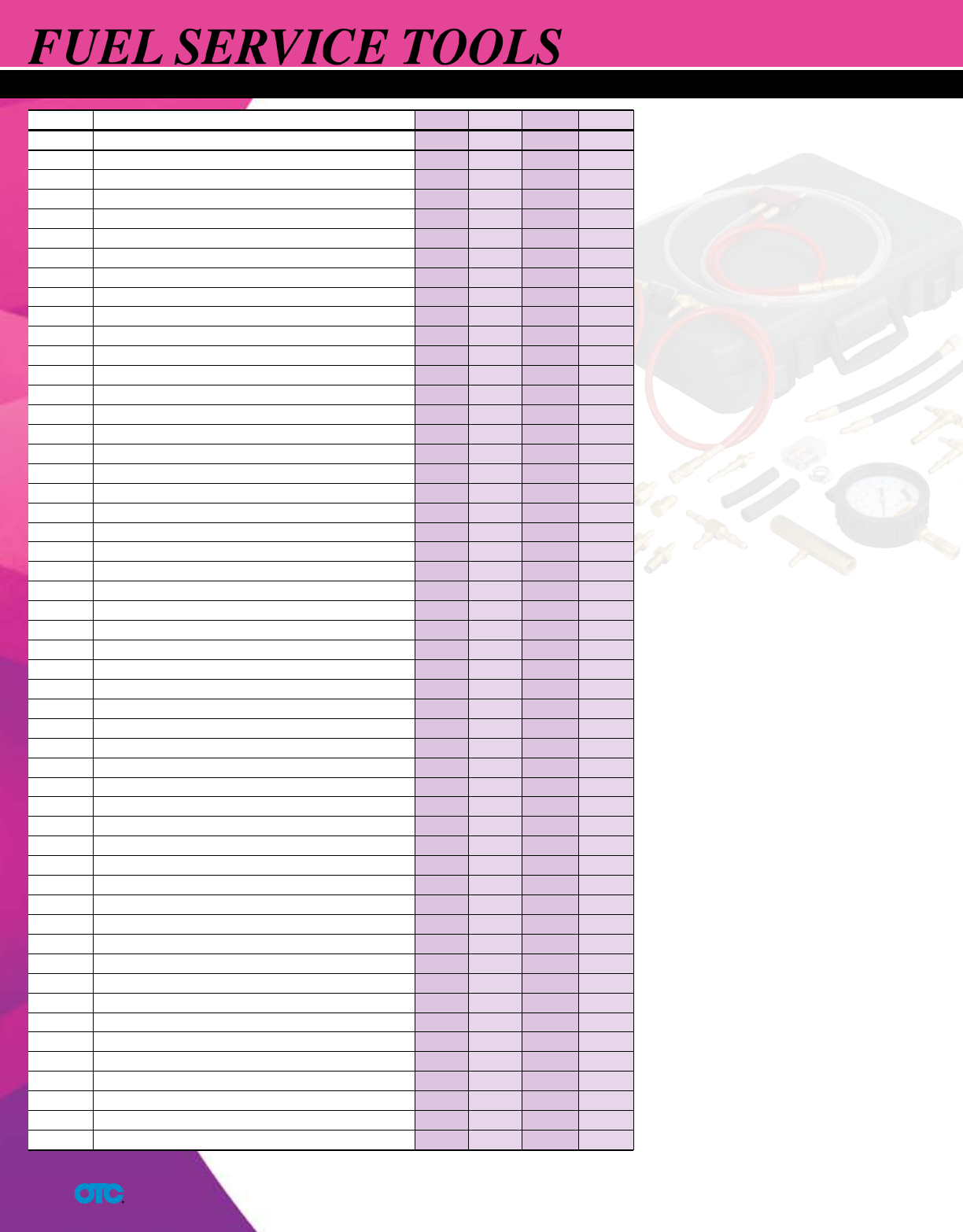

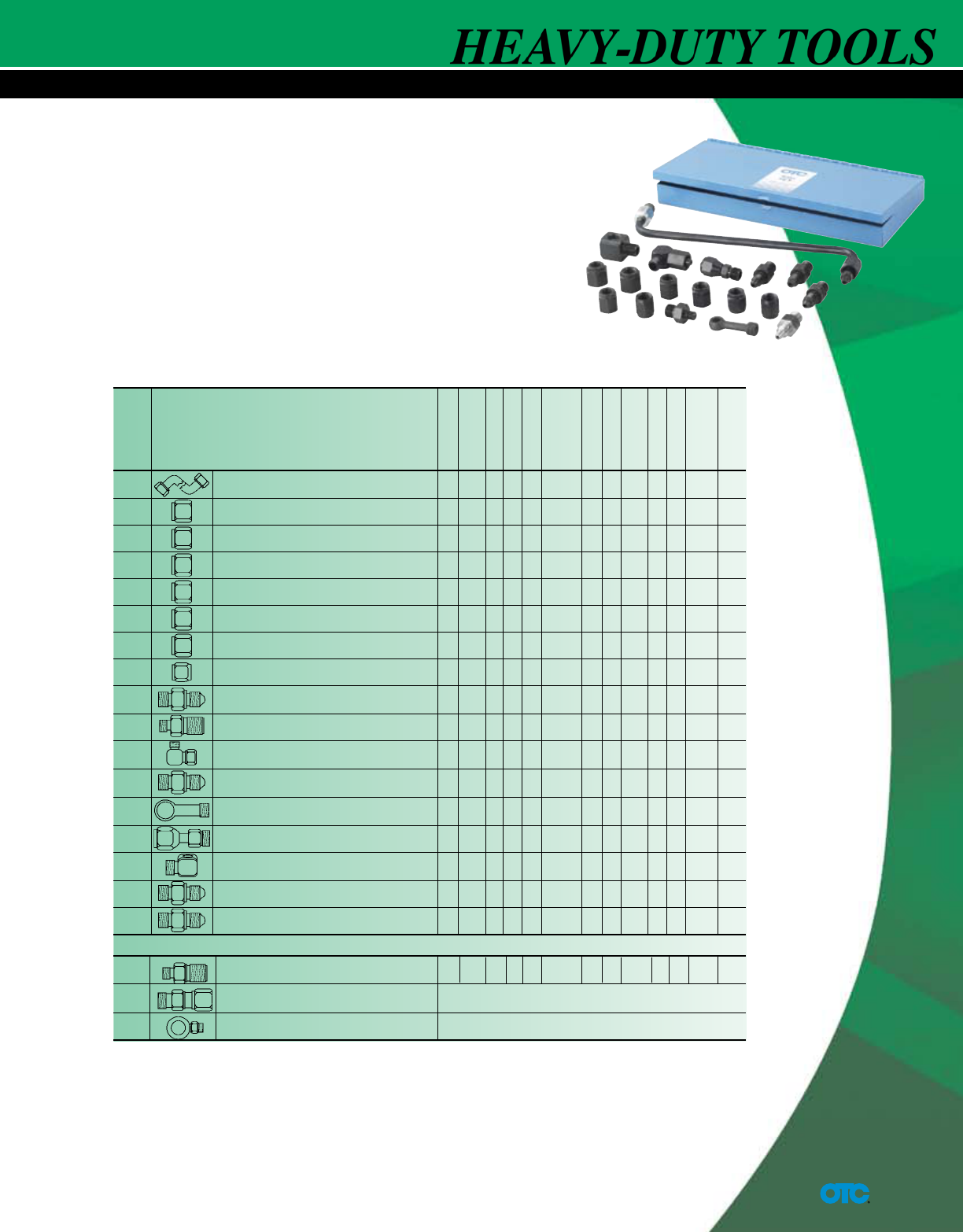

Fuel Injection Comparison Chart (Adapters, Fittings, and Accessories)

No. Description 6550 6551 6552 6570

518356 CIS/TBI hose assembly with shutoff valve

•

•

•

518472 16 mm x 1.5 internal o-ring adapter

•

•

518473 14 mm x 1.5 external o-ring adapter

•

•

518474 14 mm x 1.5 internal o-ring adapter

•

•

518476 Ford hairpin adapter (5/16")

•

•

518477 Seal Kit

•

•

•

518478 Single-end hose adapter (1/4, 5/16, 3/8)

•

•

•

518480 Double-end hose adapter (5/16, 3/8)

•

•

•

•

518481 16 mm x 1.5 external o-ring adapter

•

•

518482 14 mm x 1.5 external o-ring plug

•

•

518483 3-1/2" gauge, 0–100 psi (0–7 BAR)

•

•

•

518484 M10 x 1.0 internal o-ring adapter

•

•

518485 M8 x 1.0 internal o-ring adapter

•

•

518486 M12 x 1.5 internal swivel adapter

•

•

518487 GM TBI inline adapter (16 mm x 1.5)

•

•

518488 M8 x 1.0 external o-ring adapter (long)

•

•

518489 M10 x 1.0 external o-ring adapter

•

•

518490 M6 x 1.0 external o-ring adapter

•

•

•

518491 M8 x 1.0 external banjo adapter

•

•

518492 M10 x 1.0 external banjo adapter

•

•

518493 M12 x 1.5 external banjo adapter

•

•

518494 M12 x 1.25 external banjo adapter

•

•

•

518495 Ford flexible EFI adapter

•

•

518496 M16 x 1.5 external & internal swivel adapter

•

•

518497 1/4" BSPT external & internal swivel adapter

•

•

518498 M14 x 1.5 external & internal swivel adapter

•

•

518499 Ford spring lock adapter

•

•

518501 M14 x 1.5 external banjo adapter

•

•

518527 GM/Chrysler hairpin adapter (3/8")

•

•

518530 Gauge hose assembly with relief valve

•

•

•

518534 5/8" x 18 external flare adapter

•

•

518535 5/8" x 18 internal flare adapter

•

•

518536 M8 x 1.0 external o-ring adapter

•

•

518537 M8 x 1.0 internal o-ring adapter (long)

•

•

518542 7/16 x 20 GM/Chrysler flexible adapter

•

•

528177 7/16 x 20 GM/Chrysler elbow adapter

528178 7/16 x 20 GM/Chrysler straight adapter (short)

528180 Low pressure gauge 0–15 psi (0–1 BAR)

528182 16 mm x 1.5 elbow GM TBI fitting

528183 3/8 hairpin adapter

528541 5/8 x 18 flare straight adapter

528766 M12 banjo adapter

•

528767 M8 x 1.0 double banjo bolt

•

528768 M12 x 1.25 double banjo bolt

•

528769 M8 banjo fitting

•

528770 .430 diameter adapter

•

528771 .560 diameter adapter

•

528772 5/8" diameter adapter

•

528773 O-ring & washer kit

528774 O-ring & washer kit

•

528776 Ford EFI adapter

528779 16 mm x 1.5 internal union adapter

FUEL SERVICE TOOLS

71

Fuel Injection Comparison Chart (Adapters, Fittings, and Accessories)

Part No. Description

3054C Noid Lite/IAC signal tester with fiber

optic cable. Wt., 15 oz.

3052S IAC signal tester (GM).

(Square 4-pin connector). Wt., 3 oz.

See page 74.

3053S IAC signal tester (GM).

(Flat 4-pin connector). Wt., 3 oz.

See page 74.

3305-53

TBI adapter. Wt., 11 oz.

3320 2-in-1 idle air/ idle speed control tester

Wt., 10 oz. See page 49.

3397 Fuel injector tester (TBI adapter

included). (Same as Kent-Moore

J-39021-22.)

Wt., 2 lbs., 10 oz. See page 48.

3398 Fuel injection pulse tester.

Wt., 10 oz.

See page 74.

4506 Fuel line clamp set

Wt., 6 oz.

6023 Noid Lite (for GM Multec 2 injectors).

Wt., 2 oz. See page 73.

6260 Fiber Optic Noid Lite Extension Cable.

Wt., 5 oz. See page 74.

6266 Noid Lite (for GM Bosch 2 injectors).

Wt., 2 oz.

6509 Fuel line disconnect tool. Wt., 3 oz.

See page 76.

6511 Fuel line disconnect tool. Wt., 3 oz.

See page 76.

7000A Injector cleaning fluid. case of 12 cans.

Wt., 13 lb., 10 oz.

See page 67.

7187 Noid Lite (GM TBI).

GM model 220, 300, 500 series TBI.

Wt., 2 oz. See page 73.

7188 Noid Lite (Bosch PFI).

GM model 700 series TBI.

Wt., 2 oz. See page 73.

7211 Pressure gauge assembly

(0–100 psi). Wt., 1 lb., 3 oz.

7214A Quick-disconnect straight fitting (

7

⁄

16

–

20

internal). (Also conversion adapter

for

Champion and 3M.) Wt., 2 oz.

7222A Adapter set (5/8-18

internal

, 45º flare

inverted. Wt., 7 oz.

7236 Spring lock coupling adapter same

as Ford 310-D003

(D85L-9974-C). Wt., 7 oz.

7244 Quick-disconnect tool (for duck bill

clips). Same as Ford 307-123

(T82L-9500-AH). Wt., 2 oz.

7272 EFI Quick coupler disconnect fitting

(Ford .307-32 internal). Wt., 1 oz.

7273 Pressure adapter (

5

⁄

16

" &

3

⁄

8

" fuel line).

Wt., 8 oz.

7335 Fuel line disconnect tool (

3

⁄

8

") (yellow).

Same as Ford 310-D004

(D87L-9280-A). Wt., 2 oz.

7336 Fuel line disconnect tool (

1

⁄

2

") (green).

Same as Ford 310-D005

(D87L-9280-B.) Wt., 2 oz.

Part No. Description

7342 Quick coupler adapter.

Wt., 2 oz.

7370 Fuel line disconnect tool (

5

⁄

16

") (gray).

Same as Ford 310-040

(T90T-9550-B). Wt., 1 oz.

7371 Fuel line disconnect tool (

3

⁄

8

") (blue).

Same as Ford 310-041

(T90T-9550-C). Wt., 1 oz.

7430 Quick-disconnect 90° elbow fitting (

7

⁄

16

–

20

internal

). Also conversion adapter

for Champion & 3M. Wt., 3 oz.

7433 Fuel return line plug (

3

⁄

8

" external).

Wt., 2 oz.

7439 Pressure gauge (0–100 psi).

Has a built-in retard (100–150 psi).

Wt., 11 oz.

7442 Banjo fitting (M10

internal

banjo).

Wt., 3 oz.

7443 Banjo fitting (M12

internal

banjo).

Wt., 3 oz.

7448 Fuel injector canister-type cleaner.

Wt., 6 lbs., 13 oz. See page 67.

7472 Conversion adapter (M12 x 1.5

internal

ball nose snap-on). Wt., 3 oz.

7597 Conversion Adapter Kit (7430 & 7472

snap-on). Wt., 7 oz.

7601 Noid Lite (Ford TBI). Wt., 1 oz.

See page 73.

7602 Noid Lite (GM PFI). Wt., 1 oz.

See page 73.

7608 Noid Lite (Geo TBI). Wt., 1 oz.

See page 73.

7628 Special fitting set (5/16").

Wt., 3 oz.

7629 Special fitting set (3/8").

Wt., 3 oz.

7631 Fuel return line plug (5/16").

Wt., 2 oz.

7655 Pinch-off pliers.

Wt., 13 oz.

7660 Fuel line disconnect tool. Same as

Ford 310-052 (T93T-9550-AH).Wt., 2 oz.

7666 Decarbonizing adapter.

Wt., 5 oz.

519154

Ford fuel line coupling tool. Same as

310-052 (T90T-9550-A).

Wt., 1 oz. See page 77.

519155 Chrysler fuel line disconnect

Tool. Wt., 10 oz.

7828 GM SCPI Noid-Lite.

Wt., 2 oz. See page 73.

518501 EFI pressure test adapter

(M14 x 1.5 external double banjo).

Wt., 3 oz.

100

20

0

300

400

500

600

1000

0

0

10

2

0

30

40

5

0

60

7

0

8

0

90

100

CAUTI

O

N

N

o

s

m

o

k

i

n

g

,

o

p

e

n

f

l

a

m

e

e

t

c

.

F

l

a

m

m

a

b

l

e

m

i

x

t

u

r

e

p

r

e

s

e

n

t

.

P

o

s

s

i

b

l

e

h

u

m

a

n

i

n

j

u

r

y

.

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

p

s

i

FUEL SERVICE TOOLS

72

Fuel Injection Comparison Chart (Adapters, Fittings, and Accessories)

Part No. Description

7896 Fuel line disconnect tool set, 5/16"

red and 3/8" blue. (Same as Kent-

Moore J-39504.) Wt., 7 oz.

7902 Chrysler fuel injection fitting.

Wt., 13 oz.

7904A D-Karbonizer

4

intake system

cleaning fluid. Case of 12 cans.

Wt., 13 lbs., 10 oz. See page 67.

7915 Fuel injection quick coupler adapter.

Wt., 2 oz.

7923 Ford fuel injection adapter.

Wt., 5 oz.

7951 Ford idle speed control tester.

Wt., 9 oz.

518356 Fuel line adapter (CIS).

Wt., 12 oz.

518472 16 mm x 1.5 Internal o-ring adapter.

Wt., 3 oz.

518473 14 mm x 1.5 External o-ring adapter.

Wt., 2 oz.

518474 14 mm x 1.5 Internal o-ring adapter.

Wt., 2 oz.

518476 Ford hairpin adapter (5/16").

Wt., 5 oz.

518477 Fuel injection seal kit.

Wt., 2 oz.

518478 Single-end hose adapter (1/4", 5/16",

3/8"). Wt., 12 oz..

518480 Double-end hose adapter (5/16", 3/8").

Wt., 3 oz.

518481 16 mm x 1.5 external o-ring

Wt., 2 oz.

518482 Fuel return line plug (M14 x 1.5

external). Wt., 3 oz.

518483 3-1/2" Gauge, 0–100 psi, 0–7 BAR.

protective boot. Wt., 12 oz.

518484 M10 x 1.0 internal o-ring adapter.

Wt., 10 oz.

518485 M8 x 1.0 Internal o-ring adapter.

Wt., 10 oz.

518486 M12 x 1.5 Internal swivel adapter.

Wt., 1 oz.

518487 GM TBI fuel pressure adapter.

(16 mm x 1.5). Wt., 5 oz.

Part No. Description

518488 Quick-disconnect fitting (M8 x 1.0 x

3

5

⁄

8

" long external o-ring). Wt., 3 oz.

518489 Quick-disconnect fitting (M10 x 1.0

external o-ring). Wt., 2 oz.

518490 Quick-disconnect fitting (M6 x 1.0

external o-ring). Wt., 3 oz.

518491 Quick-disconnect banjo fitting

(M8 x 1.0 external). Wt., 3 oz.

518492 Quick-disconnect banjo fitting

(M10 x 1.0 external). Wt., 3 oz.

518493 Quick-disconnect banjo fitting

(M12 x 1.5 external). Wt., 3 oz.

518494 Quick-disconnect banjo fitting

(M12 x 1.25 external). Wt., 3 oz.

518495 Ford adapter, Schrader, .308 x 32

thread (Ford EFI). Wt., 2 oz.

518496 M16 x 1.5 External & internal swivel

adapter. Wt., 2 oz.

518497 1/4" Pipe External & internal swivel

adapter. Wt., 5 oz.

518498 M14 x 1.5 External & internal swivel

adapter. Wt., 2 oz.

518499 Ford spring lock adapter. 2003

– newer with returnless fuel system.

Wt., 7 oz.

518501 M14 x 1.5 External banjo bolt.

Wt., 2 oz.

518527 3/8" Hairpin adapter.

Wt., 5 oz.

518530 Hose assembly with relief valve.

Wt., 1 lb. 2 oz.

518534 Adapter set (

5

⁄

8

–18 external, 45°

inverted flare). Wt., 3.5 oz.

518535 Adapter set (

5

⁄

8

–18 internal, 45°

inverted flare). Wt., 3.5 oz.

518536 Quick-disconnect fitting

(M8 x 1.0 external o-ring). Wt., 2 oz.

518537 M8 x 1.0 Internal o-ring adapter (long).

Wt., 5 oz.

518542 GMC/Chrysler adapter (7/16 x 20).

Wt., 6 oz.

528177 7/16 x 20 GM/Chrysler elbow adapter.

Wt., 4 oz.

528178 7/16 x 20 GM/Chrysler straight adapt

-

er (short). Wt. 4 oz.

528180 Low-pressure gauge 0–15 psi

(0–1 BAR). Wt. 12 oz.

528182 16 mm x 1.5 elbow GM TBI

fitting. Wt. 4 oz.

528183 3/8 hairpin adapter.

Wt. 4 oz.

528766 M12 x 1.0 Double Banjo Bolt.

Wt., 5 oz.

528767 M8 x 1.0 Double Banjo Bolt.

Wt., 2 oz.

528768 M12 x 1.25 Double Banjo Bolt.

Wt., 2 oz.

FUEL SERVICE TOOLS

73

Fuel Service Tools

Part No. Description

528541 5/8 x 18 flare straight adapter.

Wt. 3 oz.

528769 Banjo fitting (M8 banjo).

Wt., 3 oz.

528770 Quick-disconnect fitting (.430 Ø exter-

nal) (Mitsubishi/Chrysler). Wt., 3 oz.

528771 Quick-disconnect fitting (.580 Ø exter

-

nal) (Mitsubishi/Chrysler). Wt., 3 oz.

528772 Quick-disconnect fitting (

5

⁄

8

" Ø external)

(Mitsubishi). Wt., 5 oz.

Fuel Injection Adapters, Fittings, and Accessories

Part No. Description

528773 O-ring and washer set for kit No. 6571.

Wt. 1 oz.

528774 O-ring and washer set for kit No. 6570.

Wt. 1 oz.

528776 Ford EFI Adapter.

Wt. 4 oz.

528779 16 mm x 1.5 Internal union adapter.

Wt. 2 oz.

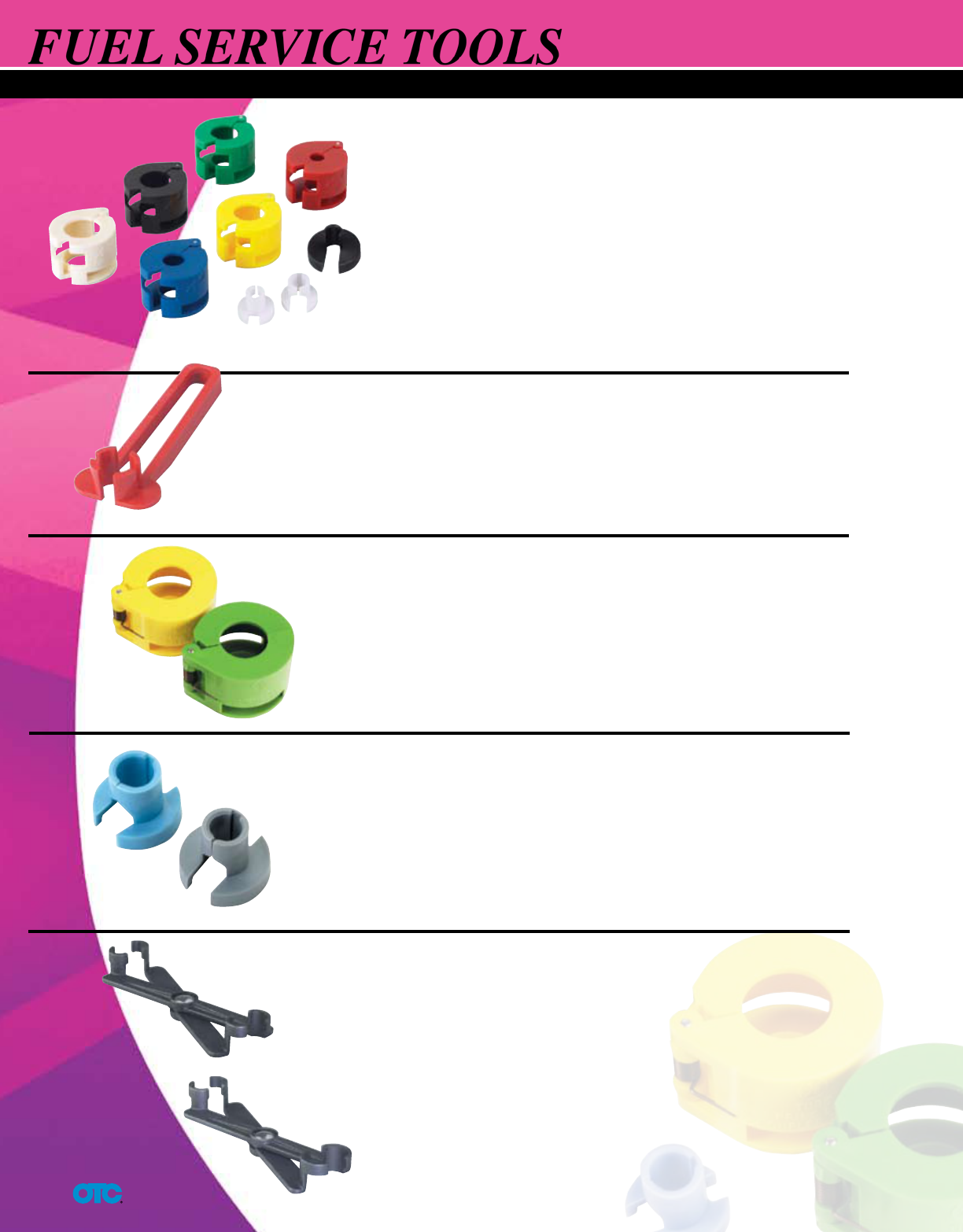

Noid Lite/ IAC Test Kits

• Noid Lites are a proven test device to quickly determine

if the electrical signal is present at the fuel injector.

• Simplest method for eliminating the EFI system or idle

air control as possible faults on no-start vehicles.

• Disconnect the fuel injectors, plug in a Noid Lite, and

crank the engine. A flashing noid light indicates normal

pulsing voltage.

No. 3050C – Noid Lite Test kit. Wt., 1 lb. 1 oz.

Set includes: (available separately)

No. 7187 – GM TBI Noid Lite. Wt., 2 oz.

No. 7188 – Bosch PFI Noid Lite. Wt., 2 oz.

No. 7601 – Ford TBI Noid Lite. Wt., 2 oz.

No. 6023 – GM Multec 2 Noid Lite. Wt., 2 oz.

No. 7602 – GM PFI Noid Lite. Wt., 2 oz.

No. 7608 – Geo TBI Noid Lite. Wt., 2 oz.

No. 7828 – GM SCPI Noid Lite. Wt., 2 oz.

No. 6266 – Bosch 2 Noid Lite. Wt., 2 oz.

No. 6260 – Fiber optic Noid Lite extension. Wt., 5 oz.

No. 3054C – Noid Lite/IAC test kit. Wt., 1 lb. 3 oz.

Set includes: (available separately)

No. 7187 – GM TBI Noid Lite. Wt., 2 oz.

No. 7188 – Bosch PFI Noid Lite. Wt., 2 oz.

No. 7601 – Ford TBI Noid Lite. Wt., 2 oz.

No. 6023 – GM Multec 2 Noid Lite. Wt., 2 oz.

No. 7602 – GM PFI Noid Lite. Wt., 2 oz.

No. 7608 – Geo TBI Noid Lite. Wt., 2 oz.

No. 7828 – GM SCPI Noid Lite. Wt., 2 oz.

No. 6266 – Bosch 2 Noid Lite. Wt., 2 oz.

No. 6260 – Fiber optic Noid Lite extension. Wt., 5 oz.

No. 3052S – ’82 and newer GM TBI/PFI IAC tester with

square 4-pin connector. Wt., 2 oz.

No. 3053S – ’87 and newer Model 700 TBI/PFI with flat 4-pin

connector. Wt., 2 oz.

• Expanded set of eight specific Noid Lites covers:

GM PFI, Ford TBI, Geo TBI, Bosch PFI, GM TBI,

GM SCPI, Bosch 2, and Multec 2. Also includes

two GM IAC testers (flat and square four-connector

applications) with red and green LEDs.

• Kits come in molded plastic cases and include

a fiber optic Noid Lite extension that allows for

convenient remote viewing of noid lite flashing

from the driver’s seat.

Typical Noid Lite

3050C

3054C

FUEL SERVICE TOOLS

74

Fuel Service Tools

Fuel Injection Tester

Fuel injectors can pass a resistance test but still fail under

load. With this tool, you can check and balance fuel injectors.

Also tests fuel injector coil windings under load, and detects

intermittent fuel injector coil faults. Adjustable current output.

Works on both throttle body and multiport fuel injectors. TBI

adapter included.

No. 3397 – Fuel injector tester. Wt., 3 lbs., 5 oz.

Fuel Injection Pulse Tester

Fuel injector testing requires precision equipment. This

vehicle-powered tool fills that requirement. It enables you

to check cylinder balance by firing individual injectors at

1/2-second increments in three different ranges: 1 pulse

of 500 milliseconds, 50 pulses of 10 milliseconds,

100 pulses of 5 milliseconds.

• Power and output lights indicate test activation.

• Includes wiring harness adapter and instructions.

No. 3398 – Fuel injection pulse tester. Wt., 8 oz.

No. 306677 – Replacement lead. Wt., 2 oz.

General Motors IAC Signal Test Lights

For checking the electronic control module signal

that provides direction to the idle air control motor on

General Motors vehicles with throttle body or port fuel

injection systems.

No. 3051 – Set consists of Nos. 3052S and 3053S. Wt., 4 oz.

No. 3052S – Signal test light for 1982 and newer GM TBI

and PFI fuel injection systems with a square 4-pin connector.

Wt., 2 oz.

No. 3053S – Signal test light for 1987 and newer GM Model

700 TBI and PFI fuel injection systems with a flat 4-pin

connector. Wt., 2 oz.

Fiber Optic Noid Lite Extension Cable

•

Four-foot length permits easy viewing of Noid Lite signal.

Used with OTC’s Nos. 7187, 7188, 7601, 7602, 7608, 7828,

6023, and 6266, as well as other brands of Noid Lites.

•

Noid Lite is inserted into cup end of extension cable, then

plugged into vehicle’s wiring harness. Fiber optic cable is routed

out of engine compartment with end placed where it can be

observed. Engine is cranked, and flashing at end of extension

indicates normal injector pulsing voltage.

• Suction cup at end of extension cable permits secure

placement on hood, fender, windshield, etc., without damage

to surface.

No. 6260 – Fiber optic Noid Lite extension cable. Wt., 5 oz.

Similar to Kent-

Moore J-34730-225

3397

3398

3052S

6260

3053S

FUEL SERVICE TOOLS

75

Fuel Service Tools

Full-Coverage Disconnect Tool Set

If you’re working on Chrysler, Ford, or General Motors vehicles,

this set will make your job easier. The tools are designed for

heater hoses, transmission oil coolers, air conditioning and

fuel lines. They’re approved by vehicle manufacturers and will

not damage the fittings being disconnected. Tool Nos. 518092,

518896, 518897, 518898, 518899, 518900, and 518901 are

spring-loaded in the closed position to deflect any spray that

occurs when lines are disconnected.

• Comes in blow-molded case.

No. 6508 – Disconnect tool set. Wt., 4 lbs., 8 oz.

Contents of set:

Tool Description

440384 GM hydraulic clutch line

disconnect tool.

440486 GM transmission oil

cooler line.

511410 Fuel line disconnect tool.

511413 Fuel line disconnect tool.

518902 Heater hose disconnect tool.

519158 Fuel line disconnect tool set.

518582 Fuel line disconnect tool.

518583 Fuel line disconnect tool.

518584 Fuel line disconnect tool.

518896 Fuel line disconnect tool.

(Yellow,

3/8"

)

518897 A/C spring lock coupling tool.

(Black,

5/8"

)

518898 A/C spring lock coupling tool.

(Blue,

1/2"

)

518899 Fuel line disconnect tool.

(Green,

1/2"

)

518900 A/C spring lock coupling tool.

(Red,

3/8"

)

Tool Description

518901 A/C spring lock coupling tool.

(White,

3/4"

)

519067 Fuel line disconnect tool.

519068 Fuel line disconnect tool.

519151 Quick disconnect tool.

519152 Oil cooler line disconnect

tool.

519153 Clutch coupling tool.

519154 Fuel line coupling tool.

519155 Chrysler fuel line disconnect

tool.

519156 Ford heater hose disconnect

tool.

519157 GM heater line quick connect

separator.

519159 Oil cooler line disconnect

tool.

6508

FUEL SERVICE TOOLS

76

Fuel Service Tools

Ford Fuel Line Disconnect Tool Set

These tools will easily disconnect the spring lock couplings of

fuel lines on Ford’s throttle body and port fuel injection systems.

The tools are spring-loaded and durable, and they enclose the

line to help deflect spray.

• Tools fit 3/8" and 1/2" lines.

No. 7337 – Ford fuel line disconnect tool set. Includes 7335

(3/8" yellow) and 7336 (1/2" green) disconnect tools. Wt., 4 oz.

Disconnect Tool Set

Designed for A/C lines, fuel lines, and transmission cooler lines.

• Contains 3/8", 1/2", 5/8", and 3/4" spring lock disconnect tools

for A/C lines on 1981 thru 2006 Ford cars and trucks, 1994

thru 2006 Chrysler and Jeep vehicles.

• Contains the 3/8" and 1/2" fuel line disconnect tool for Ford

vehicles.

• Contains the 5/16" and 3/8" fuel line disconnect tools for GM

and Chrysler vehicles.

• Contains the transmission oil cooler line disconnect tool used

on many GM and Ford vehicles.

No. 6517 – Disconnect tool set. Wt. 7 oz.

GM Fuel Line Disconnect Tool

Applications: 2002–newer Tahoe and light-duty trucks with

the 5.3L V8 engine.

•

This is a required tool to remove the fuel line from the fuel filter.

No. 6603 – GM fuel line disconnect tool. Wt. 1 oz.

Similar to Kent-Moore

No. J-46363.

6517

6603

7337

Fuel Line Disconnect Tools

• Special low-profile design works in close quarters on GM,

Ford, and Chrysler vehicles where there is limited clearance

between the fuel line fittings and fuel filters, fuel rails, or

sending units. Both tools are designed to access the center

port on the GM fuel tank sending unit.

No. 6509 – For 3/8" & 5/16" applications. Will also service

1999–current GM pickups, and 2000–current Suburban, Tahoe,

and Yukon gasoline vehicles. Wt., 3 oz.

No. 6511 – For 3/8" and 1/2" applications. Will also

service 2001–current 3/4- & 1-ton trucks with the Duramax

diesel engines. Wt., 3 oz.

6509

6511

Similar to Ford

No. 310-5039

(T90T-9550-S)

Fuel Line Disconnect Tool Set

These two disconnect tools are designed to fit quick-connect

fuel line fasteners. They’ll work on Chrysler, Ford, or GM

vehicles, and separate fuel lines without damaging the

connectors.

• Tools fit 5/16" and 3/8" lines.

No. 7361 – Fuel line disconnect tool set. Includes 7370 (5/16"

gray) and 7371 (3/8" blue) disconnect tools. Wt., 1 oz.

7361

FUEL SERVICE TOOLS

77

Fuel Service Tools

Rubber Line Clamp Set

• Set of two clamps. Used to quickly shut off flow from

vacuum, brake, and fuel lines.

• Enables you to clamp and hold hose without damage.

No. 4506 – Rubber line clamp set. Wt., 6 oz.

4506

Fuel and Air Conditioning Line

Release Tool

• This spring-lock coupling release tool easily separates

fittings on fuel and air conditioning lines.

• Tool sizes are 3/4", 5/8", 1/2", and 3/8".

No. 4494 – Fuel and air conditioning line release tool. Wt., 5 oz.

4494

7-Piece Sensor Socket Set

Includes:

No. 4673-1 – 29 mm pressure / vacuum switch socket.

No. 4673-2 – 7/8" vacuum switch socket.

No. 4673-3 – 27 mm oil pressure sending unit socket.

No. 4673-4 – 7/8" vacuum switch socket.

No. 4673-5 – 1-1/16" & 1" oil pressure sending unit socket.

No. 4673-6 – 22 mm heated oxygen sensor wrench.

No. 4673-7 – 7/8" short oxygen sensor socket.

No. 4673 – 7-Piece sensor socket set. Wt. 4 lbs. 10 oz.

4673

Similar to Ford

No. T79P-9472-A

7189

Oxygen Sensor Socket

• Designed to easily remove an oxygen sensor.

• Heat-treated cast steel.

• 7/8" hex, 1/2" square drive (double square for easy access).

No. 7189 – Oxygen sensor socket. Wt., 8 oz.

6931

Oxygen Sensor Socket

• Works on all domestic and imported vehicles with oxygen sensors.

• Slot in socket’s side allows wire clearance.

• Outside rib provides added strength, yet does not restrict access to sensors.

• 1/2" square drive, 1" male hex drive on top, 7/8" six-point opening, 3-7/8" long

No. 6931 – Oxygen sensor wrench. Wt., 1 lb.

Ford Fuel Line Disconnect Tool Set

Here’s the best tool for easy, frustration-free fuel line separation.

As you put the tool on the fuel line coupling, its fingers depress

the retaining collar to release the fuel line, preventing component

damage.

• Works on 1990 to 1995 Ford Ranger and Explorer models

fitted with 4.0L, 6-cylinder engines.

No. 519154 – Ford fuel line coupling tool. Wt., 2 oz.

519154

FUEL SERVICE TOOLS

78

Fuel Service Tools

Similar to Ford

No. 310-003

(T75L-9600-A)

7416

Chrysler Fuel Pump Module Spanner Wrench

Removes and installs the fuel pump retaining ring that holds

the fuel pump module onto the gas tank. Works on most

1994–2005 Chrysler vehicles, and 1995-2004 Jeep vehicles.

No. 7998 – Chrysler fuel pump module spanner wrench.

Wt., 1 lb., 5 oz.

Propane Enrichment Kit

• Ensures a correct idle mixture and compliance with

emission standards.

• Works on domestic or imported vehicles that have

carburetors.

• Uses standard 14-oz. propane cartridge.

No. 7148 – Propane enrichment kit. Wt., 14 oz.

Fuel Emission Flow Meter

• Enables precise adjustment of engine idle mixtures.

• Works with OTC No. 7148 propane enrichment kit to monitor

the propane going into the engine.

• Works on domestic or imported vehicles that have

carburetors.

No. 7416 – Fuel emission flow meter. Wt., 6 oz.

7148

Fuel Tank Lock Ring Wrench

Universal design allows tool to fit fuel tank lock rings on Ford,

Chrysler, and GM vehicles with gas engines.

• Works on: 2004–newer Ford F-150 trucks; 2004–newer

Chrysler / Dodge minivans, PT Cruiser, Dakota, and Durango;

2004–newer Chevy 1/2-ton and 3/4-ton trucks; and

2005–newer Jeep vehicles.

• Tool easily removes and installs lock ring on the fuel tank

when servicing the fuel pump or fuel sending unit.

• Used with a 1/2" drive ratchet or breaker bar.

No. 6599 – Fuel tank lock ring wrench. Wt. 1 lb. 8 oz.

6599

Mercedes-Benz Fuel Tank Service Tool Kit

• Tool kit designed to remove fuel tank lids and

plastic fuel tank cups to allow service on the

fuel pump and/or the fuel sending unit.

• Works on Mercedes-Benz models W202 and W210.

No. 6598 – Mercedes-Benz Fuel Tank Service Tool Kit.

Wt. 4 lb. 2 oz.

6598

Exhaust Back Pressure Gauge

Now you can quickly read back pressure to determine the amount

of restriction in an exhaust system. This gauge accurately measures

through the oxygen sensor hole. Its large dial clearly shows pressure

from 0–8 psi. The system has a stainless steel braided tube to

withstand high-heat conditions.

• Includes a universal adapter for vehicles with thermactor systems.

• Works on domestic and imported vehicles.

No. 7215 – Exhaust back pressure gauge with universal adapter.

Wt., 1 lb., 3 oz.

7215

7998

Similar to Miller

No. 6856

PULLERS

205

Quick Finder Index

Quick Finder Index...

Puller “How-to” Information . . . . . . . . 206–207

Puller Safety Tips . . . . . . . . . . . . . . . . . . . . 207

Protective Blankets. . . . . . . . . . . . . . . . . . . 207

Mechanical “Grip-O-Matic” Pullers . . . . . . . 208

Hydraulic “Grip-O-Matic” Pullers . . . . . . . . 209

Mechanical Push-Pullers . . . . . . . . . . . . . . 209

Hydraulic Push-Pullers . . . . . . . . . . . . . . . . 210

Pulling Attachments . . . . . . . . . . . . . . . . . . 211

Puller Adapters . . . . . . . . . . . . . . . . . . 211–212

Slide Hammer Pullers. . . . . . . . . . . . . 213–214

Bearing Pullers . . . . . . . . . . . . . . . . . . 214–215

Puller Sets . . . . . . . . . . . . . . . . . . . . . 215–222

PULLERS

206

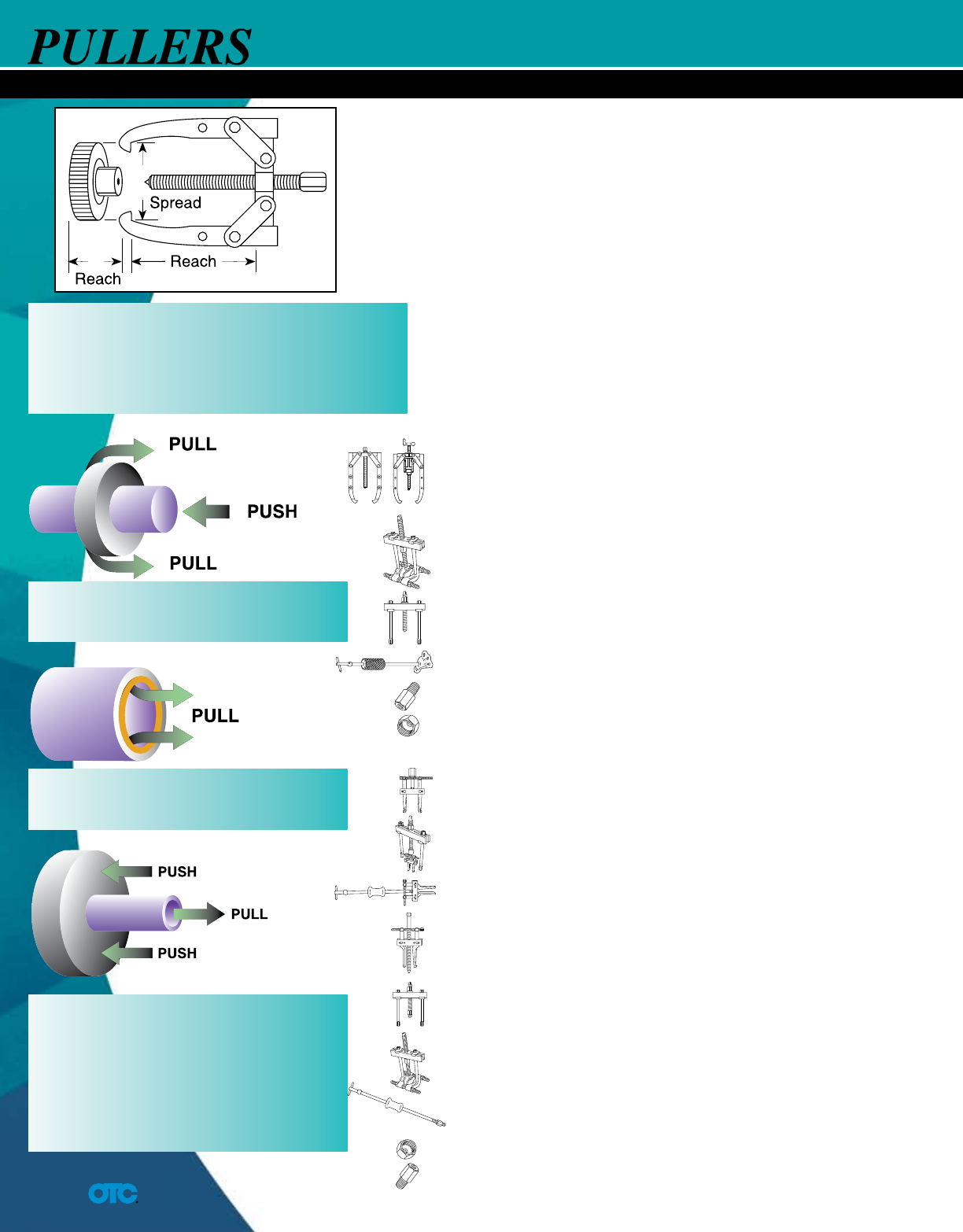

Selecting the “Right” Puller

You can solve the 3 basic pulling problems…

The first thing you have to do is identify exactly what your

particular pulling problem is. Once you recognize the problem,

you can go on to select the right tool to solve it.

How to select the “RIGHT” puller

1: Determine the type of puller or puller combination.

Which puller type is best for “getting a grip” on the part?

Is a combination of puller types required?

2: Determine the “REACH” needed.

The puller you

select must have a “reach” equal to or larger than the

corresponding sizes of the part.

3: Determine the “SPREAD” needed.

The width of the part to

be pulled will determine the “spread” required.

4: Estimate the force required.

A puller with the correct “reach”

and “spread” will usually have enough power. When in doubt,

always use the next larger size. More power may be needed for

rusted parts, or when the “area of resistance” is large.

The tools to use when pulling something off a shaft:

Jaw-type puller, either manual or hydraulic. (For extra force and

convenience use a hydraulic puller.) Both are available in 2- or

3-jaw versions and are used to grip the outer circumference of

an attachment.

Bearing pulling attachment. Provides “knife-like” edges to get

behind the component, or when there isn’t a good gripping area on

the part to be pulled.

Push-Puller

®

with attachments. External-internal adapters can

thread directly into tapped holes on a component. The splitter gets

behind the component to prevent damage to the part.

Slide hammer puller with selected attachments for multiple

light-duty pulling tasks.

A variety of OTC adapters can be used to protect a shaft, bridge

a hole, thread into tapped holes, or assist installation.

The tools to use when pulling something out of a hole:

Internal pulling attachments have narrow jaws which extend

through the center of the part to be pulled. They provide a straight

pull and avoid damage to housings. Designed for use with Push-

Pullers or slide hammer pullers.

Push-Puller in combination with internal pulling attachment. Both

mechanical and hydraulically powered versions are available.

Here a slide hammer puller is combined with an internal pulling

attachment. Ideal for removing parts from blind holes, especially

when there is no housing to brace puller legs against.

When there is a shaft to bear against, a forcing screw of the

correct size may be used in combination with an internal pulling

attachment.

The tools to use when pulling a shaft out of something:

Push-Puller

®

with threaded adapter. Use a mechanical or hydraulic

puller, depending on the size of the shaft to be pulled.

When the housing lacks sufficient surface for the puller legs to bear

against, a pulling attachment may be used to provide support.

Slide hammer puller with threaded adapter – either external-internal

or internal can be used.

Internal adapters are fastened to the external threaded end of the

shaft to pull while pushing against the housing.

External-internal adapters are threaded into the shaft to pull it

while pushing against the housing.

General Rule of Thumb: Manual pullers require that

the puller screw be at least half as large (in diameter)

as the shaft of the pulling job.

Hydraulic pullers need the maximum force exerted in

tons to be 7–10 times the diameter of the shaft in inches.

1 Pulling something off a shaft.

Removing a gear, bearing, wheel, pulley, etc.,

to replace it or get at another part.

2 Pulling something out of a hole.

Internal bearing cups, retainers, or oil seals are

usually press-fitted and are difficult to remove.

3 Pulling a shaft out of something.

A transmission shaft or pinion shaft is often hard to

remove from a bore or housing. Use a Push-Puller

with adapters if you can “get ahold of” the threaded

end of the shaft. Sometimes it’s possible to push a

shaft through a housing, rather than pull it out. In

applications of this type, the puller legs must be

securely fastened to the housing and the screw

may simply bear against the shaft.

PULLERS

207

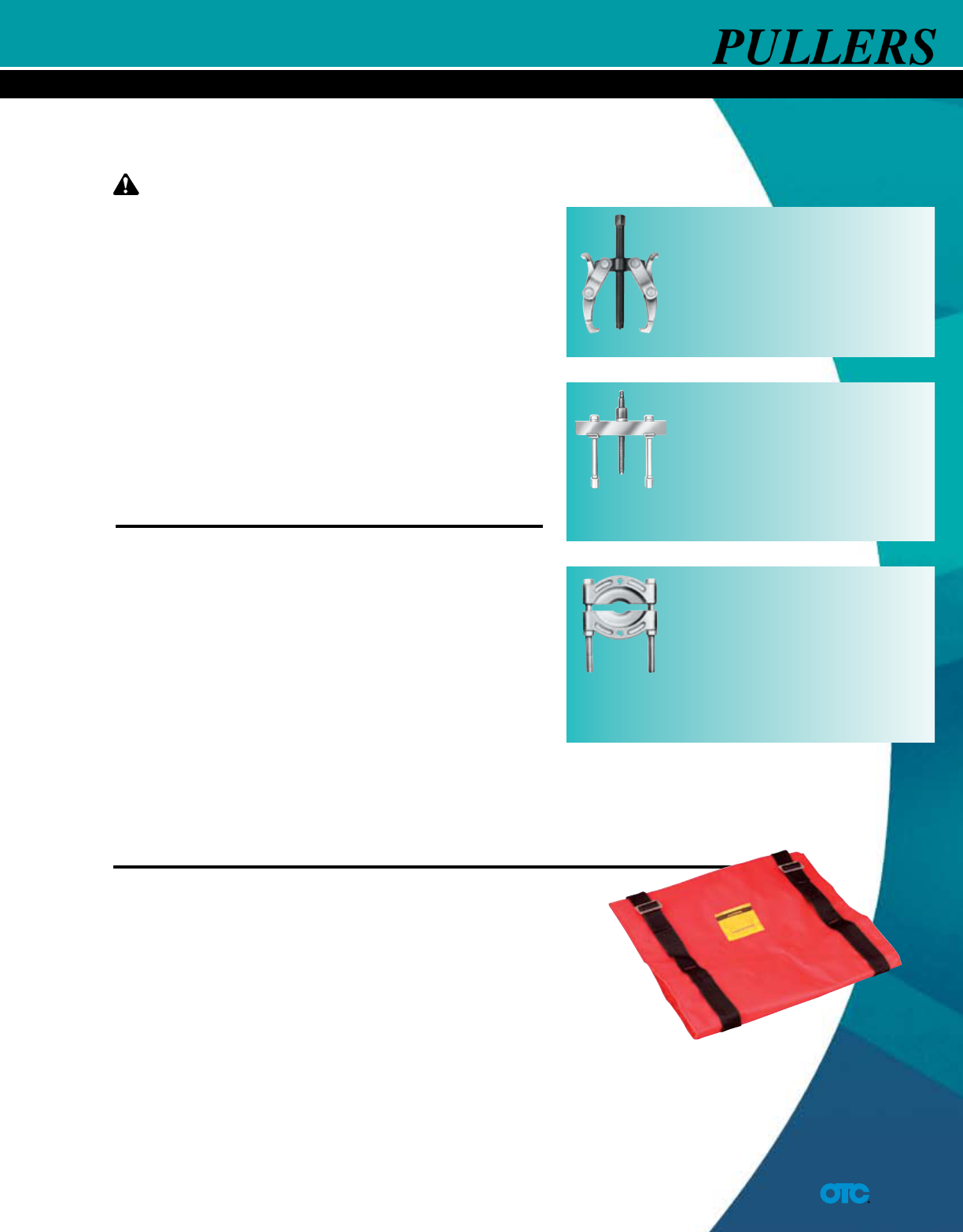

Operator Safety Comes First!

Your pulling system exerts tons of force.

You must respect this force, and observe

safety precautions at all times.

Caution

It is impossible to predict the exact force required for every pull-

ing job: setup requirements and the size, shape, and

condition of the parts being pulled vary a great deal. In

addition, the OTC Pulling System is so versatile, it is possible

that components in a pulling setup may have different tonnage

ratings. The lowest “capacity” component, then, determines

the capacity of the setup. For example: When an accessory

with a 1-ton capacity is used with a 10-ton capacity puller,

the setup can be used only at a force of one ton.

These tools should be used only by trained personnel

familiar with them. Always wear eye protection during a job,

since work parts, or the pulling tool itself, may break and parts

may fly. It is recommended to cover the work with an OTC

Protective Blanket or use a shield while force is being applied.

If you are at all unsure which tool or attachment to select,

contact Technical Services.

A Few Easy Tips to Remember

Wear safety glasses at all times!

You have only one set of eyes, so protect them from possible

flying parts.

Keep your pulling tools in shape!

Clean and lubricate the puller’s forcing screw frequently, from threads

to tip, to ensure long service life and correct operation.

Cover work with a protective blanket!

With high forces being exerted on the part being pulled, breakage

may sometimes result. By covering the work with a protective blanket,

the user reduces the danger of flying parts.

Apply force gradually!

The component should give a little at a time. Do not try to speed

up removal by using an impact wrench on the puller screw.

Use the right size puller!

If you have applied maximum force and the part has not moved,

go to a larger capacity puller. Resist sledging.

Protective Blankets

Think of them as “security blankets.” They wrap around pulling,

pressing, and other high-force jobs to protect you and your em-

ployees from work-related injuries as much as possible. They’re

made of high tensile, tear resistant ballistic nylon – similar to

military flak jackets – that, when tested, withstood the shattering

of a neck-down grade 8 bolt without any visible damage.

NOTE: Always reduce the force from the workpiece prior to removing the blanket. Protective

blankets may afford protection from injuries to users and others should part breakage occur.

Because of the variety of situations that require guarding, it is the user’s responsibility to

determine the best method of protection.

No. 1230PB – Protective blanket. 12" x 30". Wt., 2 lbs., 3 oz.

No. 2036PB – Protective blanket. 20" x 36". Wt., 3 lbs.

No. 2860PB – Protective blanket. 28" x 60". Wt., 7 lbs.

Grip-O-Matic pullers

Align puller legs and jaws.

Be sure the setup is rigid and the puller

is square with the work.

Mount puller so grip is tight!

Tighten the adjusting strap bolts when

using a jaw-type puller.

Push-Pullers

Do not couple puller legs!

The tonnage capacity of a Push-Puller is

reduced when longer-than-standard legs

are used, or when legs are in compres-

sion. The chance of breaking, bending, or

misaligning legs increases. Always use

the shortest legs possible to do the job.

Bearing pulling attachments

These attachments may not withstand

the full tonnage of the pullers with which

they are used. The shape and condition

of the part being pulled affects the ton-

nage at which the puller blocks and/or

studs may bend or break. Always select

the largest attachment that will fit the

part to be pulled.

1230PB

PULLERS

208

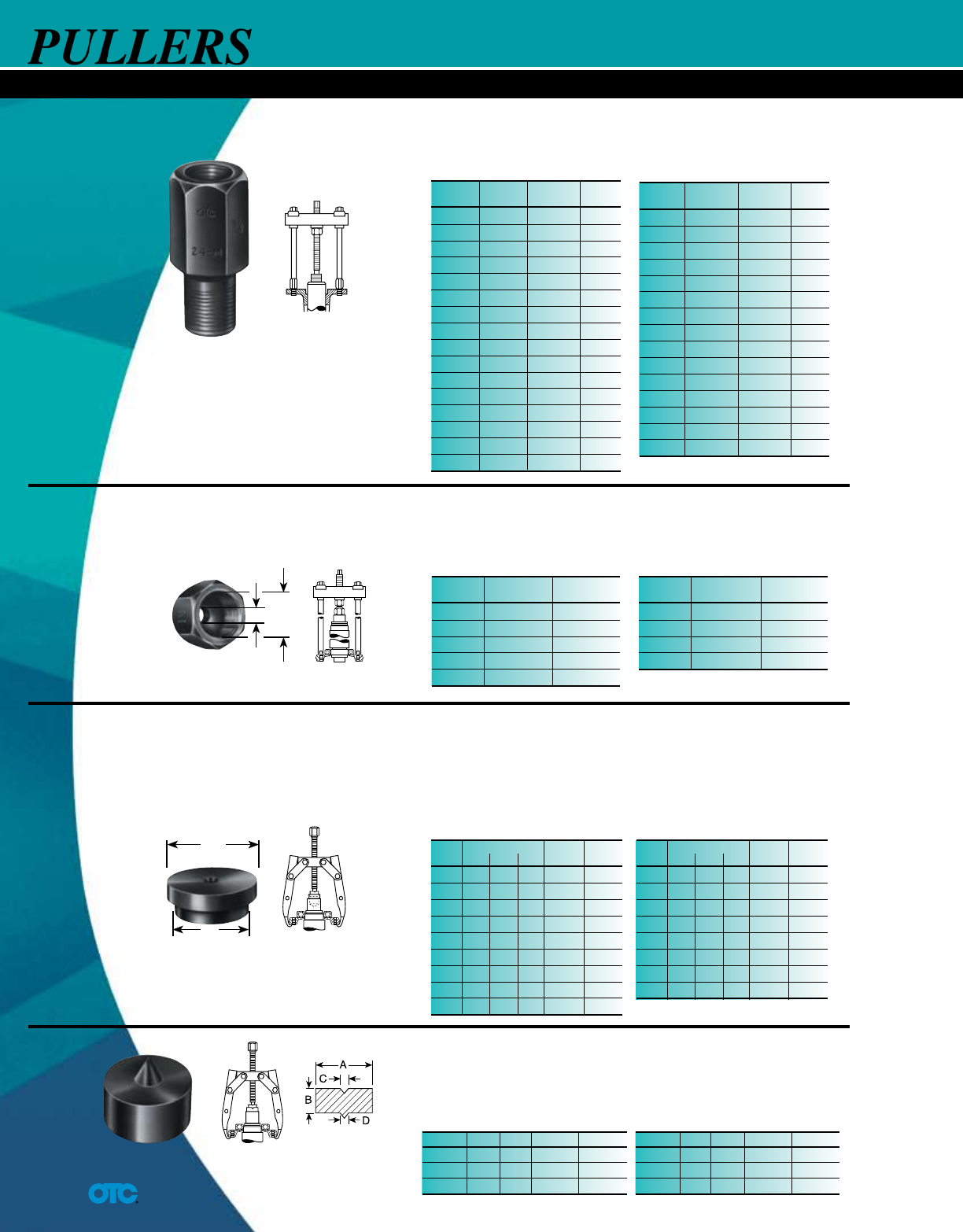

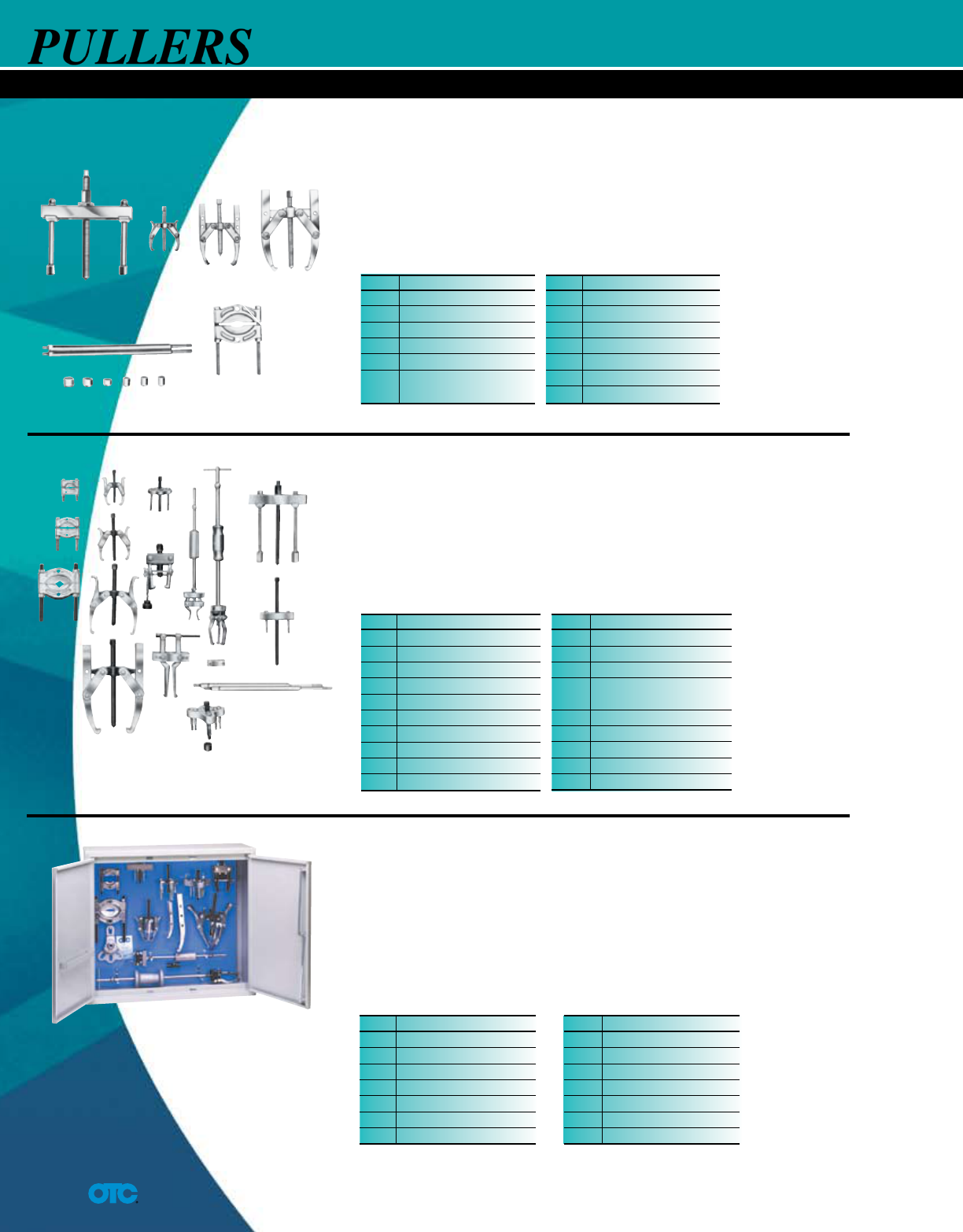

Mechanical Grip-O-Matic

®

Pullers

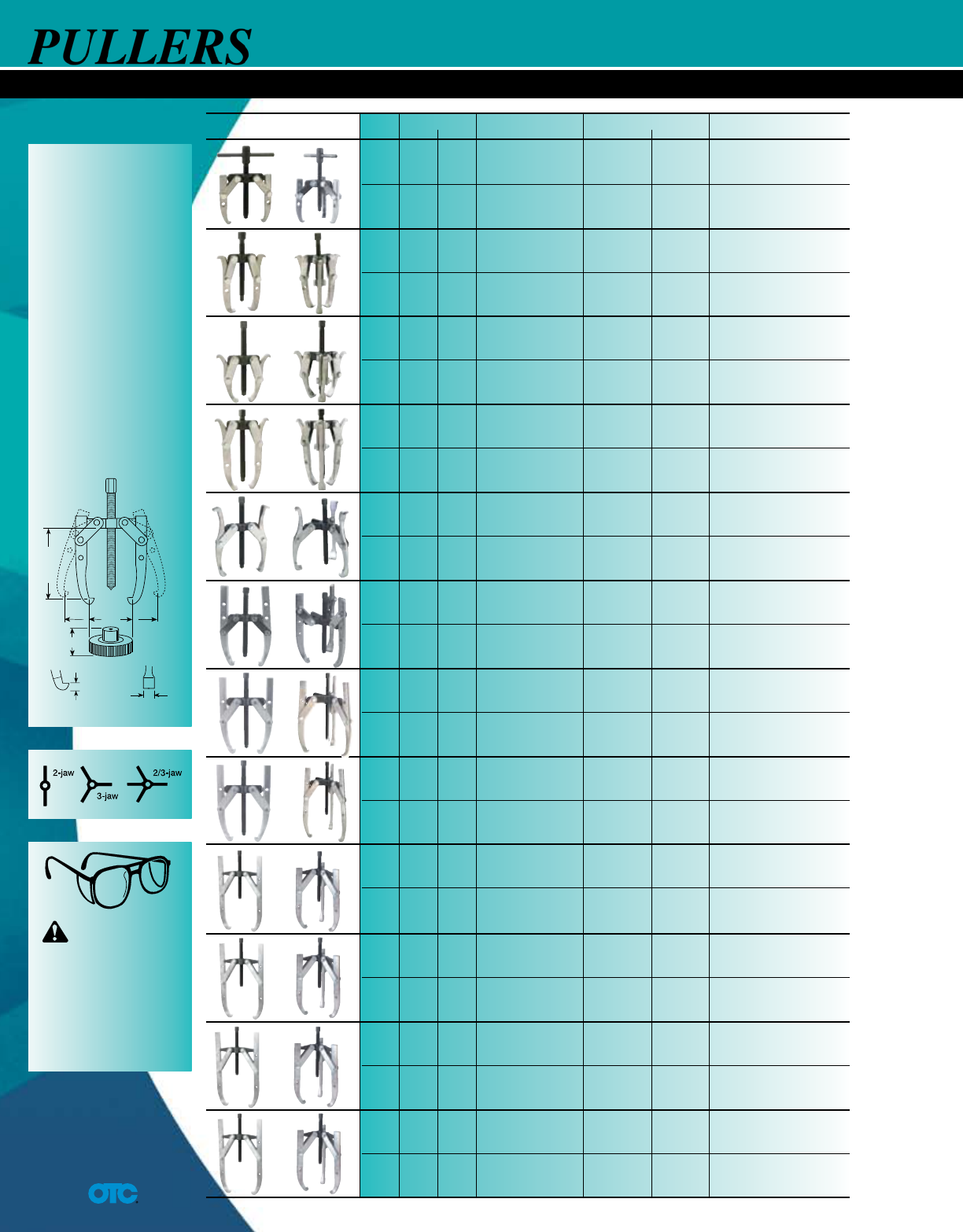

Jaw widthJaw thickness

Reach

Spread

Reach

Mechanical

Grip-O-Matic

®

Pullers

OTC has developed

the most complete line

of gear and bearing

pullers, enabling you

to remove and install

parts for fast, effective

repairs. The pullers

are forged from qual-

ity steel, heat treated,

and subjected to

rigorous tests which

exceed their rated

capacity.

No. 1020–1050

WARNING

Wear approved eye

protection when using

pullers.

See page 207 for

protective blankets

for your pulling jobs.

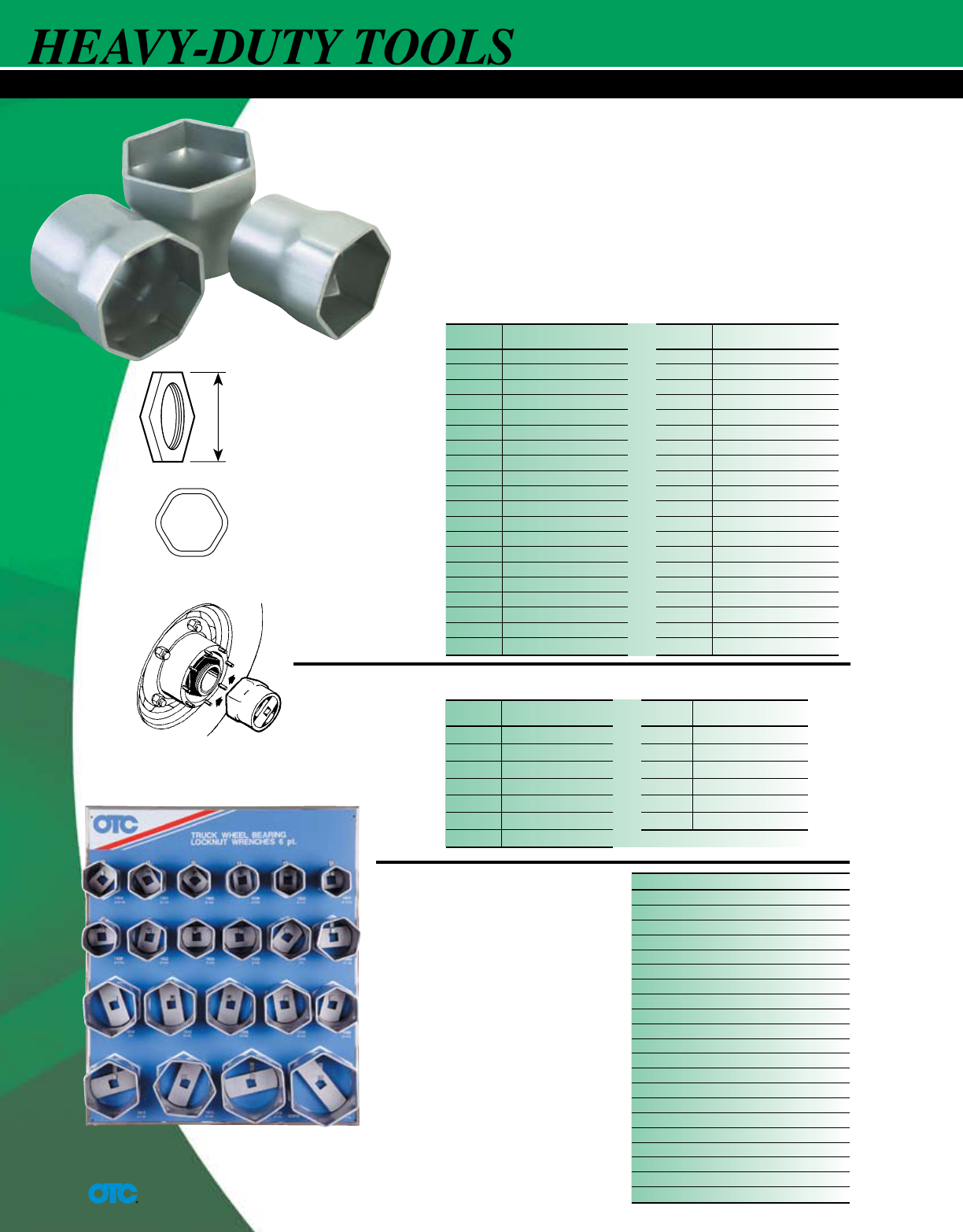

Tool MAX. JAW Capacity,

No. Reach Spread Screw Size Thickness Width Style, and Weight

1020 2-1/8" 3-1/4" 5/16"–24 x 3-7/8" 9/64" 1/4" 1-Ton,

2-Jaw; 5 oz.

1021 2-1/8" 3-1/4" 5/16"–24 x 3-7/8" 9/64" 1/4" 1-Ton,

3-Jaw; 8 oz.

1022 3-1/4" 4" 3/8"–24 x 4-7/8" Upper 3/16" Upper 1/4" 2-ton, 2-Jaw; 14 oz.

Lower 1/8" Lower 1/2" (Reversible Jaws)

1023 3-1/4" 4-3/4" 3/8"–24 x 4-7/8" Upper 3/16" Upper 1/4" 2-ton, 2/3-Jaw; 1 lb., 5 oz.

Lower 1/8" Lower 1/2" (Reversible Jaws)

1024 3-1/4" 6" 9/16"–20 x 6-15/16" Upper 5/16" Upper 3/8" 5-Ton, 2-Jaw; 1 lb., 12 oz.

Lower 1/4" Lower 3/4" (Reversible Jaws)

1026 3-1/4" 7" 9/16"–20 x 6-15/16" Upper 5/16" Upper 3/8" 5-Ton, 2/3-Jaw; 2 lbs., 12 oz.

Lower 1/4" Lower 3/4" (Reversible Jaws)

1025 5-1/2" 6" 9/16"–20 x 6-15/16" Upper 5/16" Upper 3/8" 5-Ton, Long 2-Jaw; 2 lbs.

Lower 1/4" Lower 3/4" (Reversible Jaws)

1027 5-1/2" 7" 9/16"–20 x 6-15/16" Upper 5/16" Upper 3/8" 5-Ton, Long 2/3-Jaw;

Lower 1/4" Lower 3/4" 3 lbs., 10 oz. (Rev. Jaws)

1035 5" 9" 11/16"–18 x 9" Upper 5/16" Upper 1" 7-Ton, 2-Jaw; 4 lbs., 8 oz.

Lower 11/32" Lower 1" (Reversible Jaws)

1037 5" 10-1/2" 11/16"–18 x 9" Upper 5/16" Upper 1" 7-Ton, 2/3-Jaw;

Lower 11/32" Lower 1" 6 lbs., 2 oz. (Rev. Jaws)

1036 8-3/4" 9-1/2" 11/16"–18 x 9" 11/32" 1" 7-Ton,

Long 2-Jaw; 5 lbs., 6 oz.

1038 8-3/4" 11" 11/16"–18 x 9" 11/32" 1" 7-Ton,

Long 2/3-Jaw; 8 lbs., 2 oz.

1039 11" 12" 13/16"–16 x 12" 9/16" 1" 13-Ton,

2-Jaw; 10 lbs., 13 oz.

1041 11" 12" 13/16"–16 x 12" 9/16" 1" 13-Ton,

2/3-Jaw; 16 lbs., 4 oz.

1040 15-1/4" 15-1/2" 13/16"–16 x 12" 9/16" 1" 13-Ton,

Long 2-Jaw; 13 lbs.

1042 15-1/4" 17" 13/16"–16 x 12" 9/16" 1" 13-Ton,

Long 2/3-Jaw; 18 lbs., 12 oz.

1043 14-1/2" 14" 1"–14 x 13

1

/2" 13/16" 1-9/32" 17-1/2-Ton,

2-Jaw; 23 lbs.

1045 14-1/2" 14" 1"–14 x 13-1/2" 13/16" 1-9/32" 17-1/2-Ton,

3-Jaw; 33 lbs.

1044 18-3/4" 16" 1"–14 x 13-1/2" 13/16" 1-9/32" 17-1/2-Ton,

Long 2-Jaw; 26 lbs.

1046 18-3/4" 16" 1"–14 x 13-1/2" 13/16" 1-9/32" 17-1/2-Ton,

Long 3-Jaw; 37 lbs.

1047 15-1/2" 18" 1-1/4"–12 x 15-15/16" 1-1/16" 1-1/2" 25-Ton,

2-Jaw; 37 lbs., 8 oz.

1049 15-1/2" 18" 1-1/4"–12 x 15-15/16" 1-1/16" 1-1/2" 25-Ton,

3-Jaw; 54 lbs.

1048 22-1/4" 20" 1-1/4"–12 x 15-15/16" 1-1/16" 1-1/2" 25-Ton,

Long 2-Jaw; 42 lbs., 12 oz.

1050 22-1/4" 20" 1-1/4"–12 x 15-15/16" 1-1/16" 1-1/2" 25-Ton,

Long 3-Jaw; 60 lbs.

PULLERS

209

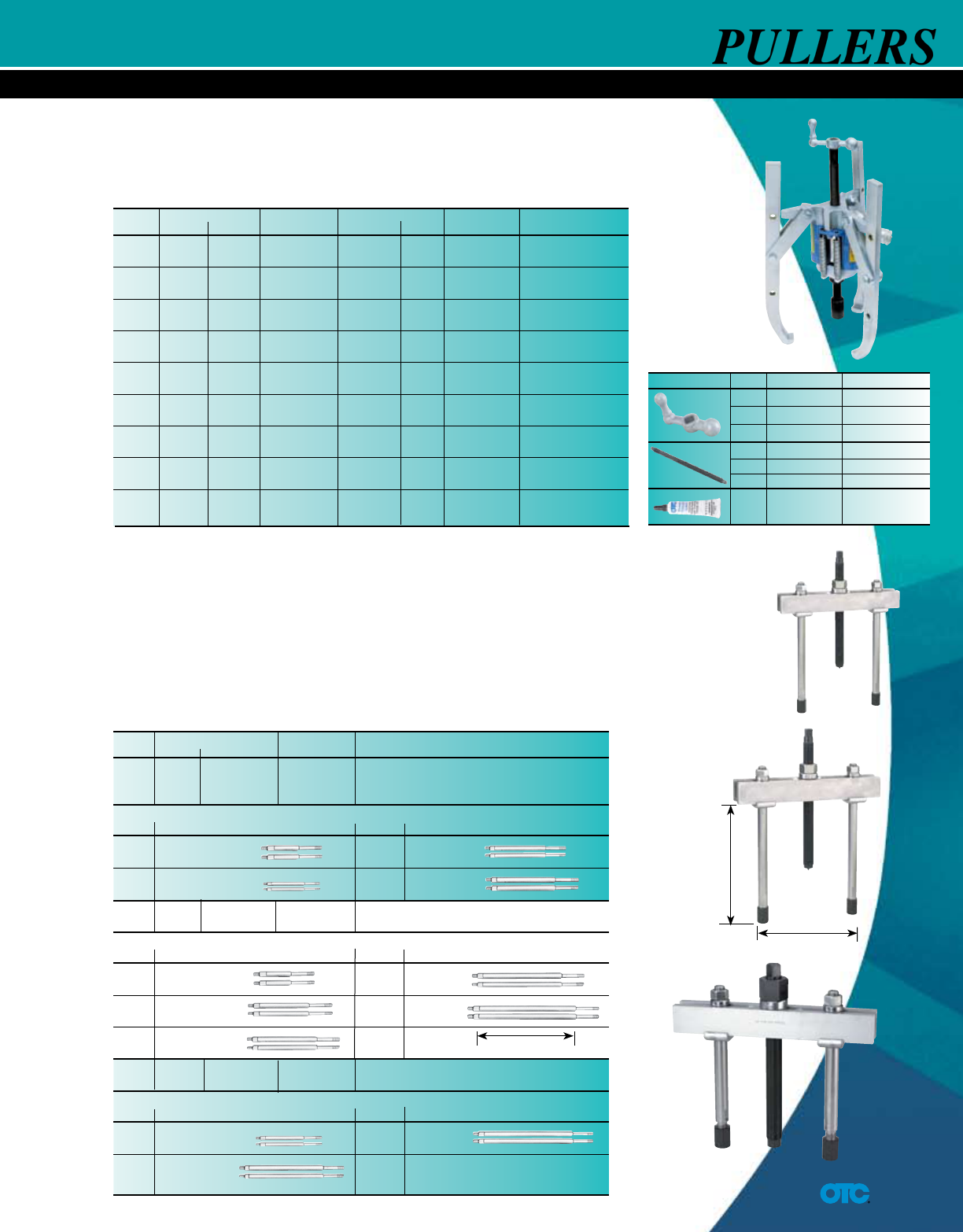

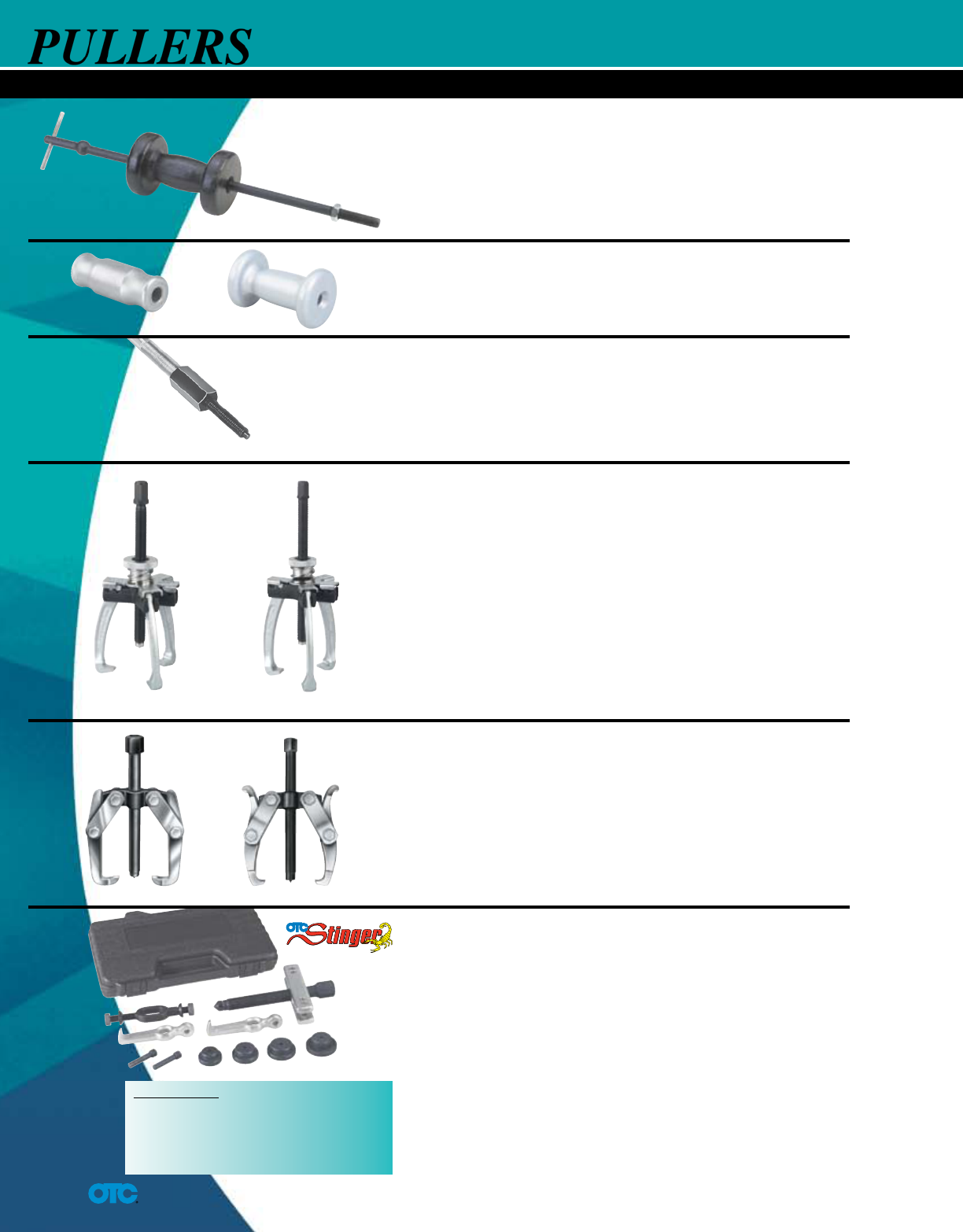

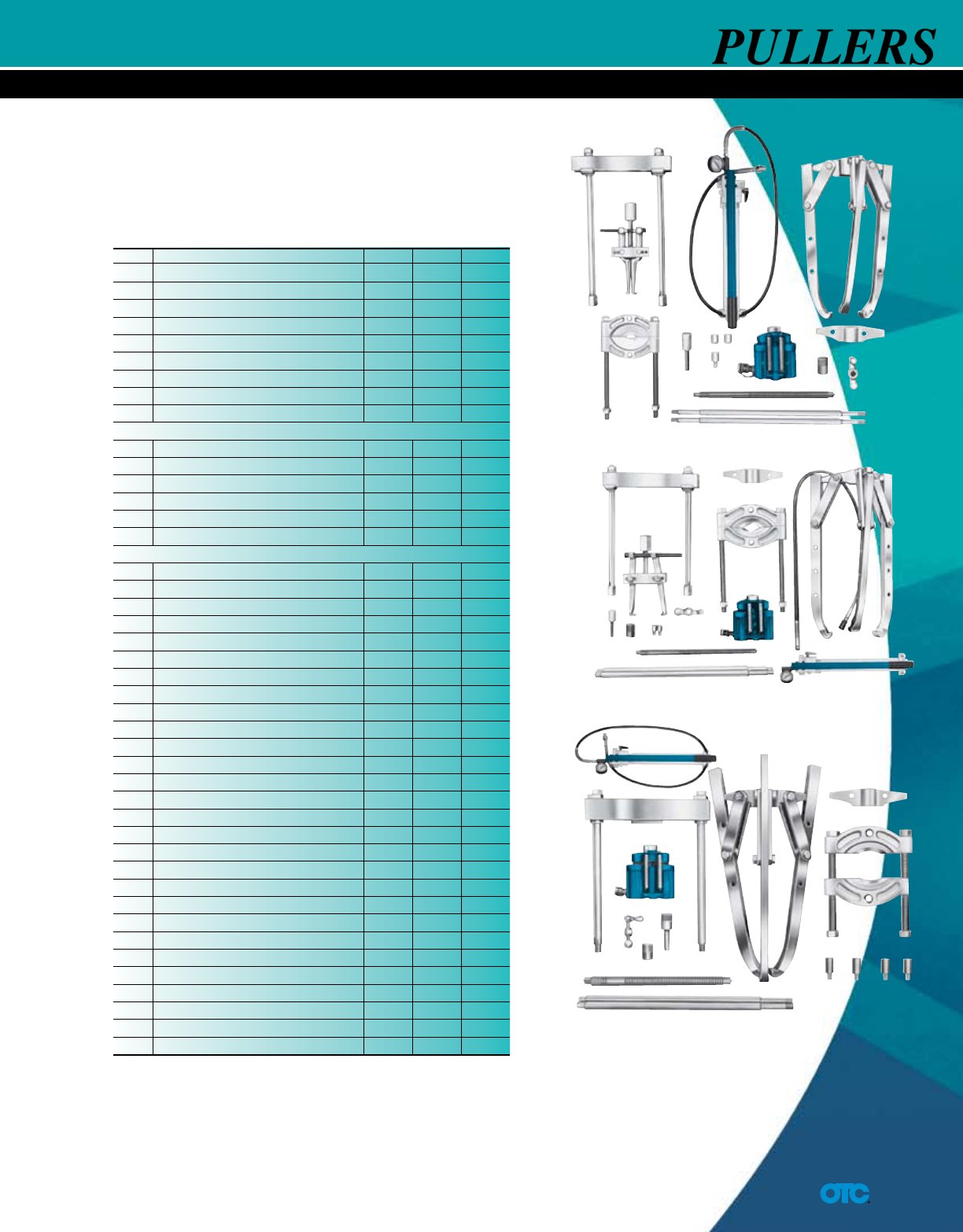

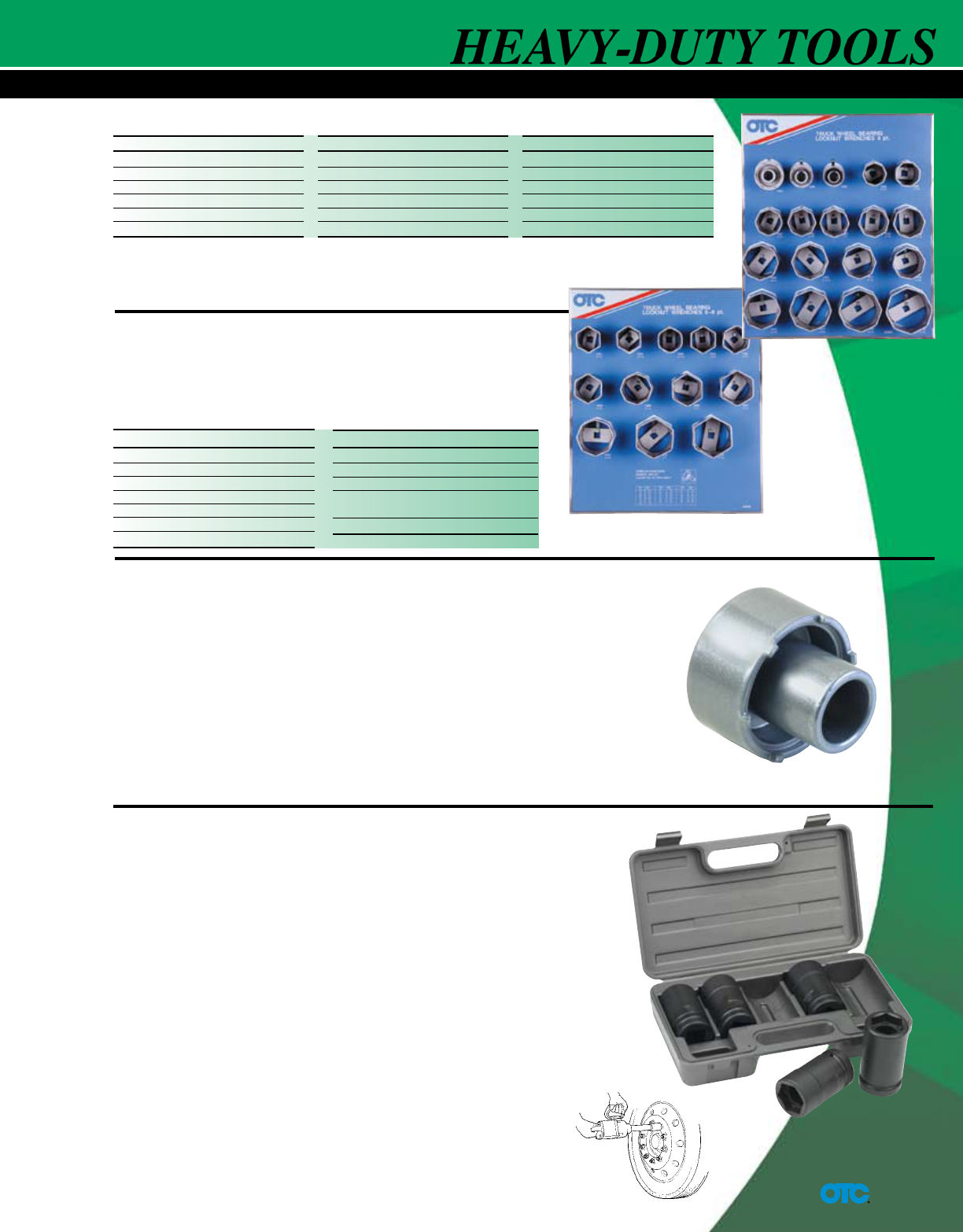

Hydraulic Grip-O-Matic

®

Pullers

MAX.

Tool No. Reach Spread Screw Size Notes / Weight

927 8-1/4" 2-1/8" – 7-1/4" 3/4"–16 x 12" 1/2" of forcing screw tip end is threaded 5/8"–18.

No. 1100 legs and No. 24827 leg ends included.

Wt., 7 lbs.

Extra Legs (pair) for No. 927 Push-Puller (Reach equals leg length plus 1-1/2" with leg end caps.)

Tool No. Leg Length & Wt. Tool No. Leg Length & Wt.

1103 4-3/4" 1102 11-3/4"

1 lb. 2 lbs., 4 oz.

1100 6-3/4" 1101 15-3/4"

1 lb., 8 oz. 3 lbs., 4 oz.

938 11-1/2" 3-1/8"–11-3/4" 1"–14 x 13-1/4" Leg ends threaded 5/8"–18. No. 1106 legs and

No. 24827 leg ends included. Wt., 20 lbs., 12 oz.

Extra Legs (pair) for No. 938 Push-Puller (Reach equals leg length plus 2" with leg end caps.)

Tool No. Leg Length & Wt. Tool No. Leg Length & Wt.

1107 4-1/2" 1105 22-1/2"

2 lbs., 8 oz. 9 lbs.

1106 9-1/2" 1108 30"

4 lbs., 8 oz. 11-1/2" lbs.

1104 16-1/2"

6 lbs., 8 oz.

939 10-1/2" 7"–16-1/4" 1-1/2"–12 x Leg ends threaded 1"–14. No. 1109 legs and

17-1/4" No. 28390 leg ends included. Wt., 44 lbs.

Extra Legs (pair) for No. 939 Push-Puller (Reach equals leg length plus 2-5/8" with leg end caps.)

Tool No. Leg Length & Wt. Tool No. Leg Length & Wt.

1109 8" 1111 28"

8 lbs. 22 lbs.

1110 18"

15 lbs.

Hydraulic Grip-O-Matic

®

Puller

No. 1065-1080 Available in 17-1/2 to 50-ton capacities. Reliable single-acting Power

Twin ram is matched with a versatile 2-jaw or 3-jaw puller. Lightweight ram can be

used in other applications. You also get an adjusting screw, speed crank, and coupler

where applicable. Hydraulic pump is not included; see index for pump listings.

Tool MAX. Ram Capacity JAW Screw Size

No. Reach Spread & Number Thickness Width & Crank No. Style and Weight

1065 11-1/2" 16" 17-1/2 Ton, 13/16" 1-9/32" 1"–8 x 20" 17-1/2 Ton, 2-Jaw;

No. 4120 No. 24814 40 lbs.

1064 11-1/2" 16" N/A 13/16" 1-9/32" N/A 17-1/2 Ton, 2-Jaw

Puller Only; 24 lbs.

1067 11-1/2" 20" 17-1/2 Ton, 13/16" 1-9/32" 1"–8 x 20" 17-1/2 Ton, 3-Jaw;

No. 4120 No. 24814 53 lbs.

1066 11-1/2" 20" N/A 13/16" 1-9/32" N/A 17-1/2 Ton, 3-Jaw

Puller Only; 37 lbs.

1073 19-7/16" 26" 30-Ton, 1-1/8" 1-5/8" 1-1/4"–7 x 24" 30-Ton, 2-Jaw;

No. 4121 No. 27198 91 lbs.

1072 19-7/16" 26" N/A 1-1/8" 1-5/8" N/A 30-Ton, 2-Jaw

Puller Only; 59 lbs.

1075 19-7/16" 34" 30-Ton, 1-1/8" 1-5/8" 1-1/4"–7 x 24" 30-Ton, 3-Jaw;

No. 4121 No. 27198 122 lbs.

1074 19-7/16" 34" N/A 1-1/8" 1-5/8" N/A 30-Ton, 3-Jaw

1080 19-7/16" 44" N/A 1-1/8" 1-5/8" N/A 50-Ton, 3-Jaw

Puller Only; 187 lbs.

No. Description Capacity in Tons

24814 Speed Crank 17-1/2

27198 Speed Crank 30

29595 Speed Crank 50

32118 Adjusting Screw 17-1/2

34758 Adjusting Screw 30

32698 Adjusting Screw 50

39448 Lube for pullers

Puller components

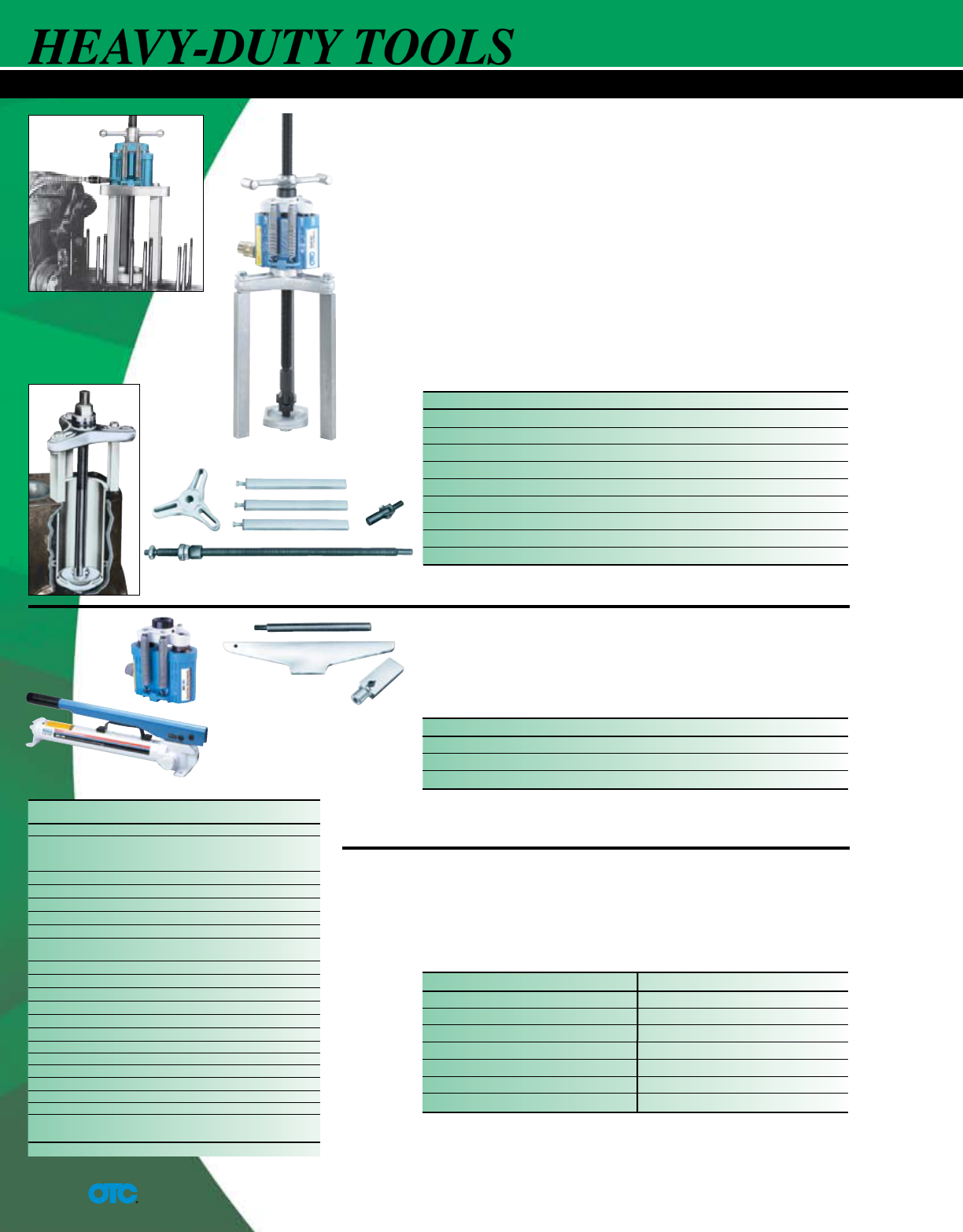

Push-Pullers

®

No. 927 – 10-Ton Capacity Can be used with No. 1123 bearing pulling attachment

or No. 679 pulley pulling attachment. May also be used with Nos. 1150, 1151, 1152,

or 1153 internal pulling attachments.

No. 938 – 17-1/2 Ton Capacity Can be used with Nos. 1124 and 1130 bearing

pulling attachments or Nos. 679 and 680 pulley pulling attachments. May also be

used with Nos. 1150, 1151, 1153, 1165, or 1166 internal pulling attachments.

No. 939 – 30-Ton Capacity Can be used with Nos. 1126 and 1127 bearing pulling

attachments or No. 680 pulley pulling attachment (two 8012 adapters are required

to connect 680 to puller). Can be used with No. 1165 internal pulling attachment.

SPREAD

REACH

LEG LENGTH

PULLERS

210

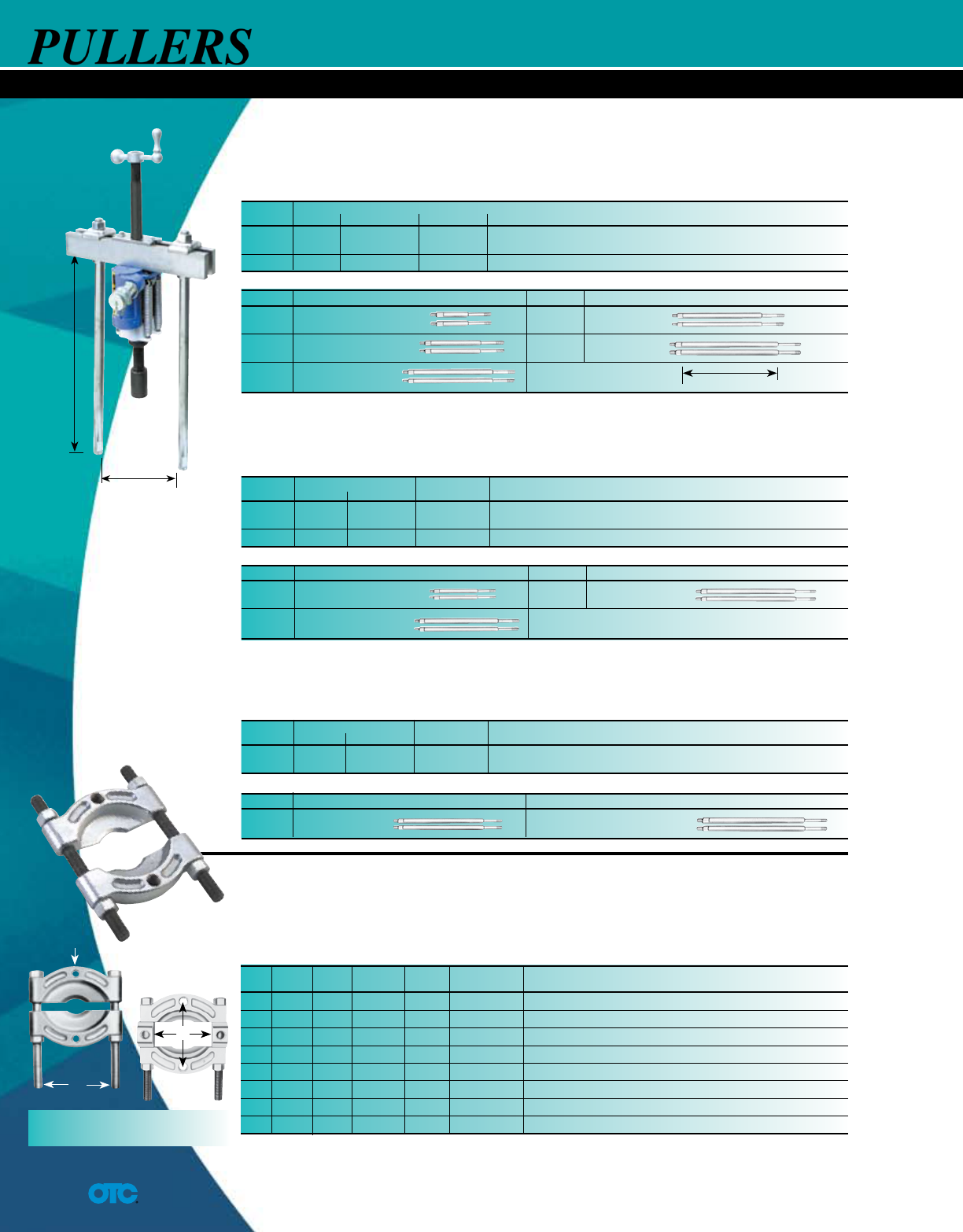

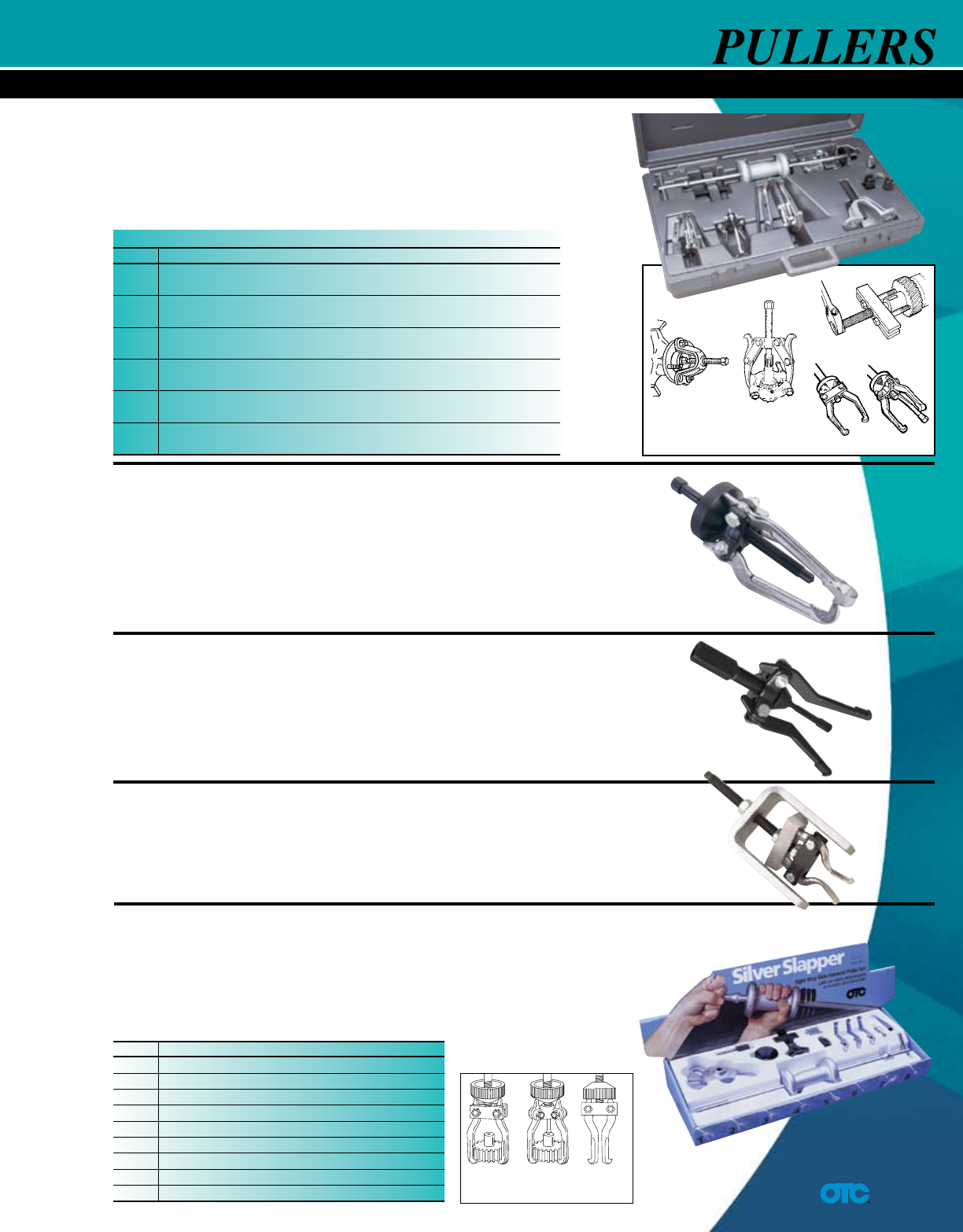

Hydraulic Push-Pullers

Tool MAX. MIN.

No. Spread Spread A B Weight Application

1121 15/16" 1/4" 15/16"–18 1-11/16" 12 oz. Use with puller Nos. 1020, 1022, & 1023.

1122 2" 1/8" 3/8"–16 2-7/16" 1 lb., 4 oz. Use with puller Nos. 1024, 1025, 1026, 1027, 7392, & 7393.

1123 4-5/8" 1/2" 5/8"–18 4-3/8" 5 lbs. Use with puller Nos. 1035, 1036, 1037, 1038, & 927.

1124 5-3/4" 1/2" 5/8"–18 6" 12 lbs. Use with puller Nos. 1035, 1040, 1041, 1042, 1065, 1063, & 938.

1130 9" 1/2" 5/8"–18 6" 12 lbs., 9 oz. Use with puller Nos. 1035, 1040, 1041, 1042, 1065,1063, & 938.

1126 8" 5/8" 1"–14 7-1/8" 19 lbs., 12 oz. Use with puller Nos. 1047, 1043, & 939.

1127 13-3/8" 3/4" 1"–14 10-1/4" 41 lbs., 12 oz. Use with puller Nos. 1047, 1073, & 939.

1128 12-7/8" 5" 1-3/4"–12 13" 100 lbs. Use with puller Nos. 1073, 1079.

A

B

SPREAD

REACH

No. 1062 & 1063

Usable reach equals

leg length minus 4-7/8"

when using leg ends.

No. 1070 & 1071

Usable reach equals

leg length minus 5-7/8"

when using leg ends.

No. 1076

Usable reach equals

leg length minus 10-5/8".

A

A = Thread of tapped hole in adapter.

B = Distance between adjusting screws.

Tool MAX.

No. Reach Spread Screw Size Notes / Weight

1063 18-1/2" 5-3/4"–11-3/4" 1"–8 x 20" Puller with No. 1104 legs, No. 24827 leg ends, No. 4120 hyd. ram,

No. 32118 adjusting screw, and No. 24814 adjusting crank. 38 lbs.

1062 18-1/2" 5-3/4"–11-3/4" 1"–8 x 20" Puller only. 22 lbs.

Extra Legs (pair) for No. 1062, 1063 (Reach equals leg length plus 2" with leg end caps.)

Tool No. Leg Length & Wt. Tool No. Leg Length & Wt.

1107 4-1/2" 1105 22-1/2"

2 lbs., 8 oz. 9 lbs.

1106 9-1/2" 1108 30"

4 lbs., 8 oz. 11-1/2 lbs.

1104 16-1/2" Note: 3/4"–14 thread

6 lbs., 8 oz. on leg upper end.

Tool MAX.

No. Reach Spread Screw Size Notes / Weight

1071 20-1/2" 7"–16-1/4" 1-1/4"–7 x 24" Puller with No. 1110 legs, No. 28390 leg ends, No. 4121 hyd. ram,

No. 34758 adjusting screw, and No. 27198 adjusting crank. 90 lbs.

1070 20-1/2" 7"–16-1/4" 1-1/4"–7 x 24" Puller only. 56 lbs.

Extra Legs (pair) for No. 1070, 1071 (Reach equals leg length plus 2

5

/8" with leg end caps.)

Tool No. Leg Length & Wt. Tool No. Leg Length & Wt.

1109 8" 1111 28"

8 lbs. 22 lbs.

1110 18" Note: 1"–14 thread

15 lbs. on both ends of legs

Tool MAX.

No. Reach Spread Screw Size Notes / Weight

1076 24"

8-1/2"–20-1/2" 1-5/8"–5-1/2

Puller only. 106 lbs.

x 30-3/8"

Extra Legs (pair) for No. 1076 (Reach equals leg length.) Note: 1-1/4"–12 thd. on both leg ends.

Tool No. Leg Length & Wt. Tool No. Leg Length & Wt.

1112 24" 1113 34"

34 lbs. 47 lbs.

LEG LENGTH

No. 1076 – 50-Ton Capacity Can be used with Nos. 1128 and 1129 bearing pulling attachments.

Ends of legs are threaded 1-

1/4"–12. Usable reach: 13-3/8". See pages 211–212 to order threaded

adapters for use with these pullers.

No. 1070, 1071 – 30-Ton Capacity Can be used with Nos. 1126 and 1127 bearing pulling

attachments or No. 680 pulley pulling attachment (two No. 8012 adapters are required to connect

No. 680 to puller). Also may be used with No. 1166 internal pulling attachment. Ends of legs are

threaded 1"–14. Usable reach: 12-

1/8".

Bearing Splitters

No. 1121-1130 These versatile accessories feature “knife-like” edges which are easily placed behind

the part to secure a gripping surface, even when clearances are extremely limited. When used with

an OTC Grip-O-Matic

®

puller, puller jaws grip attachment’s outer edge; when used with a Push-Puller,

puller legs are threaded into the attachment’s two tapped holes.

Hydraulic Push-Puller

No. 1062, 1063 – 17-1/2" Ton Capacity Can be used with Nos. 1124 and 1130 bearing pulling

attachments or No. 680 pulley pulling attachment. May also be used with No. 1154 internal pulling

attachment. Ends of legs are threaded

5/8"–18. Usable reach: 11-5/8".

PULLERS

211

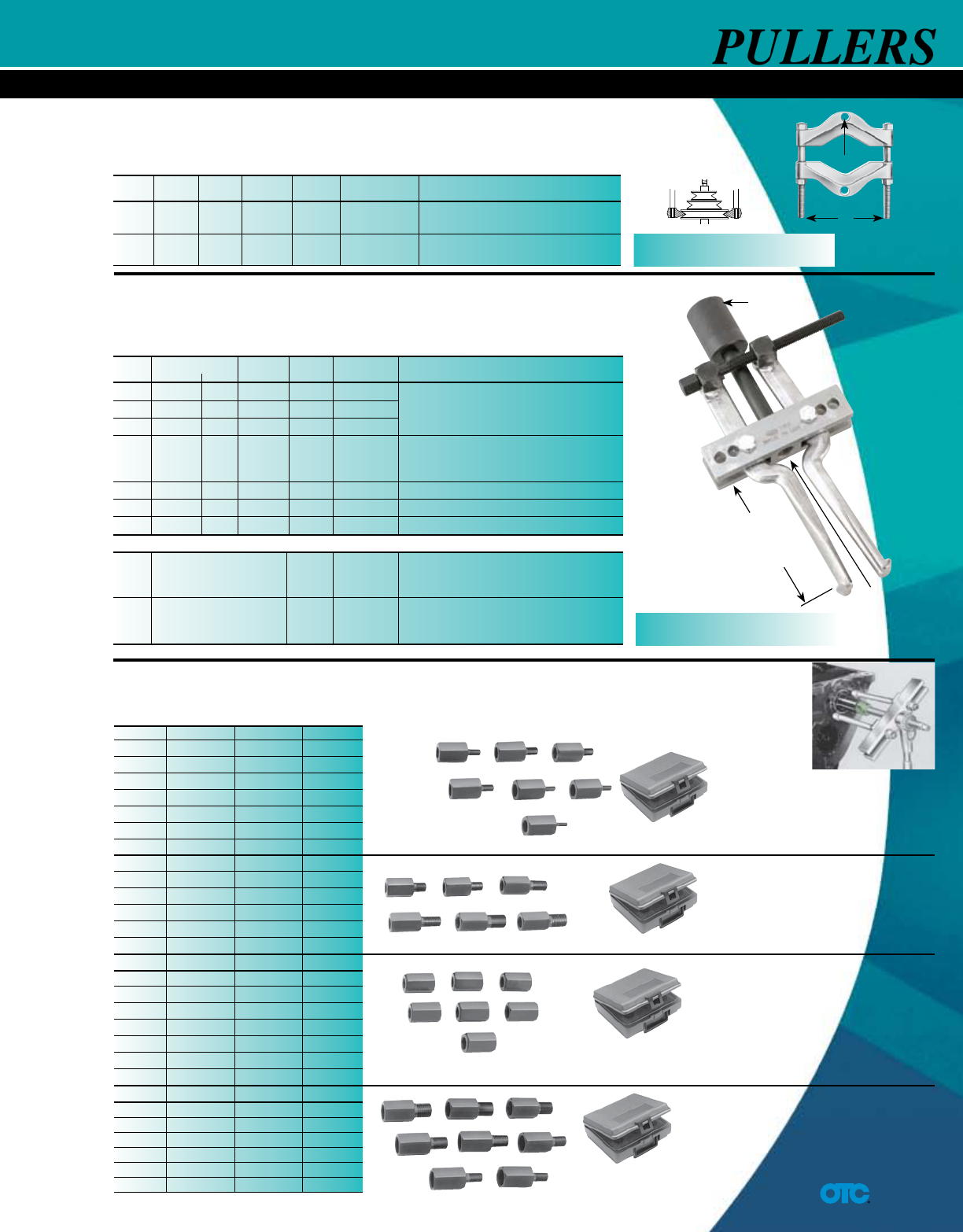

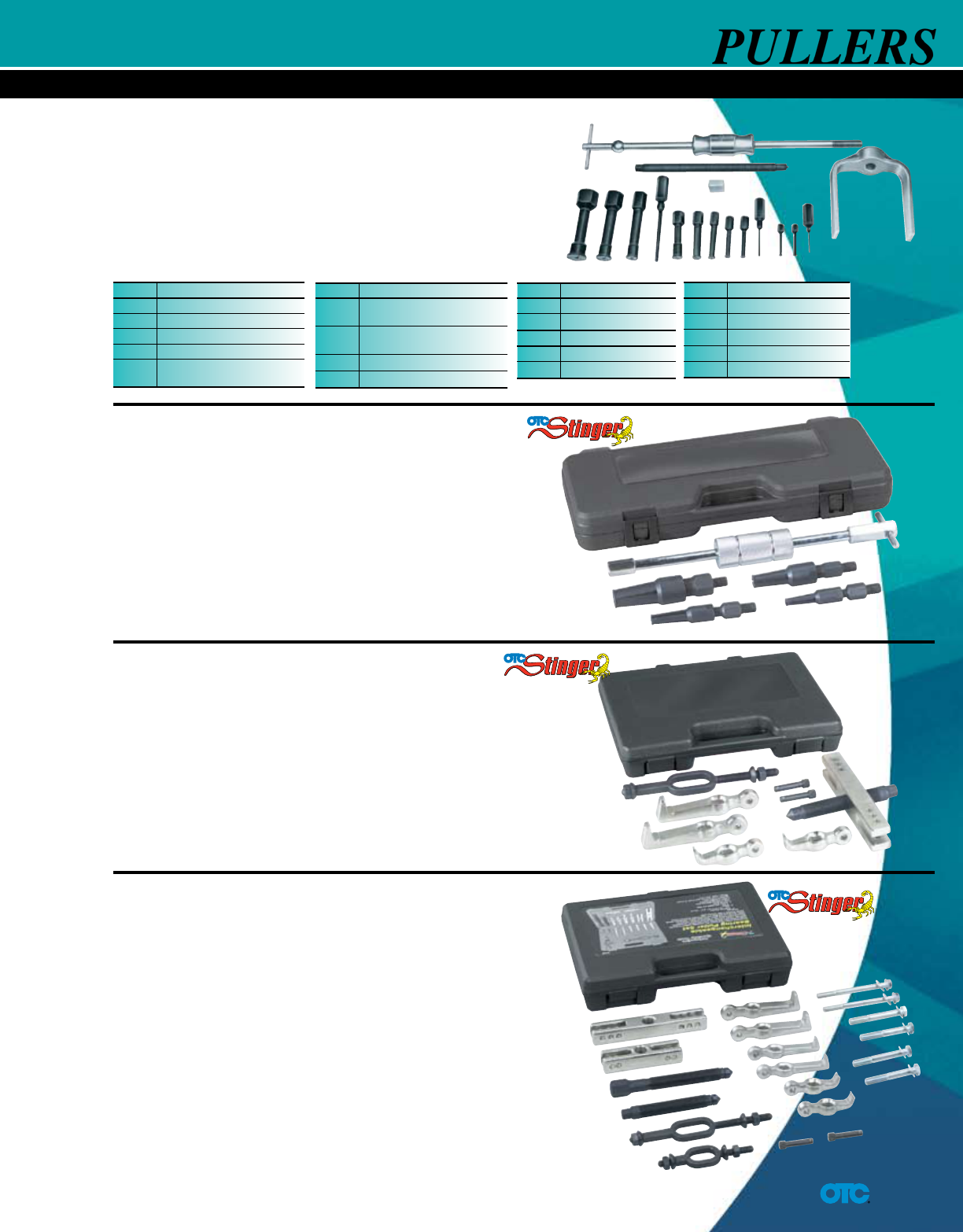

Pulley Pulling Attachments

Tool No. Internal End External End Length

8111 5/8"–18 M6 x 1.0 2-1/4"

8112 5/8"–18 M8 x 1.0 2-1/4"

8113 5/8"–18 M8 x 1.25 2-1/4"

8114 5/8"–18 M10 x 1.25 2-1/4"

8115 5/8"–18 M10 x 1.5 2-1/4"

8116 5/8"–18 M12 x 1.25 2-1/4"

8117 5/8"–18 M12 x 1.75 2-1/4"

8121 5/8"–18 M14 x 1.5 2-1/4"

8122 5/8"–18 M14 x 2.0 2-1/4"

8123 5/8"–18 M16 x 1.5 2-3/4"

8124 5/8"–18 M16 x 2.0 2-3/4"

8125 5/8"–18 M20 x 1.5 2-3/4"

8126 5/8"–18 M20 x 2.5 2-3/4"

Tool No. Std. End Metric End Length

8131 5/8"–18 M6 x 1.0 1-5/8"

8132 5/8"–18 M8 x 1.25 1-5/8"

8133 5/8"–18 M10 x 1.5 1-5/8"

8134 5/8"–18 M12 x 1.75 1-5/8"

8135 5/8"–18 M14 x 2.0 1-5/8"

8136 5/8"–18 M16 x 2.0 1-5/8"

8137 5/8"–18 M20 x 2.5 1-5/8"

Tool No. Female End Male End Length

8141 1"–14 M16 x 1.5 3"

8142 1"–14 M16 x 2.0 3"

8143 1"–14 M18 x 1.5 3"

8144 1"–14 M20 x 1.5 3"

8145 1"–14 M20 x 2.5 3"

8146 1"–14 M22 x 1.5 3"

Tool MAX. MIN.

No. Spread Spread A B Weight Application

679 5-7/8" 1-3/4" 5/8"–18 6" 4 lbs., 4 oz. Use with puller Nos. 1035, 1036,

1037, 1038, and 927.

680 10" 1-5/8" 5/8"–18 10-1/16" 22 lbs., 4 oz. Use with puller Nos. 1039, 1040,

1041, 1063, 1065, and 938.

Pulley Pulling Attachments

Attachment clamps down into V-groove to distribute load. Use with Grip-O-Matic

®

pullers or Push-Pullers.

A

B

REACH

A = Thread of tapped hole in adapter.

B = Distance between adjusting screws.

1150-1166

A

B

Internal Pulling Attachments

Approved by leading bearing manufacturers, OTC’s internal pulling attachments remove

bearing cups, oil seals, bushings, and other parts from blind holes quickly and easily. Each

attachment is designed for use with a corresponding Push-Puller or slide hammer assembly.

A = Thread of tapped hole in adapter.

B = Internal thread of tapped cross block.

Metric Adapter Sets*

No. 8110-8140 Add metric capability to your Push-Puller legs or forcing screws! Four

different sets to choose from. A storage/organizer case is included with each set.

NOTE: The

adapters in

each of these

sets are

also available

separately.

No. 8140 – External/

internal metric

adapter kit.

Wt., 5 lbs., 5 oz.

No. 8130 – External/

internal adapter kit.

Wt., 2 lbs.,12 oz.

No. 8120 – External/internal

metric adapter kit. Wt., 3 lbs.

No. 8110 – External/internal

metric adapter kit. Wt., 3 lbs.

Use with Nos. 927 and 938 Push-Pullers,

1155 and 1156 slide hammer pullers,

or 24832 and 24833 puller screw.

Tool JAW

No. Spread Reach A B Weight Application

1153 1-1/2"–5" 2-1/8" 1"–14 5/8"–18 4 lbs., 4 oz.

1150 1-1/2"–6" 4" 1"–14 5/8"–18 4 lbs., 4 oz.

1152 1-1/2"–6" 4" – 5/8"–18 3 lbs., 8 oz.

1151 1-1/2"–7" 5-1/4" 1"–14 5/8"–18 4 lbs., 8 oz. Use with Nos. 927 and 938 Push-Pullers,

1155 and 1156 slide hammer pullers, or

24832 puller screw.

1165 3"–9" 5-7/8" 1-1/2"–12 1"–14 13 lbs., 8 oz. Use with No. 939 Push-Puller.

1154 1-1/2"–9" 4" 1"–8 5/8"–18 4 lbs., 8 oz. Use with No. 1063 hyd. Push-Puller.

1166 3"–9" 5-7/8" 1-1/4"–7 1"–14 13 lbs., 8 oz. Use with No. 1071 hyd. Push-Puller.

Puller Screws

24832 13-3/4" long 5/8"–18 1 lb. Use with Nos. 1150, 1151, 1152, and 1153.

Acts as a regular forcing screw when threaded

directly into the block of pulling attachment.

24833 5-1/2" long 5/8"–18 6 oz. Use with Nos. 1150, 1152, and 1153. Acts

as a regular forcing screw when threaded

directly into the block of pulling attachment.

PULLERS

212

External-Internal Threaded Adapters

Tool Set No.

No. 8074 8075 8076 Dia.“A” Dia.“B”

8057

•

•

1" 3/4"

8058

•

•

1-1/8" 7/8"

8059

•

•

1-1/4" 1"

8060

•

•

1-3/8" 1-1/8"

8061

•

•

1-5/8" 1-1/4"

8062

•

•

1-3/4" 1-3/8"

8063

•

1-7/8" 1-1/2"

8064

•

2" 1-5/8"

8065

•

2-1/8" 1-3/4"

Tool Set No.

No. 8074 8075 8076 Dia.“A” Dia.“B”

8066

•

2-3/8" 1-7/8"

8067

•

2-1/2" 2"

8068

•

2-5/8" 2-1/8"

8069

•

2-3/4" 2-1/4"

8070

•

2-7/8" 2-3/8"

8071

•

3" 2-1/2"

8072

•

3-1/4" 2-3/4"

8073

•

3-1/2" 3"

Tool Internal Internal

No. End “A” End “B”

8035* 1/2"–20 5/8"–18

8036* 1"–14 1"–14

8037 5/8"–18 5/8"–18

8038 5/8"–18 3/4"–16

8039 5/8"–18 7/8"–14

Tool Internal Internal

No. End “A” End “B”

8040 5/8"–18 1"–14

8041 5/8"–18 1-1/8"–12

8042 5/8"–18 1-1/4"–12

8043* 5/8"–18 1-1/2"–12

*Not included in set No. 8044. Order sepa-

rately. All adapters are available separately.

Tool No. “A” “B” “C” (60°) “D” (60°)

8050 1-1/2" 3/4" 3/8" 7/16"

8051 1-1/4" 3/4" 3/8" 3/8"

8052 1" 3/4" 3/8" 5/16"

Tool Internal External

No. End End Length

206437 1/2"–20 5/8"–18 2-1/4"

8000 5/8"–18 1/4"–20 2-1/4"

8001 5/8"–18 5/16"–18 2-1/4"

8002 5/8"–18 7/16"–14 2-1/4"

8003 5/8"–18 7/16"–20 2-1/4"

8004 5/8"–18 3/8"–24 2-1/4"

8005 5/8"–18 3/8"–16 2-1/4"

8006 5/8"–18 1/2"–20 2-1/4"

8007 5/8"–18 1/2"–13 2-1/4"

8008 5/8"–18 9/16"–18 2-1/4"

8009 5/8"–18 9/16"–12 2-1/4"

8010 5/8"–18 5/8"–11 2-1/4"

8013 5/8"–18 3/4"–16 2-1/4"

8015 5/8"–18 3/4"–10 2-1/4"

8017 5/8"–18 7/8"–14 2-1/4"

8018 5/8"–18 7/8"–9 2-1/4"

Tool Internal External

No. End End Length

8019 5/8"–18 1"–14 2-1/4"

8022 5/8"–18 1/8" pipe 2-1/4"

8012 1"–14 5/8"–18 3-3/16"

8011 1"–14 5/8"–11 2-1/2"

8014 1"–14 3/4"–16 2-1/2"

8016 1"–14 3/4"–10 2-1/2"

8020 1"–8 5/8"–18 3"

8021 1"–8 1"–14 3"

8023 1-1/4"–12 1"–14 4-1/2"

8024 1-1/4"–12 1-3/4"–12 4-3/4"

8025 1-1/4"–7 5/8"–18 4"

8027 1-1/4"–7 1"–14 4"

8029 1-5/8"–5

1

/2 1"–14 4"

8028 1-5/8"–5

1

/2 1"–8 4"

8030 3/4"–16 5/8"–18 2-1/4"

A

B

Tool No. “A” “B” “C” (60°) “D” (60°)

8053 3/4" 3/4" 1/4" 1/4"

8054 5/8" 5/8" 1/4" 1/4"

8055 5/8" 5/8" 3/16" 3/16"

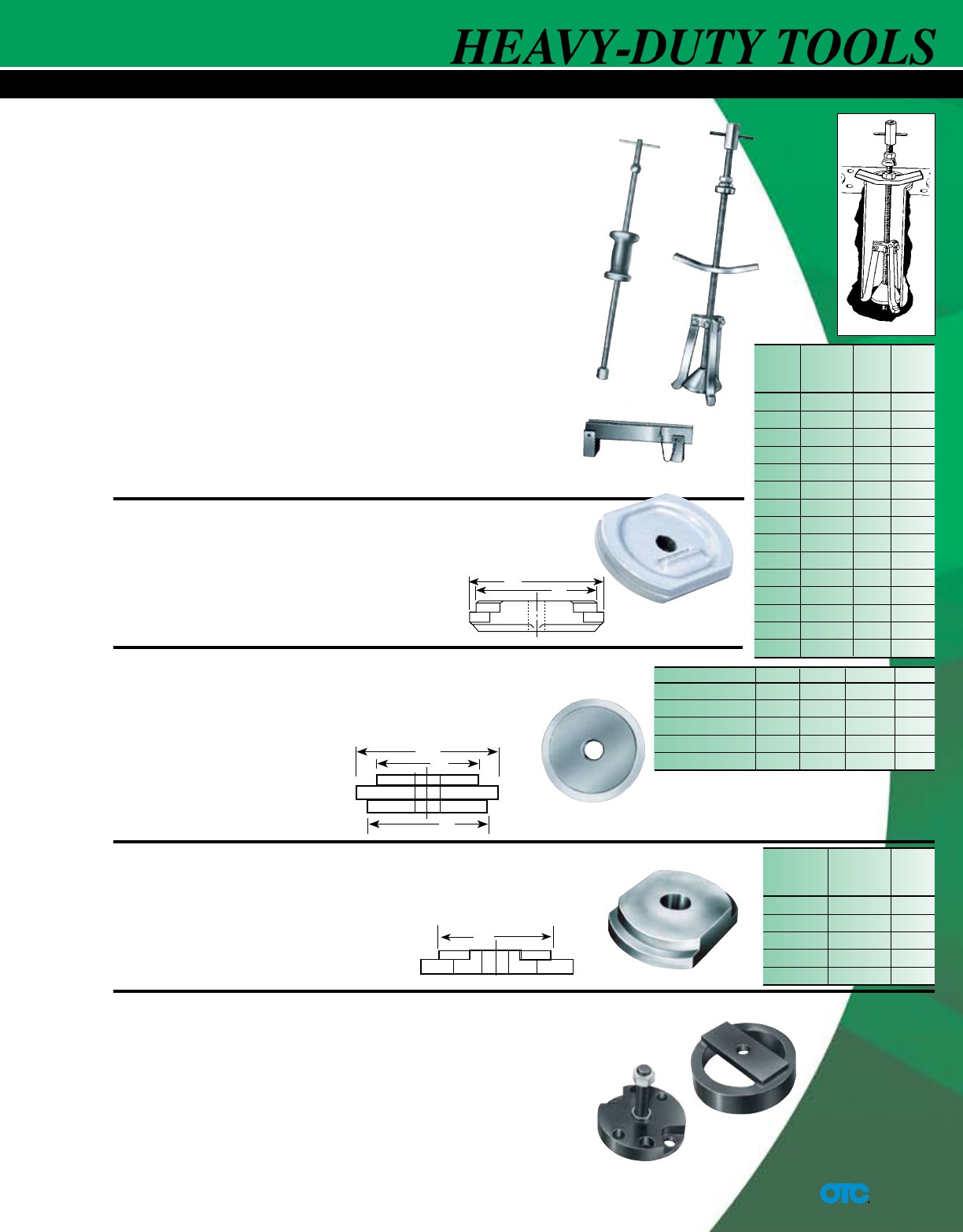

External-Internal Threaded Adapters

For use on the ends of Push-Puller legs or forcing screws when

pulling shafts, bearing caps, pinions, etc.

A

B

Step Plate Adapter Sets

Necessary for pulling and installing bearings, gears, or other

parts found on hollow shafts or housings. They may be used with

Grip-O-Matic

®

pullers and Push-Pullers

®

, as well as shop presses.

All adapters are available separately.

No. 8074 – Wt., 1 lb., 5 oz. No. 8075 – Wt., 5 lbs., 5 oz.

No. 8076 – Wt., 10 lbs., 6 oz.

Shaft Protector Set

Designed to protect shaft centers from distortion when extreme

pressures are applied with either Grip-O-Matic

®

pullers or

Push-Pullers. Shaft protectors are available separately.

No. 8056 – Shaft protectors. Wt., 1 lb., 2 oz.

Internal Threaded Adapter Set

For use on the ends of Push-Puller legs or forcing screws to aid

in the removal and installation of shafts, axles, and housings.

No. 8044 – Internal adapters. Wt., 3 lbs.

PULLERS

213

Reversible-Jaw Slide Hammer Pullers

Slide Hammer Pullers with

Cup Pulling Attachments

These pullers combine a basic slide hammer unit with a No. 1152

internal pulling attachment (described on page 211). Ideal for

removing bearing cups, outer races, and oil seals from blind holes.

Upon removal of the internal pulling attachment, the basic slide

hammer unit, which has a 5/8"–18 threaded end, may be used with

various adapters for a multitude of pulling jobs.

No. 1157 – Slide hammer puller, consisting of an 1152 internal pulling attachment

and an 1156 basic slide hammer unit with a 2-1/2 lb. hammer. Wt., 9 lbs., 12 oz.

No. 1158 – Slide hammer puller (not shown), consisting of an 1152 internal pulling

attachment and an 1155 basic slide hammer unit with a 5 lb. hammer.

Wt., 12 lbs., 4 oz.

Reversible-Jaw Slide Hammer Pullers

Here are two extremely versatile pullers, which will accomplish many

pulling jobs involving gears, bearings, outer races, grease retainers,

oil seals, etc. Either two or three puller jaws may be used to handle

“inside” pulling jobs such as bearing cups and outer races, as well

as regular “outside” pulling jobs. The basic slide hammer unit can be

removed and used independently. The No. 1177 slide hammer puller

has a 5 lb. hammer, and the No. 1176 has a 2-1/2 lb. hammer.

No. 1176 – Puller with 2-1/2 lb. hammer, 2-way and 3-way head, 27" long.

Wt., 8 lbs.

No. 1177 – Same as 1176, except has a 5 lb. hammer. Wt., 10 lbs., 8 oz.

Tool I.D. Spread Wt.

No. Reach Min. Max. (lbs./oz.)

1170 3/4" 1/2" 1-1/2" 4 / 14

1171 1" 7/8" 2-1/8" 4 / 14

1172 1-3/4" 1/2" 2" 4 / 14

Basic Slide Hammer Units

May be used with an OTC internal pulling attachment (page 211),

or with internal or external-internal threaded adapters (page 212).

No. 1155 – Basic slide hammer unit is 24" long with a 5 lb. hammer and a

5/8"–18 threaded end. Wt., 7 lbs., 4 oz.

No. 1156 – Basic slide hammer unit is 24" long with a 2

-

1/2 lb. hammer

and a 5/8"–18 threaded end. Wt., 4 lbs., 12 oz. (not shown)

No. 6501 – Basic slide hammer unit is 17" long with a 1-3/4 lb. hammer

and a 1/2-20 threaded end. Wt., 3 lbs.

Pilot Bearing Pullers

These very versatile pullers are built specially for

inside pulling jobs, and particularly for removing

flywheel pilot bearings on automobiles, trucks,

and tractors. Also very practical for pulling motor,

generator, and magneto bearings.

Special Slide Hammer Puller

Ideal for pulling jobs in very close quarters, as in removal of small-bore

bushings, bearings, oil seals, etc. Internal pulling attachment has a jaw

spread of 1/2" to 1-3/8", adjusted by turning the slide hammer handle.

Handle end has a 1/2"–20 thread.

No. 1173 – Slide hammer puller with head assembly. Wt., 3 lbs., 8 oz.

No. 1174 – Head assembly only. Wt., 10 oz.

6501

2-Jaw Spread 3-Jaw Spread

Inside Outside Inside Outside Overall

Min. Max. Min. Max. Min. Max. Min. Max. Length

1-1/4" 3-1/2" 1" 4-1/2" 1-1/2" 4-1/4" 1-1/2" 4-1/2" 27"

Spread Overall

Min. Max. Reach Length

1-5/8" 6" 4" 28"

1155

1173

5028

Slide Hammer Puller

Just 8-1/2" long to fit into tight spots, but its 1-1/2 pound hammer

gives you a little extra muscle for stubborn jobs. It’s perfect for

pulling injector nozzles. The shank is threaded 1/2" –20 and has a

5/8" –18 threaded adapter included. Works with many OTC pulling

attachments.

No. 5028 – Slide hammer puller. Wt., 2 lbs.

PULLERS

214

Grip Wrench Adapters & Bearing Pullers

Grip Wrench Adapters

For grip wrenches using single- or double-lead thread adjusting screw.

Adapter threads onto a slide hammer with a 5/8"–18 thread. Grip wrench

threads onto a 7/16"–14 end of adapter for pulling use.

No. 205378 – Grip wrench adapter with single lead thread. Wt., 4 oz.

No. 218875 – Grip wrench adapter with double lead thread. Wt., 4 oz.

1028

1031

Differential Bearing Pullers

For removing differential side carrier bearings on a wide variety of

passenger cars and light trucks. Use with step plate adapter Nos. 8060,

8061, 8063, and 8064. (Step plate adapters are not included with 1028

or 1031. See page 212.)

No. 1028 – Puller with a 3-1/2" maximum reach, 1-1/4" to 4-1/2" spread.

Primarily for servicing Ford products. Wt., 1 lb., 13 oz.

No. 1031 – Puller with a 3-1/4" maximum reach, 6" maximum spread.

For serv

icing most General Motors, American Motors, and Chrysler

products. Wt., 2 lbs.

Specifications

Reach: 1-5/8"

Spread: 2-5/8" on inside holes in crossbar

3-3/8" on outside holes in crossbar

Forcing screw: 3/4"-16 mm x 6-11/16" lg.

Adapter sizes: 15/16" to 1-3/4" diameter

Differential Side Bearing Pullers

•

Use to remove differential side carrier bearing. Works on a wide

variety of cars and light-duty trucks.

•

Includes four step plate adapters to fit carrier bearings.

•

Reach: 1-5/8". Spread: 2-5/8" to 3-3/8". Forcing screw is

3/4"-16 mm x 6-11/16" lg.

Set includes:

Part No. Description

4520-1 Forcing Screw / Cross Block Assembly

4520-2 Puller Jaws / Pins (set of two each)

4520-3 Puller Jaws Retaining Yoke

4520-4 Step Plate Adapters (set of four)

15/16" – 1-11/32" diameter 1-1/8" – 1-1/2" diameter

1-1/4" – 1-5/8" diameter 1-1/8" – 1-3/4" diameter

No. 4520 – Differential side bearing puller. Wt., 4 lbs., 10 oz.

4520

Ten-Pound Slide Hammer Puller

This heavy-duty slide hammer puller gets tough with those really

stuck parts. It has all the features of our smaller versions – heat treated,

24" long, and a 5/8"–18 threaded end to adapt to any of OTC’s pulling

attachments. The difference is the ten-pound hammer that gives you the

extra muscle for really stubborn pulling jobs.

No. 7703 – Ten-pound slide hammer puller. Wt., 12 lbs., 5 oz.

Sliding Hammers

No. 22185 – 2-1/2 lb. sliding hammer.

No. 34331 – 5 lb. sliding hammer.

22185

34331

7703

464 465

OTC “GripLock” Pullers

Manufactured to our rigorous specifications to ensure the quality

professionals expect from OTC

• Pressure bearing yoke cap holds jaws in place for ease of set

up - in any orientation.

• 2 or 3 Jaw application.

• Both External and Internal Pulling Action.

• “Live Center” action forcing screw.

• Professional finished for long lasting durability…

No. 464 – Puller with a 4" maximum reach, 3" to 4" spread.

Wt., 3 lb., 4 oz.

No. 465 – Puller with a 7" maximum reach, 3" to 7" spread.

Wt., 7 lb., 13 oz.

PULLERS

215

Slide Hammer Puller Sets

Multipurpose Puller Set

This assortment of puller tools gives you a wide range of job versatility.

You get a 5 lb. slide hammer puller, hub puller, two sizes of OTC Grip-

O-Matic

®

jaw-type pullers, a bearing pulling attachment, plus a cross-bar

gear and pulley puller, all contained in a handy plastic storage case.

No. 1181 – Multi-purpose puller set. Wt., 25 lbs.

Set No. 1181 consists of:

No. Description

1177

Slide hammer puller with a 5 lb. hammer, 2-way and 3-way heads. Reversible: either

two or three jaws may be used to handle both “inside” and “outside” pulling jobs.

7208A Front hub puller for servicing front-wheel-drive cars. Includes a spare locknut,

which permits use with a No. 1177 slide hammer for rear axle flanges.

1023 2-ton combination 2- or 3-jaw Grip-O-Matic puller. Has 3-3/8" max. reach,

4-3/4" max. spread.

1027 5-ton combination 2- or 3-jaw Grip-O-Matic puller. Has 5-1/2" max. reach, 7" max.

spread.

7393 Bar-type gear and pulley puller with a 5-1/2" long screw. Includes two hex head

cap screws, 3/8"–16 x 3" long. Spread range: 1-1/2" to 4-1/4".

1122 Bearing pulling attachment for use with No. 1027 and No. 7393 pullers. Has 2"

max spread, 1/8" min. spread.

(1122)

(7208A)

(1177)

(7393)

Cone-type Puller

Reversible jaws permit handling of both internal and external pulling jobs. The

2-way/3-way head permits assembly of puller to suit the job at hand. Turning

the cone on the puller head securely locks its jaws on the part to be removed.

Puller reach: 2-7/8"

2-jaw spread: 3-jaw spread:

Inside: 1-1/2" to 4-1/2" Inside: 1-1/2" to 4-3/4"

Outside: 3/4" to 5" Outside: 1" to 4-1/2"

No. 1184 – Cone-type puller. Wt., 2 lbs., 6 oz.

Bearing Cup Remover

Ideal for servicing hubs on today’s popular front-wheel-drive small cars.

The cone holds the jaws in place during pulling. No. 7136 is perfect

for pulling internal bearing cups, seals, bushings, etc. Jaw spread:

15/16" to 3-1/4", reach to 3-1/2". Use with any slide hammer having a

5/8"–18 thread (OTC No. 1155 or No. 1156 or the No. 927 Push-Puller).

No. 6542 – Universal bearing cup remover. Wt., 1 Ib., 8 oz.

Pilot Bearing Pullers

Designed to pull flywheel pilot bearings in close quarters where a slide

hammer cannot be used. Operates on many models with engine in chassis.

No. 7318 – Pilot bearing puller. Capacity:

1/2"

to 1-

1/2"

. I.D. reach:

3/4"

. Wt., 3 Ibs.

, 7 oz.

No. 7319 – Pilot bearing puller. Capacity:

7/8"

to 2

"

. I.D. reach: 1". Wt., 3 Ibs., 8 oz

.

Set No. 1179 consists of:

No. Description

1155 Slide hammer w/5 lb. hammer

7372 Rear axle pulling attachment

24544 3-way cross-head

24545 Cone

27241 2-way cross-block

27315 Puller hook attachment